Film coating thickness measurement on wires

DeFelsko manufactures a wide range of handheld, non-destructive coating Thickness Gauges that are ideal for measuring coatings on wires.

Measurement challenges

Non-destructively measure the thickness of non-magnetic coatings on wires and small-diameter substrates.

Coating thickness measurement solutions

Option 1

The PosiTector 6000 F Micro Probe Series consists of 3 gauges that measure coatings up to 45 mil (1150 microns) thick and are suitable for non-destructive measurement of most coatings down to 80 mil diameter (14 standard gauges) of ferrous wire. For best results on small diameters, a quick-release adapter with a V-groove ensures good alignment, converting ferrous microprobes into constant pressure probes. Repeatability can be further improved by mounting the microprobe on the probe holder to ensure repeatable positioning of each part. 45 and 90 degree miniature probes can also be used for hard-to-reach measurement locations. Three PosiTector 6000 N miniature probes are designed to measure slightly larger diameter non-ferrous (non-steel) wires.

The measurement process is simple. The instrument is zeroed on the bare wire, which is called a calibration adjustment. Precise and repeatable measurements can then be made on coated parts with similar substrates and diameters. To simplify the measurement process, applicable PosiTector 6000 models store calibration adjustments over time, possibly one for each circuit substrate and diameter. With accuracy as low as 1% and resolution down to 0.01 mil (.5 micron), all probe types offer excellent performance.

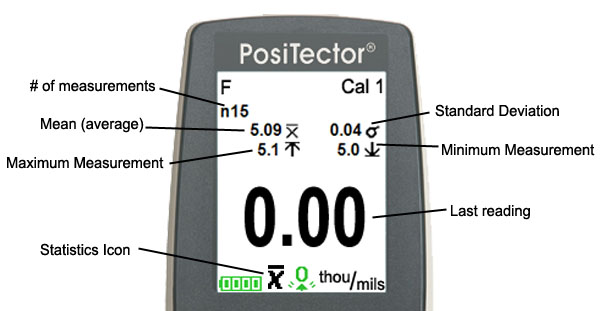

The advanced model of the PosiTector 6000 (marked "3" in the model name) has a variety of powerful features that make it ideal for these types of measurement applications. For statistical process control, the instrument continuously displays and updates the number of readings, averages, standard deviations, minimum and maximum thickness readings at the time of measurement. In addition, the HiLo function can set upper and lower limits, providing the operator with audible and visual alerts when any measured value exceeds a specified limit. For record keeping, up to 1,000 readings can be stored in 1,000 different batches for future analysis and download.

Option #2

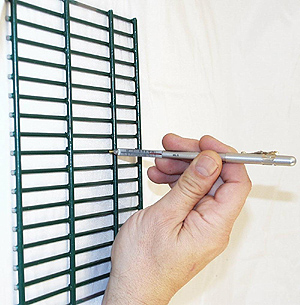

The PosiPen mechanical meter offers a cost-effective alternative with similar measurement capabilities, but it offers lower accuracy and resolution. The advantage of the PosiPen, in particular, is the ability to measure thermal applications directly without damaging the probe.

Line coating on the background

Common coating applications?

Most wires sold today have a protective coating to prevent abrasion, damage, and corrosion. Some common wire coatings include chrome, porcelain, galvanized, aluminum, epoxy, polyester, polyethylene, polyvinyl chloride, and coatings.

Steel rod oven chrome plating is mainly cosmetic while providing some protection against corrosion. They are often used as warm hangers.

The porcelain coating of iron and steel rod grills prevents food from sticking and corrosion. The quality of the grill is directly related to the thickness of the rod and porcelain coating.

