Application of ultra-fine coating powder

At present, the standard film thickness of powder coating is 60~80μm. For some products with low requirements, thick coating film is excessive in performance and increases the cost at the same time, which requires the development in the direction of thin film. For spraying factories that spray household appliances, due to the large amount of powder used, the use of ultra-thin powder spraying can effectively reduce the application cost of powder coatings (although the price of ultra-thin powder is higher than that of ordinary household appliance powder). At present, many home appliance powder coating factories such as Beijing Hisense refrigerator have successfully applied ultra-thin powder coatings. Ultra-thin powder coating can replace part of the paint, which is more environmentally friendly. Although the manufacturing cost is higher than that of ordinary powder, it reduces the cost of using powder coating. FLOWING1010, special additive.

Advantages of ultra-thin coating technology

1. The coating film is smoother and the orange peel is minimized;

2. The thickness of the sprayed film is 40-60μm, and the powder fluidization is very good during spraying, and there is no adverse disadvantages such as agglomeration and spit powder;

3. The coating film is denser, which obviously reduces the micro-bubbles in the coating film;

4. Reduce the cost of powder use and increase the area of powder spraying;

5. The appearance of the coating film is more beautiful, and it can be applied to occasions with higher decorative requirements.

Production technology and formula design precautions of ultra-fine thin coating powder coating

In order to reduce the cost reasonably, reduce the waste of raw materials and improve the production efficiency of ultra-fine thin coating powder coating to prevent caking in summer, this article provides several schemes for your reference:

1. The extrusion heat dissipation pipe can be installed with chilled water for heat dissipation, and the speed of the roller should not be too fast when pressing the tablet, just match the extruder to extrude;

2. When the weather is too hot to grind powder, a large amount of heat is generated in the mill due to the friction between powder particles. An air conditioner can be installed at the air inlet to cool it down to prevent agglomeration. The distance between the air conditioner and the air inlet is about 20 cm, so do not connect them closely, because the air delivered by the air conditioner is far from enough for the induced draft fan, and the air inlet is easily blocked;

3. After the powder is ground, immediately place it in an air-conditioned room to freeze, and place it on a clean floor, open the mouth of the bag to dissipate heat, and shake it at intervals;

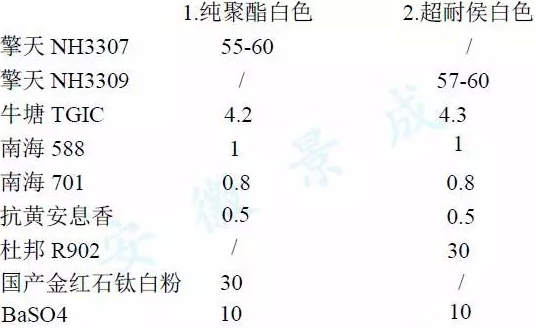

4. From the perspective of formula design, the selection of raw materials needs to be domestic familiar enterprises. Take the outdoor white formula for your reference:

5. Baking: 200°C/10 minutes.

Usually the thickness of ultra-thin powder coating is 40-60μm. Considering the hiding power, the ratio of titanium dioxide to pigment base should be improved, and the selection of raw materials is extremely strict compared with ordinary powder.

6. Production process:

The ingredient extrusion is the same as that of ordinary powder, the difference is that the ACM mill equipment manufacturer needs to make special modifications, and the particle size control of the powder is especially important. The particle size reference value: D10: 9-12μm, D50: 23-25μm, D90: 45-57 μm. The ultra-fine powder coating should be particle-free, and the rotating screen should be 250-mesh anti-static sieve or ultrasonic 250-mesh vibrating screen.

When applying ultra-fine coating powder, the particle size distribution, melt viscosity and gel time are the key factors to obtain a smooth coating film. However, it is difficult for ultrafine particles to break through the "Faraday cage" and reach the inner corner of the workpiece for powdering. FLOWING1010 overcomes the Faraday shielding effect significantly, improves the atomization and fluidity of the powder, enhances the electrification, and can be well sprayed into the inner corner of the groove. It is a good additive for the production of ultra-fine thin coating powder coatings.

- 1Nondestructive measurement Coating thickness

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 4Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- 5Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 6Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- 7Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 8Basic principle and application scenario of steel Coating Thickness Gauge

- 9Principle and Application Analysis of Coating Thickness Gauge