Introduction of emulsion paint production process and production method

1. Pigment and filler feeding During the operation of the premixed pigment slurry, the feeding sequence of pigment and filler has a certain influence on the entire latex paint production process. No matter what kind of dispersion process it is, we hope to have a very uniform premixed slurry, that is to say, the pigment particles have been well wetted, which provides a good basis for the dispersion of the pigment.

For the premixing stage of the pigment, the following points are roughly summarized:

1) Before adding pigments and fillers, first add water (a part of water should be added), pigment dispersant and other additives into the stirring tank, stir well and then add pigments and fillers;

2) If you want to add a variety of pigments to your system, you should add the difficult-to-disperse pigments first, and then add the easy-to-disperse pigments;

3) If you want to add a variety of fillers to your system, put in the fillers with low density, high water absorption and fine particle size first, so when purchasing fillers, you must clarify the relevant indicators of each product;

4) The process of feeding must be carried out under the condition of stirring, and the powder is added to the vortex. The speed of feeding should be consistent with the speed of stirring as much as possible. In the process of feeding, we will find that it will generally cause agglomeration and wall attachment, so after each raw material is added, the residual material on the wall of the kettle should be scraped into the kettle and stirred. After feeding, use a part of water to effectively clean the inner wall of the kettle. Continue to stir for a period of time, and mix it well. When the pigment and filler are fully wetted, grind and disperse. However, for many small and medium-sized latex paint manufacturers, due to their own conditions, they generally seldom grind and disperse. Therefore, we recommend using low-speed stirring when adding pigments, and increasing the stirring speed after feeding, so that the pigments can be dispersed evenly.

2. Feeding of defoamer We all know that the addition of defoamer to latex paint is done twice. It is first added in the pre-mixing stage of the pigment, and then added in the let-down stage. The defoamers added in these two times can be the same one, but two kinds should be used for the selection and compounding effect. The anti-foaming effect is best added in the pre-mixing stage of the pigment slurry, because there are almost no bubbles in the system at this time, and its main function is to suppress the bubbles generated in the pre-mixing stage; the defoamer added in the let-down stage focuses on the defoaming performance , in order to effectively remove the foam that has been generated in the system, and at the same time suppress the bubbles generated during the let-down process. The generation and bursting of foam in latex paint system follow this rule: the smaller the viscosity of the system, the easier it is to generate foam, and at the same time, it is easier to burst the foam; on the contrary, the greater the viscosity of the system, the more difficult it is to generate and disappear the foam. Given this rule, we should pay attention to two points when we put defoamers:

1) Due to the high viscosity of the pigment slurry, anti-foaming defoaming agent should be added in the pre-mixing stage to make the system have as few bubbles as possible;

2) In the paint mixing stage, when the emulsion is added to the pigment slurry, the viscosity of the system will be reduced to the minimum quickly, so adding a defoamer at this time is the easiest way to eliminate foam.

3) For the thickening in the paint mixing stage, it needs to be carried out after the foam in the paint is basically eliminated, otherwise the foam after thickening is more difficult to eliminate.

3. In terms of feeding of film-forming aids In the production process of latex paint, film-forming aids can be selected in the paint let-down stage or in the pigment slurry premixing stage. If the polymer emulsion has good stability to the coalescent, it can be added after the emulsion is added in the let-down stage, or it can be added before the pigment is added in the premixing stage. If the stability of the emulsion to the film-forming aid is not good, flocculation and swelling are likely to occur, it should be added in the pre-mixing stage, so that the film-forming aid is diluted, and there will be no major problems when mixed with the emulsion. But in this case, part of the film-forming aid will be absorbed by the pigment, resulting in the "loss" of the film-forming aid. At this time, the amount of the film-forming aid will increase. Therefore, the compatibility of the coalescent and the emulsion greatly affects the performance and cost of the coating. Therefore, when using the coalescent, attention must be paid to the mixing stability of the two.

4. Thickener feeding Thickener plays a very important role in many latex paint systems. During the production process, most of the thickeners should be put into the premixing stage, because the dispersion of the pigment requires the premixed slurry to have a sufficiently high viscosity. Adding a thickener at this time, especially a thickener in powder form and a water-thickening type thickener, is also beneficial to the uniformity and stability of the latex paint. Thickeners are added during the letdown stage to adjust the viscosity of latex paint, and it is recommended to add them after all other raw materials have been added. Some types of thickeners need to be diluted with water or propylene glycol additives before adding to facilitate the stability of the system. The following mainly talks about powdered thickeners such as cellulose derivatives and natural polysaccharide thickeners. For this kind of thickener, it can be directly sieved into the kettle when used, or it can be made into a 2% aqueous solution and added. In general, adding it to the system in the form of a solution can reduce a series of problems such as clots and emulsion paint viscosity fluctuations caused by directly adding powder. Therefore, we suggest that the powdery thickener should be added to the latex paint in the form of an aqueous solution. The method of preparing the aqueous solution of the powder thickener is as follows: in the dissolving tank, first add the formula amount of water, start the low-speed stirring, and sieve the powder into the powder under the condition of stirring, adjust the pH value of the system to alkaline after a few minutes, The viscosity of the system rises immediately, at this time, you can increase the speed (the appropriate speed should make the liquid surface rotate smoothly), stir until the powder is completely dissolved, and the viscosity of the solution does not increase (about 10 minutes).

