Powder coated Film thickness measurement - steel, aluminum, wood

DeFelsko manufactures instruments that can measure the thickness of powder coatings on a variety of substrates before or after curing. This article describes measurement solutions and lists the corresponding ASTM test documents.

Brief introduction

Thickness measurement of the powder can be done before and after curing. The type of substrate, the range of thicknesses, the shape of the part and the economy determine how well it can be used.

For uncured powders, height measurements can be performed using a powder comb and a magnetometer using a special powder probe. These techniques are destructive and may require repainting of parts. The thickness of the coating powder typically decreases during the curing process, so these procedures require the determination of a shrinkage factor to predict the thickness of the cured film.

The ultrasonic instrument can also measure uncured powders without touching the surface. Instead of measuring the powder height, they automatically display the predicted cure thickness results.

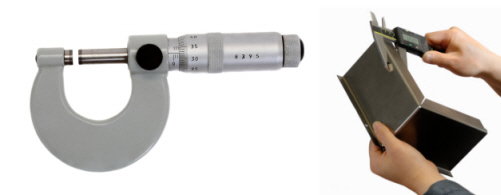

For post-curing measurements, a variety of handheld instruments can be used. These non-destructive instruments employ magnetic, eddy current, or ultrasonic principles depending on the substrate. Less common methods include micrometer measurements, destructive dry film methods such as cross-sectional and gravimetric (mass) measurements.

After the measurement

We start with a discussion of post-cure measurements, simply because cure thickness targets are the most frequently provided values by powder manufacturers and coating specifiers. Dry Film Thickness (DFT) instruments are versatile, affordable, non-destructive, and easy to operate. They employ magnetic, eddy current, or ultrasonic principles depending on the substrate.

Three operating principles are adopted. The magnetic principle is used to measure non-magnetic coatings on steel parts. For other metals, if the coating is not electrically conductive, the eddy current principle is used. For non-metals, the ultrasonic principle is used.

Magnetometer – mechanical

When a part is made of steel, a mechanical or electronic operation is used for magnetic thickness measurement.

Mechanical tension strain gauges use permanent magnets. The curing thickness is determined by measuring the force required to pull the magnet from the surface of the coated steel. Magnetic pull-off gauges are robust, simple, inexpensive, portable, and usually do not require any calibration adjustments. They are a good low-cost alternative where quality targets only require a small number of readings during the production process.

DeFelsko manufactures two types of mechanical instruments. The PosiTest FM is a pullback model consisting of a magnet attached to one end of the pivoting balance arm and connected to a calibrated hairspring. By rotating the dial with your fingers, the spring increases the force on the magnet and pulls it off the surface. Safe for use in explosive atmospheres, typically used by paint contractors and small powder coating operations. It has a tolerance of ±5%.

PosiTest FM

posipen

Electronic instruments

A variety of electronic instruments can be used to measure metal parts. The magnetic principle is used for the measurement of steel, and the eddy current principle is used for aluminum. The measurement results are displayed on an easy-to-read liquid crystal display (LCD). Typical tolerances are between ±1 and 3%.

Our basic electronic solution is called PosiTest DFT. Two models are available, each with a measurement range of up to 1000 microns (40 mils). The PosiTest DFT Ferrous model is recommended for steel substrates, while the PosiTest DFT Combo model is suitable for measurements of all metal substrates.

Non-magnetic measurements

positector 6000

Coatings for non-metallic substrates

Magnetic and eddy current instruments measure metal powders. Non-metallic applications such as coated plastics and wood require ultrasonic pulse-echo technology.

Ultrasonic testing works by using a probe (transducer) to send ultrasonic vibrations into the coating with the assistance of a gel (or water droplet) that is temporarily applied to the surface.

This relatively recent advancement has enabled industry to perform non-destructive quality control at a reasonable price. The benefit of this measurement technique is that it is possible to measure individual layers in a multi-layer coating system.

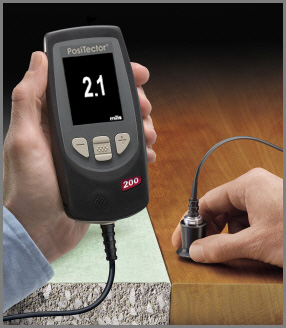

Our ultrasonic PosiTector 200 B Std is ideal for measuring the thickness of powder coatings applied to non-metallic substrates. It has a range of 13 to 1000 microns (0.5 to 40 mils). ASTM D6132 describes this test.

positector 200 B standard

Other methods

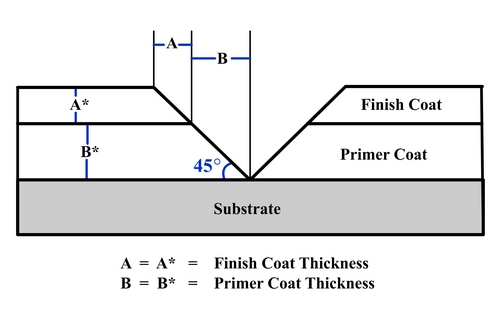

Cut through a V-groove with a two-layer coating system

Transverse section

Measured before treatment

Dry powder coating measurements

Although most powder coating specifications give a cure thickness target, it is possible to determine if the powder applied prior to the end point of curing and crosslinking is within the thickness specification.

