On-site management of electro-coating

In order to ensure the normal progress of production, the stability of electrophoretic bath solution and the quality of coating, it is necessary to strengthen the on-site management of electrophoretic coating production. Two-sided management includes process management, production management and equipment management. The electrophoretic coating production site needs to scientifically manage the electrophoretic paint tank liquid, electrophoretic coating equipment and supporting equipment, production environment and conditions, and make records; if abnormal phenomena are found, immediate measures should be taken to solve them.

(1) Electrophoretic coating process management

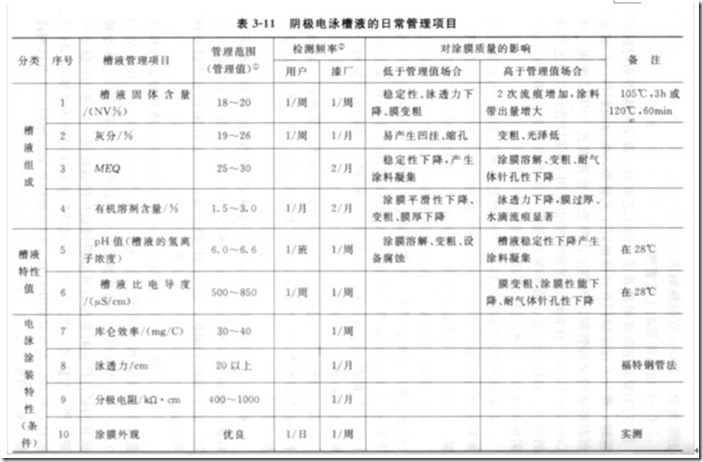

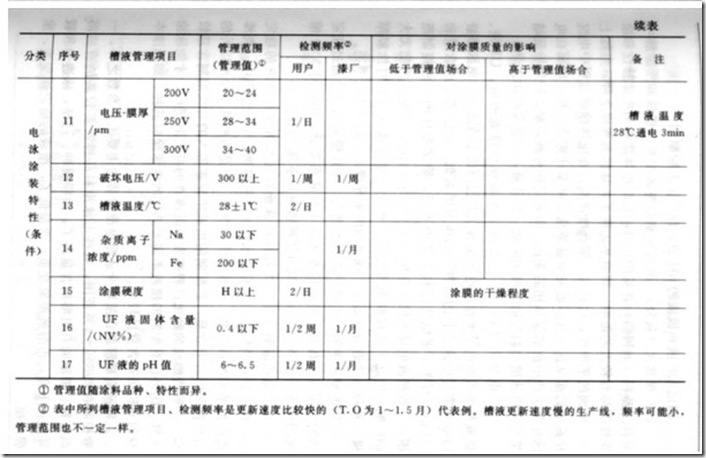

It mainly conducts scientific management of electrophoretic paint tank solution, coating process parameters, and coating quality. Nowadays, not only the coating factory does a good job in process management on site, but also the electrophoretic coating supplier is also responsible for the overall management of the bath solution. Now learn from foreign countries Professional management mode (CPU management, ie CostPerUnit), CPU management is also adopted in many domestic coating lines. Process management items, target management values, detection frequency, etc., are introduced by taking HB-2000 cathodic electrophoretic coating of Kansai Paint Company as an example (see Table 3-11).

Daily detection and adjustment of process parameters at the electrophoretic coating site: according to the determination of the solid content, pH value, electrical conductivity, pigment-base ratio (ash content), organic solvent content, pH value and solid content of the bath solution and other parameters As a result, adjustment management is performed.

(1) Solid content (NV) During the electrophoretic coating production process, the electrophoretic coating is continuously consumed with the production (or through the increase of the coated area), so that the NV of the bath solution gradually decreases. In order to ensure the stability of the coating quality, the NV The range of variation should be small (±1% of the standard value); each shift should be supplemented with electrophoretic paint according to the number of passed workpieces (coating area), and then corrected once a week according to the actual measurement results.

In daily production, the possibility of the NV of the bath liquid rising is very small; unless the shutdown time is long, the NV rises due to the volatilization of water and solvent during the circulation stirring process; it can be adjusted by adding an appropriate amount of pure water.

The purpose of detecting the solid content of UF liquid is to detect the technical state and operation status of the UF device. If it is too high (NV>0.5%), it is necessary to check the formation of low-molecular paint film or high impurity ions in the bath liquid; or UF membrane leakage, poor technical condition of UF components, etc.

