Destructiveness measurement coated Film thickness

Coating Thickness Measuring Principle

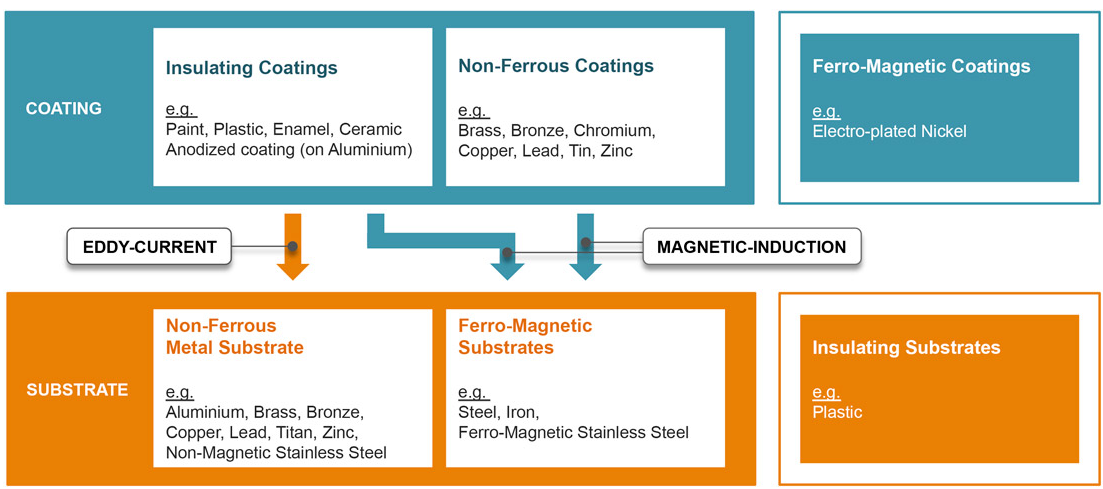

Coatings and parts are coated with a coating for decorative and surface protection purposes, and the actual measurement of coating thickness for the applied material is very important. Phynix coating Thickness Gauges use two different methods for non-destructive thickness measurement: magnetic induction and eddy current principles:

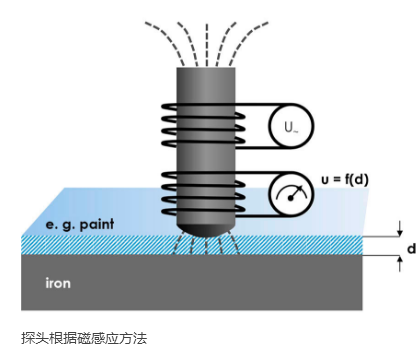

For the non-destructive measurement of ferrous materials, i.e. ferromagnetic substrates, the principle of magnetic induction is used. The principle of magnetic induction is in models marked with F or FN (F = ferromagnetic) such as the suffix ®FN. Coatings need to be non-magnetic such as varnish, paint, enamel, plastic, glass, aluminum, lead, chrome, copper, brass, zinc, tin, etc.

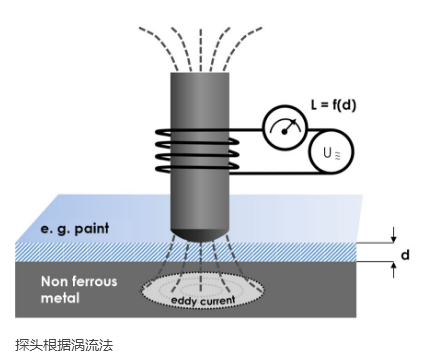

The eddy current principle enables non-destructive measurements on non-magnetic metal substrates such as aluminum, aluminum alloys, lead, bronze, copper, brass, zinc, die-cast zinc, tin. The eddy current principle is used for marking or FN models (n = colored), such as the suffix ® easy i-fn. The coatings tested need to be electrically insulating, such as varnishes, paints, enamels, plastics, glass, anodized coatings and ceramics.

Typical applications for coating Thickness Gauges use magnetic induction and eddy current principles

Method 1: ISO 2808 Magnetic induction method: DIN EN ISO 2178, ASTM b499, ASTM open D7091 Eddy current method: DIN EN ISO 2360, ASTM d7091 Basic terms of measurement technology: DIN 1319, Part 1 and Part 3

functional sensor

- 1Nondestructive measurement Coating thickness

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 4Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- 5Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 6Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- 7Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 8Basic principle and application scenario of steel Coating Thickness Gauge

- 9Principle and Application Analysis of Coating Thickness Gauge