Printing ink performance - Fineness test

Performance indicators of ink products: used to characterize the performance indicators of ink products, if they are divided from the perspective of instrument testing, they can be divided into two types, one is qualitative indicators and the other is quantitative indicators.

1. Qualitative indicators

The purpose of the qualitative index test is to characterize the product, which needs to be judged by the use of the instrument, and the test has no numerical results. For example, the color of the ink, the anti-adhesiveness, the abrasion resistance of the ink after printing, and so on. Abrasion resistance can be tested by NMC-II abrasion resistance Tester. Its working principle is that the layer to be tested and the friction paper of the sample rub against each other at a specified speed under the action of a friction body with a certain load. According to the number of times of rubbing and the degree of wear, the performance of the ink against rubbing can be evaluated.

One of the most important indicators of ink, color is the most important thing for end customers. The color is roughly given by the pigment contained in the ink. Of course, the dispersion state of the binder and the pigment in the ink also has a certain influence on the color development of the pigment; the instrument for testing the color of the ink is currently used more in domestic enterprises. PM240-III flat Grinder.

2. Quantitative indicators

Quantitative indicators are to get specific values through the test of the instrument, so as to quantify the tested indicators. There are many such indicators, such as viscosity, gloss, dryness, fineness, and so on. There are many viscosity testing instruments and methods, and the standards adopted by various enterprises are different. The main instruments are flat-plate viscometer, rotational viscosity, and Laray (drop stick) viscometer. Gloss can be tested with a gloss meter. Among these indicators, there is an important indicator-fineness. Fineness is an important indicator directly related to the rheological properties and economic benefits of the ink. Inks with poor fineness can only be regarded as semi-finished products at most. The testing of other indicators of the ink can only be based on the finished ink that has passed the fineness. For the test of fineness, domestic enterprises mainly use scraper Fineness Meter at present.

There are many indicators for ink testing, and many instruments are used. The following will focus on the principle and test methods of the ink fineness test instrument-scraper Fineness Meter.

2. Determination of ink fineness

1. Definition of fineness: (Fineness)

The so-called fineness refers to the degree to which solid powdery substances such as pigments and fillers mixed in the linker are dispersed. It depends not only on the actual size of the individual particles, but also on how well they are dispersed.

2. Necessity of fineness test:

油墨的粗细度之所以是一个很重要的质量指标,因为它不仅与油墨的应用性能(包括着色力、色相、稳定性等)有关,还与油墨的流变性能以及经济效益有关。油墨太粗会引起堆墨、糊版等弊病,而且油墨的着色力、色相也都会变差;油墨太细,则流动性太大,在印刷后还会流动,这种流动会导致网点扩大,影响印品质量。另外,油墨的粗细还会影响其分散性。当油墨的分散性不称心时,它的印刷性能也不会令人满意,表现为印刷品表面不够光滑、流畅、柔和,而且会产生“块”状的感觉,因而大大降低了印刷效果。正因为如此,大多数油墨生产厂家都把细度作为重要的一个性能指标来对待。

3. 方法标准:

中华人民共和国化学工业部涂料专用器具检定规程JJG(化)018-96《刮板细度计》及其GB/T1724-93标准。

4. 测定的原理:

刮板细度计是一个在表面有凹槽或双凹槽的不锈钢平板,凹槽的深度由一端的最大变化至另一端的零值。放置试样,用刮刀在凹槽内刮成试样薄膜,从薄膜中产生的线条来测定试样粒子的大小。在平板上标注出凹槽对应深度,以读出被测量颗粒的大小。

5. 刮板细度计的组成及精度控制:

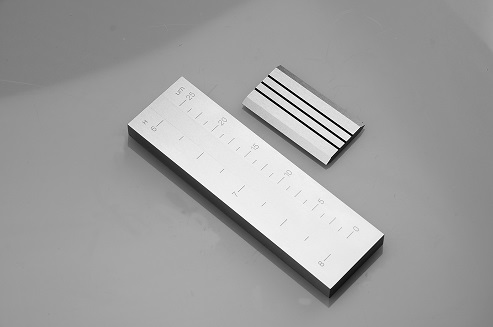

图(1)刮板细度计外形图

如图(1)所示,刮板细度计是由刮板和刮刀两部分组成的。

刮板的主要尺寸如图(1)所示。刮板的材料应是工具合金钢,例如性能优异的4Cr13型锻打件。板上有一凹槽,在凹槽边上标注出凹槽对应深度,以读出被测量颗粒的大小。 表面光洁度应为▽10,凹槽光洁度为▽10。这里需要提出的是目前油墨行业内大多是用0-25μm双凹槽的刮板细度计,这是因为油墨产品对细度的要求大多数都在15μm以下,且双槽可以使测试的数据更加准确,减少了人为误差,下文还将有详细分析。

