Will the environment temperature cause errors in flaw detection?

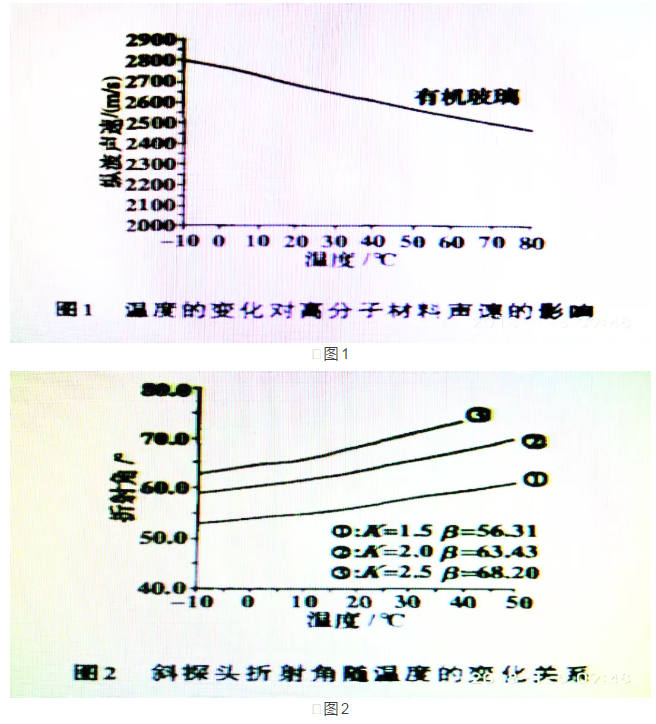

The probe used in ultrasonic detection is made of plexiglass as a wedge. The sound velocity in plexiglass decreases with the increase of temperature, and the change of sound velocity will inevitably cause the change of the refraction angle (transverse wave) of the incident sound wave in the workpiece, which will eventually affect the defect location. .

It can be seen from Figure 1 that when the temperature of the plexiglass is 20 degrees, its sound velocity (longitudinal wave) is CL1 2730m/s; when it is 40 degrees, it is CL2 2650m/s.

When the steel plate temperature is 20 degrees, its sound velocity (transverse slope) is CS1 3230m/s; when it is 40 degrees, it is CS2 3222m/s.

In this case, assuming that the object to be detected is at room temperature, a probe with a K value of 2 is selected, the incident angle α is 49.9 degrees, and the refraction angle β1 is 63.4 degrees.

When the temperature rises to 40 degrees, it is calculated according to the law of refraction:

β2 = arcsin (CS2/CL2sinα)

=arcsin(3222/2650sin49.1)

=66.9 degrees.

Then substitute into the following calculation: K=tg66.9=2.34.

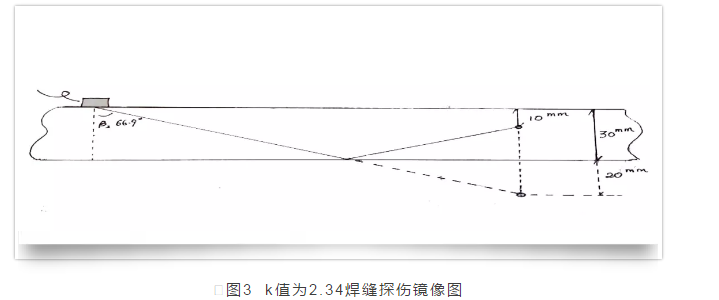

It is known from the calculation that as the temperature of the workpiece increases, the shear wave refraction angle in the workpiece has changed from 63.4 degrees at room temperature to 66.9 degrees, and the K2 probe at this time is actually a probe with K=2.34.

When the ambient temperature is 40 degrees, when we use the K2 probe to find defects, it is actually equal to the k2.34 probe.

When the second reflection method is used to find that the actual depth of a defect is 10mm, that is, when the sound wave travels 50mm deep, the sound path is S=50/cos66.9=127.55mm.

At this time, the fluorescent screen of the instrument displays the depth calculated by the sound path k2 probe.

That is, h=S*cos63.4=57.1mm, so that the flaw detection depth is 2T-57=3mm, which is 7mm less than the actual depth of the flaw, so that the welder did not plan the flaw.

In order to accurately locate the defect, the change of the probe k value with the change of the ambient temperature cannot be ignored, and the k value increases with the increase of the ambient temperature.

From Figure 2 we know that the larger the k value is, the faster the refraction angle will increase as the ambient temperature rises.

Therefore, in the actual flaw detection, it is necessary to adjust the equipment according to the site conditions when the probe test block and the ambient temperature are balanced. If necessary, the test block can be brought to the site environment to debug the equipment, and the k value and sound velocity can be accurately measured, thereby improving the positioning accuracy. Reduce misjudgments and missed judgments and some unnecessary losses.

- 1Basic Principle Characteristics and Application Analysis of Flaw Detector for Casting

- 2The working principle and application of eddy current Flaw Detector

- 3Application of Ultrasonic Flaw Detector in Weld Flaw Detection

- 4Ultrasonic flaw detection defect judgment

珀泰@sisi

- 5Ultrasonic flaw detection FAQ answer summary