The following points should be paid attention to when preparing the solution:

1) It is necessary to use cold water to dissolve the thickener powder, because hot water will cause thermal degradation of cellulose, and the viscosity of the system will decrease during storage;

2) The cellulose powder needs to be slowly added to a non-alkaline solvent (water) to prevent agglomeration. After it is fully dispersed, add alkaline substances to adjust its pH value;

3) During the dissolution process, the stirring cannot be stopped. If the stirring is interrupted before the powder is fully dissolved, it may cause the thickener to agglomerate;

4) The solution prepared by the thickener is very easy to deteriorate during storage, so if it is stored, a certain amount of fungicide should be added.

5. In terms of latex paint mixing, those who are engaged in latex paint production know that the latex paint mixing stage is a very important part of the whole latex paint production project, which affects the quality of latex paint to a large extent. The paint mixing of latex paint is to mix the emulsion and related additives into the dispersed pigment slurry to prepare latex paint. In the production process of latex paint, the whole system is divided into two stages of pulping and paint mixing, because the polymer emulsion has stability problems when it participates in high-shear grinding. Because of this, it should be carried out at a low speed during the paint mixing stage. The success of the let-down process also depends on obtaining an intimate fusion of both the emulsion and the pigment dispersion, resulting in a stable and uniformly distributed suspension of all particles. Therefore, the paint mixing operation needs to pay attention to the pH value of the two dispersion systems of the emulsion and the pigment slurry, the presence of the electrolyte, the chargeability of the surfactant, the size, shape and distribution of the suspended particles, and other factors. The compatibility of aspects is very good, then the whole system is stable. During the production process we found that even with careful letdown operations, emulsions and pigment slurries would inevitably congeal slightly. For both, it may be important to preserve the polymer particles to the highest possible dispersion state. Therefore, in the process of letdown, a strict requirement is to add the polymer emulsion to the pigment dispersion. Usually, after adding emulsion to the pigment paste, the viscosity of the system will decrease, so a thickener is often added to increase the viscosity. We have found that thickeners with this function will more or less cause flocculation of the emulsion polymer particles, if this effect is excessive, it will cause the instability of the latex paint, resulting in cracking of the paint film and loss of adhesion wait. Therefore, when choosing a thickener, it is necessary to choose a thickening system that causes as little polymer agglomeration as possible. Of course, the production process of latex paint is a complicated process, so there will be problems of one kind or another in the production engineering. Therefore, as a paint producer or researcher, in addition to fully understanding the characteristics of the system, it is more important to clarify the role of each raw material in the system and the characteristics of the raw materials themselves. For this series of problems, only by being good at summarizing and analyzing in the long-term production process can the problems be solved fundamentally.

- 1Technical application of automatic Film Coater on latex paint

- 2Introduction of Working Principle and Application of Electric Oscillator Stirrer

- 3A Brief Discussion on the Difference between Disperser and Stirrer

- 4Common faults and solutions of Disperser Stirrer

- 5Explain the difference between Stirrer and Disperser

- 6Significance and method of latex paint gloss detection

- 7Application of Rotational Viscometer in testing latex paint viscosity

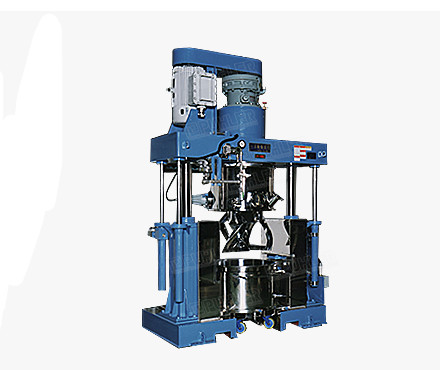

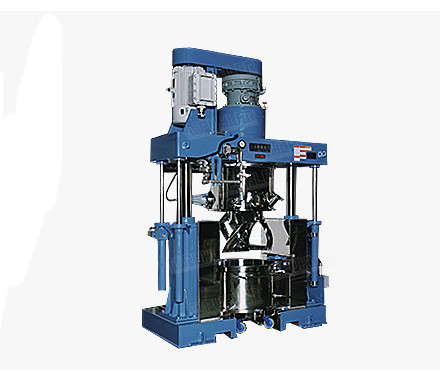

- 8Planetary mixer selection skills

- 9Features of acrylic latex paint