Production process of alkyd blended paint

Alkyd blend paint is processed from alkyd resin, pigment, extender pigment, drier and solvent, etc. It has good color and luster and can be used as exterior paint. The production process is as follows:

1. Heat the coal tar in an iron pot at 150-160 degrees Celsius to drive water, stir until the surface is calm and bright, no soda and bubbles, remove impurities at the bottom, cool down and use immediately.

2. Preparation of rubber emulsion: Cut the glue sub-sheets used for SI002 lining into small pieces of 10 by 10mm, put them into a sealed reaction kettle, add 200# solvent gasoline to stir the solvent. Rubber material: gasoline = 1:3~4 weight ratio. It is used for sealing equipment after complete melting.

3. Heat the epoxy resin at 40-50 degrees Celsius to make it flow easily, and add it to the reaction kettle. Add SI002 sol solution, heat at 70-80 degrees Celsius and stir for 10-20 minutes, add ethyl acetate and stir for 30-60 minutes. The temperature is kept at 70-80 degrees Celsius.

4. Add dehydrated tar and stir for 10 minutes, add talcum powder and mica powder and stir for 30 minutes, then add aluminum powder slurry.

5. Use a gear pump to circulate for 10-20 minutes to cool down and discharge the material for packaging.

- 1Introduction of Working Principle and Application of Electric Oscillator Stirrer

- 2A Brief Discussion on the Difference between Disperser and Stirrer

- 3Common faults and solutions of Disperser Stirrer

- 4Explain the difference between Stirrer and Disperser

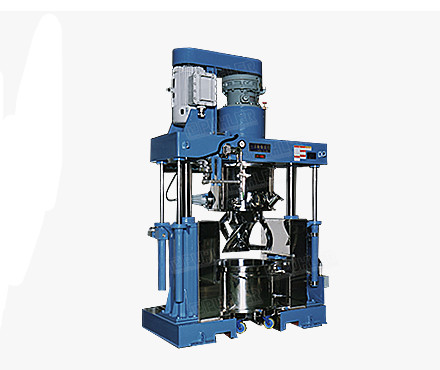

- 5Planetary mixer selection skills

- 6Features of acrylic latex paint

- 7When do you need to use a disperser instead of a mixer? Difference between disperser and mixer

- 8Several low-end high-speed stirring and dispersing machines that meet GB/T 21868.3 standards

- 9Preparation of Photosensitive Electrode Slurry by Mixer

贺亚雄 - 《《感光性电极浆料的制备与性能研究》》