There are good reasons to want to accurately predict the curing thickness, especially on a mobile production line. Depending on the length of the oven, i.e. the number of parts cured, the time required for the curing process and the time required to manually measure the film thickness after curing, there is a considerable delay before the operator intervenes in the application to make any necessary changes.

If coating defects are found, a significant number of coated parts need to be reworked in the repair ring, or may even need to be scrapped if reprocessing proves too expensive. For some operations, these shortcomings no longer meet the requirements of modern finishing processes.

Measuring powders in a pre-cured, pre-gel state helps ensure the correct cured film thickness. It allows the application system to be set up and fine-tuned prior to curing. This, in turn, will reduce the amount of scrap and over-spraying. Accurate predictions help avoid peeling and recoating, which can lead to bonding and coating integrity issues.

ASTM's Test Procedures

ASTM D7378 describes three measurement methods for the thickness of pre-applied cured coating powders used to predict cure thickness.

A. Rigid metal notched (comb) gauge.

B. Electronic coating meter with a special powder probe.

C. Non-contact ultrasonic instrument.

Procedure A uses an inexpensive DeFelsko powder comb, which works in the same way as a wet film meter. The comb is dragged over the uncured powder, and the powder height is considered to be the range value between the highest numbered tooth to which the mark was made and to which the powder was attached and the next highest tooth to which no marks were left and no powder was attached.

These gages are relatively inexpensive and have an accuracy of ±5μm. A variety of powder comb models are available to measure from 75 to 1250 microns (3 to 50 mils) on any substrate. They are only suitable as a guide, as post-flow curing films may be different. Traces left by gages may affect the properties of the cured film.

Powder comb

Procedure B uses a conventional magnetic or eddy current coating Thickness Gauge, but uses a specially designed powder probe to measure the thickness of the coated powder. Three miniature pins integrated into the probe penetrate the coating powder down to the substrate. The probe is manually pressed down to the surface of the powder for height measurement. This procedure is only suitable for metal substrates. Markers can be made from powders that may not be covered as they flow during the curing process.

Procedure A and Procedure B only result in the height measurement of the uncured paint powder. However, thickness specifications are usually expressed in terms of the thickness of the cured powder. Since the thickness of the coating powder typically decreases during the curing process, both methods require the establishment of a reduction factor to predict the cured film thickness for each specific coating powder.

This reduction factor is obtained by measuring the thickness of the solidified powder at the same location as the uncured powder thickness measurement. For good accuracy, different thicknesses should be measured before and after curing.

An example plot of the measurement results is shown here. From this figure, the reduction factor can be identified and applied to all future dry coat powder thickness measurements to predict the cure thickness.

Typical relevance: pre- and post-curing powders

Procedure C of ASTM D7378 describes a relatively new instrument, the PosiTector PC Powder Detector. This is an ultrasonic device that can be used non-destructively on uncured powders to predict the thickness of the cured film.

The powder checker is handheld, battery-powered, and can be used outside of the box for most powders. Its simple operation and rugged design allow it to be used quickly and efficiently by line operators.

Non-contact coating thickness instruments have the advantage of being non-destructive. This means that after the measurement, the measured part can be reintroduced into the process without being damaged.

To operate, press the probe button and hold it about 18 mm (0.75 in) away from the part for 2 to 5 seconds. The predicted cure thickness results appear immediately on the probe and base display.

appendix

Units of measurement

Background of powder coating

Powder coatings are still the fastest-growing of all finishing technologies. It is an attractive paint, like a protective paint, that is long-lasting and highly resistant to chips, scratches, and fading. It offers a seamless coating from an almost unlimited selection of colors, textures, and finishes.

Powder coating is a cost-effective, one-step method that does not require continuous coating and long curing times. The powder particles used are a mixture of finely ground pigment and resin particles. The charged powder particles are transferred to the electrically grounded surface. There are a variety of processes for powder applications. These applications range from electrostatic spraying for thinner coatings (0.001" - 0.010") to impregnation in fluidized beds for thicker coatings (0.007" - 0.040").

During the curing process, the powder fuses into a smooth coating. Depending on the process, powders can be thermally cured (convection or infrared) or UV cured. The powders used can be thermoplastic (the same chemical composition after reflow) or thermoset (chemically cross-linked with themselves or other reactive components).

