Film thickness measurement method _Defelsko comparison of several different Thickness Gauges

This article details the use of DeFelsko's coating Thickness Gauges in the galvanizing industry. It describes the different types of handheld instruments, some precautions to take during measurements, and frequently asked questions about the application in the Q&A section.

background

To avoid rust, it is necessary to prevent the formation of corroded cells. Two common methods for corrosion protection of steel:

Catholic protection (using sacrificial anode). Create a barrier that blocks the electrolyte from contacting the steel.

galvanized

galvanized

● Uniformity

● Service life

● Number of corrosion protection

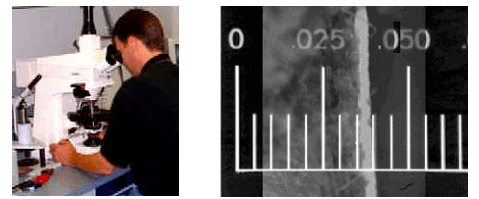

Magnetic principle Thickness Gauge Strip and weigh Weighing part before and after galvanizing Optical microscope( ASTM B487 )

non-destructive simple, fast and cheap Meets internationally recognized standards including ASTM d7091

, CSA G164M and ISO 2808

Because it is non-destructive, Magnetic thickness measurement

Galvanized layer thickness is a commonly used method for evaluation.

Magnetic principle Thickness Gauge

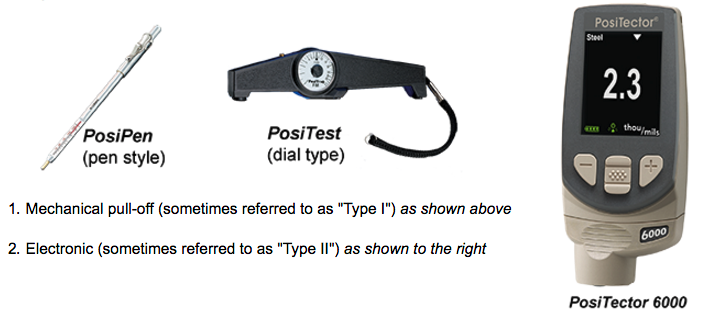

Compare Magnetic Thickness Gauge Types

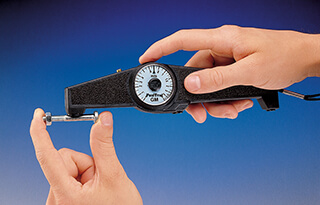

mechanical meter

Measure the strength needed to pull the steel away from the magnet. Thicker zinc, weaker magnetic attraction. No calibration adjustment required simple and sturdy electronic meter

测量使用电子电路的磁通密度的变化。 显然,数字读出 专门探讨风格多种多样 许多提供内置存储器 可以作出调整基板条件

磁力计的特点

机械/笔式

●无需校准调整

●很小,独特的磁铁允许精确位置

●适用于小的,热的,或很难获得的测量位置

●±10%精度

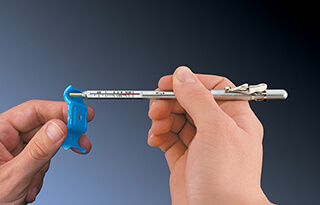

机械/类型

●无需校准调整

●简单,耐用,普遍接受的

●没有电池/电子

●go/no-go按钮可预置的快速测量

●±5%精度

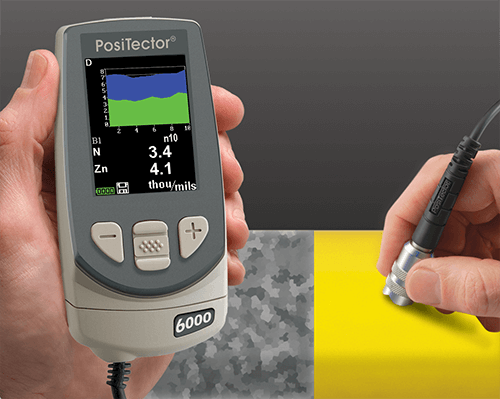

电子

● 快速和简单的操作

● 手动校准调整提高精度是可能的

● 易于阅读的数字显示

● 灵活的积分或各种有线探头

● 连接选项,直接打印,USB,WIFI,蓝牙

● 统计能力平均,最小/最大

上报测量数据的功能强大的软件 内置存储器 ±1%精度

注意事项:

按照制造商的指示计 定期验证使用精度

确保测试表面无灰尘、油脂、氧化和腐蚀产物 测量点选择应尽量避免在涂层明显的峰值或违规 阅读足够数量可得到真正的平均涂层厚度

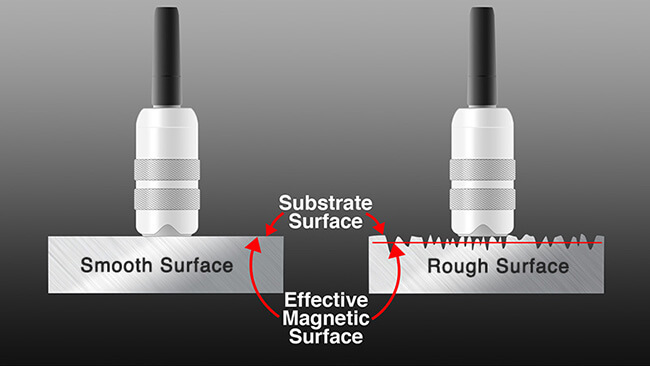

为了弥补基质条件的影响(包括质量、冶金、粗糙度、温度和曲率),测量涂层基板/部分在一些点,获得有代表性的平均值。这个平均值称为“基础金属读数”或“BMR”。 测量在通过相关程序或标准要求的景点数量的锌层厚度。 减去基础金属读数(BMR)从读数获得的镀锌层厚度。

为了弥补基质条件的影响(包括质量、冶金、粗糙度、温度和曲率),检查零未涂覆的基材/部分调整如果有必要的话 。 通过测量垫片放在未涂覆的基材检查。 测量镀锌部分。仪表读数表明应用镀锌厚度。

双涂层系统的测量

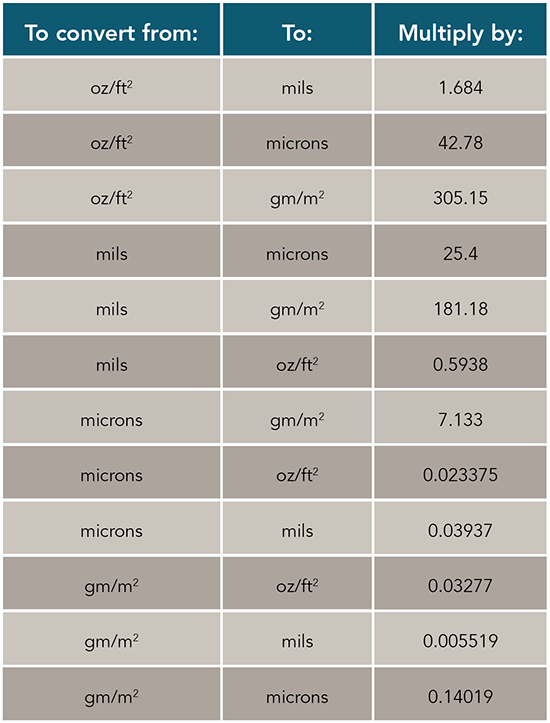

例如转换

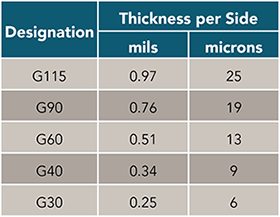

将0.35毫升的读数2占面板的两侧(0.70毫升) 0.70乘以0.5938的系数转换成盎司/英尺²(0.4157盎司/平方英尺²) 0.4157盎司/平方英尺²锌镀锌表明G40重量(0.40盎司/平方英尺²最小平均,ASTM A 653 )

0.45 oz/ft² x 1.684 = 0.76 mils per side, or 0.45 oz/ft² x 42.78 = 19 μm per side

问答

A、虽然镀锌表面可能光滑,但锌和钢表面都存在微观表面粗糙度。因此,涂层厚度很好的表示是由一系列的读数平均每ASTM A123获得。

A: Magnetic coating Thickness Gauges measure measurements in units of linear distance, not coating weight. However, a code reader can easily be converted to an expression for coat weight through a conversion table or multiplication factor.

A: According to

0.45 oz/ sqft x 1.684 = 0.76 mils/part0.45 oz/ sqft x 42.78 = 19 μm /section

ASTM standard

The coating thickness of the test specimen shall be averaged over a minimum of 5 readings at widely dispersed points. This average value shall not be less than the value in the specification table below the coating thickness class. The thickness should be between 1.4 and 3.9 ml (35 and 100 µm) depending on the paint grade.

- 1Defelsko PosiTector 200 Ultrasonic coating Thickness Gauge Chinese version Instructions for use [2023 new version]

Defelsko

- 2Defelsko PosiTector 6000 coating Thickness Gauge Chinese version Instructions for use [2023 new version]

Defelsko

- 3Cast Iron Wall Thickness Measurement with Defelsko PosiTector UTG Thickness Gauge

- 4How to measure the thickness of plastic bottles with an ultrasonic Thickness Gauge?

- 5Tide Review: Coating Thickness Gauge PosiTector 6000 FS1

- 6Erosion and Corrosion Coating Thickness Testing of Defelsko Coating Thickness Gauge Solutions

- 7The new version of the Defelsko host is coming, and the North-South Tide will take you to see it as soon as possible!

- 8Defelsko Calibration, Validation and Adjustment

- 9Measuring the thickness of sprayed truck backing