由于油墨厂家对细度要求越来越高,本公司特提供0-15um刮板及大尺寸的油墨行业专用刮板。

②刮板精度的控制:

a.刮板细度计上平面平直度0.003毫米。

b.凹槽底平面平直度0.003毫米。

c.分度值误差0.001毫米。

The scraper Fineness Meter is verified by an optical comparator, but the user of the scraper Fineness Meter does not have an optical comparator, so it is generally only the manufacturer's factory inspection. Check the flatness of the plane on the scraper at two points. Take the plane of a certain micron scale line as 0, measure the groove depth of this point; then take the plane of another micron scale line as 0, measure the groove depth of another point, and so on. There are two points to note:

(1) Whether the number of microns on the reference plane of any micron scale line is 0, in short, are the two sides of the groove of the scraper fineness gauge flat? For the manufacturer, it is generally said how to grind out the plane to ensure that the plane error is within a certain amount, which will lead the user into a misunderstanding. There is an easy way to overcome it. Using the method introduced above, scrape the adjusted ink from top to bottom with a qualified scraper. If the two sides can be scraped clean without ink, the surface can generally be considered as a plane; if the surface adjacent to the edge of the groove is scraped It can be scraped clean, and the position farther away from the surface of the groove can not be scraped clean, and it is judged as medium high; otherwise, it is medium concave. If there are patterns on both sides of the groove after scraping, it means that the upper surface of the scraper is not flat.

(2) Assuming that the upper surface of the scraper is flat and the flatness of the bottom of the chute is 0.003mm, for ink workers, the acceptable error of the flatness of the flatness of the scraper or the flatness of the bottom of the chute can only be ≤±1μm. Except for the middle groove, the satisfactory scraper Fineness Meter has the entire surface of the scraper as a plane, the zero point is aligned, and the error between the groove depth of each point and the marked value does not exceed ±1μm.

Ⅱ. Scraper

① The main dimensions of the scraper are shown in Figure (1). It is made of good tool carbon steel, both edges are ground, the surface finish should be ▽8, and the edge grinding finish is ▽10.

②Control of scraper accuracy: The straightness of the two blades of the scraper is 0.002mm. In order to achieve the flatness index of the scraper, some manufacturers grind the blade into a small plane perpendicular to the blade. Here the author proposes based on experience: Although the straightness of this kind of knife reaches the target, it can only scrape ink when the knife edge is completely vertical in the test, and other angles are not applicable. In severe cases, the ink on the planes on both sides of the groove cannot be scraped at all. A "full house" scraper. Accurate detection results cannot be obtained using this scraper. The ink scraping by the scraper should be scraped off by holding the knife vertically, which is only vertical by visual inspection. There is always a certain error in the specific operation. The edge of the satisfactory scraper is ground into a 15-degree arc to avoid this error. Generally speaking, the smaller the arc, the sharper the knife, the lower the fineness (fineness) of scraping, and vice versa . Therefore, a radian of 0.2mm should be ground on the edge of the knife during grinding.

Ⅲ. Error discussion and solution.

油墨行业对刮板细度计准确度要求甚高,而刮板和刮刀在实际使用中均可能会引起测量误差,为了能得到准确的检测结果,我们可以采用以下两种方案解决这一难题。

①匹配法:

微米数偏高的刮板与弧度偏小的刮刀匹配。 微米数偏低的刮板与弧度偏大的刮刀匹配。匹配后的刮板细度计与公司质检中心在国家计量检定所检定的刮板细度计对比校正,如果不合适更换刮刀或刮板直至合适为止。

②研磨刮刀法:

如具备磨刮刀技术,可通过磨刮刀使对比的刮板细度计与标准刮板细度计细度值基本相同。

6.细度测试方法:

① 工具与材料:

a.调墨刀:木柄锥形钢身,长200mm,最宽处20mm,最窄处8mm。 调墨刀平面应光滑,更好用压延抛光的,粗糙的刀表面会存留油墨,另外刀口更好磨成与刀平面成30~40度角,平直度较好,这样的刀口才能在玻璃板上刮净油墨,每次擦时才能擦净。

b.玻璃板:200mm×200mm×5mm

c.乙醇:工业用

d.洁净棉纱。

②测试条件:

测试应在温度(25±1)℃和(65±5)%相对湿度下进行。

③测试步骤:

a.取适量的油墨,置于玻璃板上,用调墨刀将其调匀。

b.将调和均匀的油墨置于刮板细度仪上的凹槽深处,将刮刀垂直横置于刮板仪凹槽深处的油墨上,刮刀保持垂直,然后用双手的拇指和重指握住刮刀,用4秒以上的时间,向0刻度方向均匀刮动。

c.刮好后,立即将刮板仪表面以30度角斜对光源,观察油墨在两槽上呈现的划痕迹数以及其对应的刻度数值。这里笔者就要说明一下采用双凹槽的细度计的优点了,由于细度板的测试是手工操作,观察出数据,因此受人为操作误差较大,不同的人可能测出的数据有偏差,如果象传统的涂料行业测细度时采用单凹槽的细度计,得出得数据更没有可比性。而双凹槽测试结束后,如果发现两条凹槽的数据相差一个刻度时,试验需要重做,这样就减小了人为误差对测试结果的影响。

7.测试的一些注意要点。

During the detection process, due to factors such as instrument errors, human operation errors, and similarities and differences in environmental conditions, there are often disputes between the production control center and the company-level quality value center, and between the company-level quality inspection center and the printing factory when testing ink fineness. . Therefore, as an ink manufacturer, the influence of these external factors on the test results should be minimized. The following is the author's experience based on some common factors and solutions that affect the results, for readers' reference.

① Take ink sample:

The surface layer of offset printing ink is conjunctival due to oxidation. When taking ink, the dry skin on the surface should be removed first, and the ink at four positions should be taken to make it representative. Move the ink taken on the glass plate 15 times, one round trip. Take a small part of it, such as 0.3ml for each use.

② How to use the scraper:

When scraping ink, the scraper should be as vertical as possible. The fineness value obtained by tilting the knife backward is smaller (fine), and the fineness value obtained by tilting forward is larger (coarse). When scraping the ink, use the knife with both hands evenly, not focusing on one side.

③Observation method: Immediately after scraping the ink, observe the surface of the scraper instrument obliquely to the light source at an angle of 30 degrees, and quickly determine the concentration point and the number of particles within a scale range on the concentration point within 30 seconds to determine the fineness value. Fast and accurate. The light source for observing the fineness is better to be a standard light source. If the conditions are not available, the brightness of the light source should be appropriate, and a magnifying glass should be used to assist observation.

④Priority test to ensure fineness: For an ink, if the item to be measured is not one item, then measure the fineness first, so as not to pollute the ink when testing other items. Measure the fineness, scrape the color chip and measure the tinting strength, and then do other projects.

⑤ Guarantee the test environment: The environment for fineness testing should be kept free of flying dust, cotton yarn and other auxiliary materials should be prepared in advance, and the solvent should be filtered well. The ambient temperature should not be too low. It is not appropriate to say that the detection fineness has nothing to do with temperature and humidity. It is better to test under standard temperature and humidity conditions.

At present, the quality of domestic scraper Fineness Meters in the market is uneven, and the price of imported scraper Fineness Meters is very expensive. Pushen company is currently launching a full series of scraper Fineness Meters with high precision and economical prices. It promises to pass SIMT Shanghai Metrology Institute And SGS general standard company measurement certification.

- 1Coating fineness test method and influencing factors

- 2Detection Steps of Coating Fineness and Operation Method of Ground Gauge

- 3Coating fineness measurement and its role in Coating quality control

- 4Enamel paste fineness requirements

- 5Performance subjects that must be inspected in the production process of water-based wood coatings? What are the indicators?

- 6These properties of water-based alkyd resin coatings need to be tested? Tell you how to reach the standard?

- 7What performance subjects should standard coil coatings test? What are the technical indicators?

- 8What properties should solvent-based polyurethane coatings be tested for, and how can they be considered up to standard?

- 9What subjects are generally tested for architectural paint color paste?