Powder coating has been used on metal surfaces for over 40 years. Recent advances have been extended to ceramic, plastic (nylon and polycarbonate) and MDF (medium density fiberboard) applications. Research is underway to expand the use of powder coatings to include substrates such as hardwood, laminate flooring, and particleboard.

UV curing

Unlike heat-curing powders, UV-curable powders separate the melting and film-forming stages from the final curing stage. Short-wave infrared and convection heating allow the melting process to use relatively low temperatures. The result is lower temperature curing and improved flowability. The wavelength and time required for UV curing depends on the color and expected film thickness. Coating thicknesses can range from 20 to 100 microns (1 to 4 mils). An important challenge with UV curing is the cost of current powders and the need to position UV light to ensure 100% coverage.

Since UV curing does not require high-temperature curing, significant reductions can be obtained in the space required, on conveyors, and on shelves during the cooling process. Unlike heat, UV provides an instantaneous cure, significantly increasing throughput. The process savings are significant due to the reduction in energy and equipment required for heating. UV powders are also easy to clean and recycle, while providing a VOC-free process.

The available market is expanding due to lower process temperatures, which allow heat-sensitive substrates such as MDF and plastics to be powder-coated. The use of UV curing also significantly reduces the cost of powder coating for high-mass components used as heat-curing radiators, such as engine blocks.

Why measure thickness?

The coating is designed to better perform its intended function when applied within the strict thickness range specified by the manufacturer. This ensures very good product performance. Many of the physical and cosmetic properties of the finished coating are affected by the thickness of the film. Film thickness affects the color, gloss, surface profile, adhesion, flexibility, impact resistance and hardness of the coating. When the coating thickness is not within tolerance, the assembled parts after coating may be affected. As a result, coatings need to be applied within specific minimum and maximum film thickness specifications to optimize their intended use.

When insufficient powder coating is applied, it does not provide adequate coverage and protection. For example, metals require sufficient coating thickness to prevent environmental influences such as corrosion (steel) or oxide (aluminum). In addition, improper powder coating thickness can lead to a poor surface finish and undesirable appearance or color.

Powder coating thickness may also affect an application's impact resistance, flexibility, hardness, edge coverage, chipping resistance, weather resistance, salt spray resistance, and ability to maintain gloss. The manufacturer provides a production specification sheet for powder-coated materials. Powder coaters attempt to apply a uniform coating that meets specifications. Powder coating measurements enable the coater to adjust its coating process to specifications.

For example, on medium-density fiberboard (MDF), powder coatings are typically between 1 and 8 mils (25 to 200 microns) or more for thermoplastic coatings. Typically in the thicker density range, the surface coating is more durable. Factory specifications typically require a specified ±1 mil tolerance. This level of quality cannot be determined by observation alone.

There are other benefits to accurately measuring surface thickness in accordance with ISO, quality and customer requirements for process control or cost control. When companies fail to inspect and confirm the coating quality of incoming materials, they waste money on reworking products. By inspecting their application equipment, they ensure that the coating meets the manufacturer's recommendations. Applying too much film thickness has the potential to result in incomplete curing and can significantly reduce overall efficiency. Too much powder coating can lead to poor adhesion and tend to peel or chip from the substrate. Regular testing can reduce the number of internal rework and customer returns due to completion defects.

Affordable

High-tech quality control equipment can help companies maximize paint usage and improve their bottom line. In the past, expensive and complex color and thickness testing equipment was mainly for large companies with larger budgets. However, over the past few years, the price of quality control test equipment has continued to advance in technology and the price has decreased, making sourcing equipment more practical and affordable for small companies on a tight budget.

Technological advancements have been key to the growing popularity of thickness testing equipment. These improvements have helped manufacturers produce smaller, more portable, rugged, and simple-to-use devices. The price of Thickness Gauges is also declining, as the materials used to produce them are more abundant. Mass production of the same materials used in mobile phones, PDAs and computers.

Summary of ASTM tests

The measurement of powder coating thickness can be done using different methods, depending on the substrate and whether the test is performed before or after the powder has cured. ASTM has a series of documents describing these technologies.

Practice D7378 describes three measurement methods for the thickness of pre-applied cured paint powders used to predict cure thickness.

Test Method D 4138 describes the destructive measurement of rigid substrates manufactured with cross-sectional instruments.

Practice D 7091 describes the non-destructive measurement of metal matrices made with magnetic and eddy current coating Thickness Gauges.

Test Method D 6132 describes the non-destructive measurement of non-metallic substrates fabricated with an ultrasonic coating Thickness Gauge.

- 1Determination of thermal plasticity Resin melt flow rate

- 2Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 3Density Determination Method and Application

- 4Determination method of cone-plate viscometer and its application

- 5Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 6Determination of compatibility of powder coatings: methods, effects and applications

- 7Evaluation of flowability of powder coatings: key factors and significance

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Importance of powder coatings curing degree and detection method