(2) PH value The PH value of the electrophoretic paint bath is an important process parameter that directly affects the bath liquid and the water solubility of the resin base material. It should be strictly controlled within the range of 0.05~0.1 of the specified value of the process, and it will be too high or too low. It causes the instability of the bath solution and the quality problem of the electrophoretic coating film. In severe cases, it even causes the film-forming resin to precipitate or condense, block the UF film or the pole cover, and produce a large amount of sediment. Therefore, it is necessary to strengthen the careful management of the PH value of the electrophoretic paint tank solution on site, observe its change law, and take measures such as adding corresponding neutralizers or electrode discharge solutions to adjust according to the test results.

Measuring the pH value of UF liquid and polar liquid is only for process control.

(3) Pigment-base ratio (ash content) Pigment-base ratio refers to the ratio of pigment to base material (such as resin) content in electrophoretic coatings, baths and dry coating films. Big impact, such as high pigment-base ratio, the film thickness of swimming coating decreases, and the voltage increases; the smoothness, pinhole resistance and shrinkage of the paint surface are improved. In the electrophoretic coating process, the pigment-to-base ratio of the electrodeposition coating film is often not exactly the same as that of the original electrophoretic paint. Therefore, the pigment-to-base ratio changes during the electrophoretic coating production, which requires regular inspection and adjustment. To control the test results, properly increase the amount of paint base (such as emulsion) or color paste when feeding into the electrophoresis tank.

(4) Conductivity (μs/cm) On-site detection of the conductivity of bath solution, UF solution, polar solution and pure water in electrophoretic coating is one of the means of electrophoretic coating process control. The conductivity of the electrophoretic bath is related to the type of electrophoretic coating, the level of solid content, the content of impurity ions and the pH value. Depending on the type of electrophoretic coating, a good range of process control is determined. Generally, the conductivity of the bath is relatively high. Small changes (such as ±100μs/cm) have no major impact on the performance of the coating film, so the process control range is wide. Too high or too low conductivity of the bath will affect the thickness, appearance and throwing power of the coating film. With the increase of the conductance of the bath, the throwing power will also increase.

If the conductivity of the bath solution exceeds the specified upper limit or is too high due to the increase of the content of impurity ions in the bath solution, it can be reduced by replacing the UF solution with pure water. Then the conductivity of the bath can be reduced by 100μs/cm.

(5) Organic solvent content In order to improve the water solubility of the electrophoretic coating and the stability of the bath, the formula of the electrophoretic coating is added with a hydrophilic organic solvent. Generally, medium and high boiling point ester and alcohol solvents are used. The solvent content of the bath generally refers to the percentage of organic solvents other than water in the bath. The organic solvent content of the original paint in the newly prepared bath is relatively high. Generally, the workpiece can be swim-coated after the organic solvent with a low boiling point is volatilized during the aging process of the bath. There are electrophoretic coating varieties that do not need to be cured in the prepared bath solution abroad, that is, the organic solvent content of the original paint itself is already small.

The organic solvent content of the bath solution is one of the main process parameters of electrophoretic coating, which is generally controlled in the range of 2.5~4%. Some electrophoretic coating varieties require a higher organic solvent content. If the organic solvent content of the bath is high, the coating film will be bloated and too thick, the throwing power and storage voltage will decrease, and the remelting phenomenon will become heavier; if the content is low, the stability of the bath solution will become poor, and the coating film will dry out.

Since the organic solvent pollutes the atmosphere after volatilization, from the perspective of environmental protection, the development trend is to improve the water solubility of the resin without the use of organic solvents.

槽液的有机溶剂含量的测定采用气相色谱仪。According to测定结果,再向槽液中补加适量的相应溶剂。

(二)电泳涂装设备管理要点

电泳涂装设备(装置)的管理基本是观察机械、机器的磨耗和劣化,以及动作的变化,记录数据的变化,确认有异音、异臭,实施检修和保全等管理要点参照表3-12所列内容。

表3-12电泳涂装设备的管理要点

类别 | 项目 | 检查频率 | 备注(要领) |

输送链 | 运输链速度/(m/min) 油污、尘埃滴落状况 | 2次/日 1次/日 | 定速输送,无脉动 防止油污、尘埃的滴落 |

涂装数量 | 生产数量(车身台数) | 每日记录 | |

涂料补给和调整装置 | 涂料补给量 补加溶剂等调整剂量 | 每日记录 每日记录 | 查看补给量是否过少,确保消耗量/补给量一定(槽液NV稳定) 调整剂品种和补加确切否 |

