Analysis of the Method of Detecting Steel Castings with Ultrasonic Flaw Detector

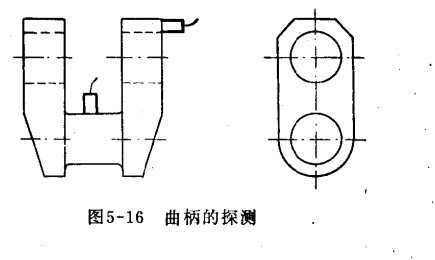

(1) For flaw detection of cast steel cranks, use a straight probe of an ultrasonic flaw Detector (generally 2.5 MHz) to conduct a comprehensive detection on the plane of the journal pin and fan plate with a pulse reflection method, as shown in the figure below. If necessary, an oblique probe can be used on the journal to detect cracks in the shaft.

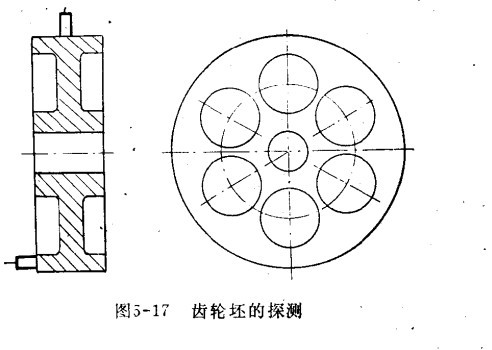

(2) For the flaw detection of the gear blank, use a straight probe (generally 2.5 MHz) to detect flaws on both ends of the gear ring after heat treatment. As shown in the figure below, first use the multiple pulse reflection method to detect whether there are defects. A pulse reflection method is used to measure the position and distribution range of defects on the outer circle of the gear.

(3) Flaw detection of steel casting blanks Steel casting blanks (natural surface) can be detected by the water glass surface hardening method (or water immersion method). This method is to remove the surface of the steel casting first, and then apply water glass on the surface of the steel casting. If there are small holes on the surface of the steel casting, it should be coated with dilute water glass first, and then use water glass with higher viscosity. Cover the surface, wait until it dries to form a hard and smooth artificial surface, then use oil as a coupling agent (not water), and use a straight probe or an angled probe to detect. Water glass is alkaline and has a corrosive effect on metal and skin, so care should be taken when using it.

- 1Application of Ultrasonic Flaw Detector

- 2Ultrasonic Flaw Detectors: the right-hand man for nondestructive detection

- 3The role and application of ultrasonic flaw Detector

- 4What is an ultrasonic flaw Detector?

- 5What is an ultrasonic pulse echo system?

- 6Application of Ultrasonic Flaw Detector in Weld Flaw Detection

- 7Method for calibrating ultrasonic straight probe, dual crystal probe and oblique probe

- 8Detailed explanation of commonly used ultrasonic flaw detection methods

- 9Application of Ultrasonic Nondestructive Testing in Steel Structure Identification and Testing