电泳主槽状态 | 液面落差/cm 液面的泡沫 液面流速/(m/s) | 1次/日 1次/日 1次/日 | 落差>5cm将产生泡沫是否过多 正常否 |

循环系统 | 泵、管道的泄漏 泵的异常声音 各部位的压力 过滤器的压差 | 1次/日 1次/日 1次/日 1次/日 | 应无泄漏,确保槽液循环量 应无异常声音及振动 正常否 正常否 防止涂膜的颗粒弊病 |

UF装置 | UF液的总透过量 各UF元件的透过量 UF液的状态 UF装置进、出口压差 过滤器的压差 | 1次/日 1次/日 1次/日 1次/日 1次/日 | 透过量正常否,过滤量稳定化,防止UF膜老化 应不浑浊 正常否 正常否 |

极液系统 | 循环量 极液电导(μs/cm) 极液状态 | 1次/日 1次/日 1次/日 | 确保槽液的PH稳定,极液电导高的场合排除剩余酸 应不浑浊 |

直流电源 | 直流整流器运行 直流电压/V 电泳电流/A | 1次/日 2次/日 2次/日 | 确保电泳直流电源供给稳定 |

槽液温度 调整系统 | 冷温水热交换器 制冷机组 室外冷却塔 | 1次/日 1次/日 1次/日 | 进行槽液温度调整(冷却) 确保槽液温度稳定 |

电泳后清洗设备 | 水洗压力 水洗状态 | 1次/日 1次/日 | 喷嘴有无堵塞、方向正常否,水洗效果正常否(有无二次流痕) 回收涂料状况 |

纯水装置 | 水质(μs/cm) 制水量 | 1次/日 1次/日 | 有无纯度下降现象,确保制水量 |

电泳前的表面处理 | 表面状态 滴水电导(μs/cm) 磷化的特性值 | 1次/日 1次/日 1次/日 | 防止车身从前处理带来杂质离子和其他污物进电泳槽 |

烘干室 | 温度(工件温度) 烘干 | 2次/日 | 检查记录正常否 每周测一次随行温度曲线 |

(三)电泳涂装的生产管理

它包括生产状况、设备运行、现场环境卫生、生产安全等管理,其管理要点如下:

①记录每班、每日、每月的产量(以产品数量或涂装面积计)。

②Record the operating status of the equipment, and calculate the daily equipment operating rate and effective production rate (or effective utilization rate of working hours).

③ Record the consumption of electrophoretic coatings and various raw and auxiliary materials, compare with the material consumption quota, and find out the reasons for the excess, and strive to improve the utilization rate of materials.

④Record and count the water, electricity, fuel and other energy consumption of the electrophoretic coating line, and continuously improve the energy saving and emission reduction level of coating (expressed by energy consumption per unit coating area and CO2 emission).

⑤Ensure that the electrophoretic coating line runs continuously after starting production, and the production line runs empty before stopping or stopping production, so as to avoid secondary corrosion, coating film redissolution and over-drying and other coating quality problems.

⑥Strengthen the management of electrical equipment, and strictly prohibit non-operating personnel from entering the electrophoretic coating room during operation to ensure production safety.

⑦ Strictly implement the cleaning system of the production environment and the cleaning of coating equipment to ensure that the production status is clean and dust-free

⑧ Raw materials and wastes (such as waste containers, rags, etc.) should be placed in a fixed location, neatly placed, the quantity stored on site should be controlled, and wastes should be cleaned up in time before get off work (or regularly).

⑨The quality, equipment and safety accidents produced on site should be analyzed, studied and eliminated in time, and major forces should be organized to tackle key problems and records should be made.

- 1Characteristics and process of electro-coating

- 2Electro-coating limitations and benefits

帅长红 - 《电泳涂装新工艺新技术》

- 3Thickening (precipitation) mechanism of electro-coating film

帅长红 - 《电泳涂装新工艺新技术》

- 4Electro-coating and its principle

帅长红 - 《汽车车身涂装新工艺新技术》

- 5Main Features of Electro-Coatings

- 6Causes and treatment methods of common defects of films in electro-coating

- 7Electro-coatings Determination of ash content and color-to-base ratio

- 8Maintenance and management of electro-coating ultrafilter

- 9Management summary of electro-coating