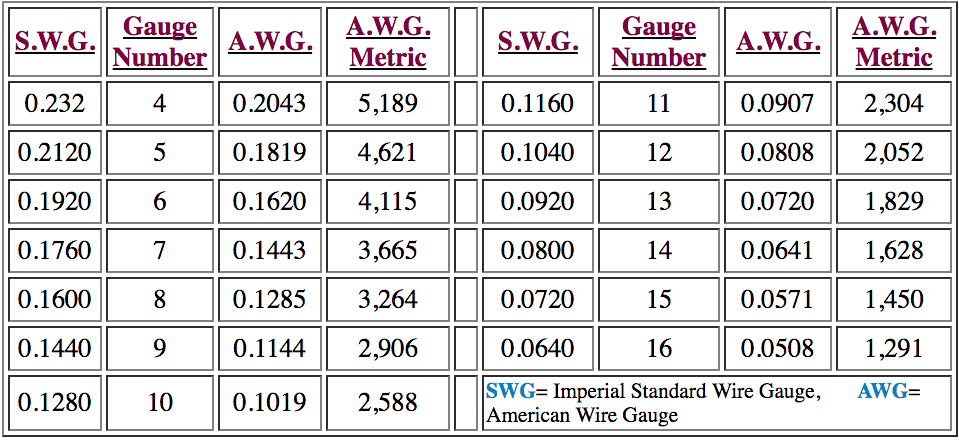

Galvanizing is the main coating of chain mesh fences, which is widely used in tennis courts, stadiums, parks, industrial units or any place that needs security. Chain Link fencing fabrics are available in a variety of sizes with wire sizes ranging from 16 to 4 (64 to 232 mils). Zinc is a self-sacrificing element that dissipates slowly, protecting steel from corrosion. Therefore, the life of the protection is directly related to the thickness applied. The quality of chain link fencing is determined by the specification of the thread and the thickness and consistency of the galvanizing.

Wire gauge and diameter conversion diagrams

Galvanized wire mesh is usually made of low carbon 12-14 standard wire. It is used as a reinforcement for the roof and ground of buildings, as a partition wall for walls, and as a fence for animal cages, kennels, fish gardens, lobster traps, gardening and sports field security.

Aluminum and aluminum alloys are also used as corrosion protection for steel chain fences. When coated with the same thickness, aluminized wire can be up to five times more corrosion-resistant than galvanized wire.

Epoxy coatings are commonly used to protect steel bars, wire meshes and force transfer rods. Epoxy coatings are typically available in sizes ranging from 7 to 12 mils (175 to 300 microns) and can be used as low as 5 mils (125 microns).

Polyester powders such as nylon are coated on wires such as laundry baskets, shopping carts and bike racks. Dishwasher baskets may contain 10 to 25 mils (250 to 625 microns) of coating, where bike racks may only require 6 to 8 mils (150 to 200 microns). Nylon coatings are popular for their attractive appearance because they provide protection against corrosion, cleaning and rinsing agents, moisture, abrasion, abrasion, stains, and impact resistance.

Due to its anti-corrosion barrier, polyethylene is a common thermoplastic coating used in refrigerator racks. Polyethylene is considered safe for contact with food, medicine, and drinking water. Its features include consistent custom coloring, good impact strength, economy, high gloss, smooth surface, good durability and flexibility, good adhesion, high single-layer thickness, simple and easy coating, anti-corrosion, and enhanced product appearance and feel. Thermoplastic coatings are also used on bicycle frames because of their high impact resistance (bike-friendly) and UV stability with thicknesses ranging from 8 to 12 mils (200-300 microns).

Polyvinyl chloride (PVC) is a powder coating that balances properties such as softness, rubbery feel, and abrasion resistance. PVC powders typically exhibit excellent impact resistance, chemical resistance, outdoor durability, color uniformity, and toughness. As a result, PVC is commonly used in bicycle racks, dishwasher baskets, and food contact applications such as refrigerator racks and freezer baskets. Aesthetically pleasing, extruded PVC coatings are typically galvanized with 6 to 14 gauge galvanized fence lines to provide additional environmental and anti-corrosion protection. Extruded PVC coating is applied to galvanized cores up to 25 mils (625 microns) thick. Vinyl powder coatings produce a uniform finish with thicknesses starting at 7 mils (175 microns) in a single application. Extruded PVC coating is a high-strength galvanized steel chain fence fabric for industrial, commercial, and institutional applications. Extruded fabrics are included in local, state, and federal government specifications for use in prisons, highways, docks, airports, housing, forestry, and military use.

Low lead and zinc coatings are powder-coated to large iron and stainless steel bird cages. Iron cages require full coverage and bond strength to prevent the risk of toxic poisoning from peeling paint or iron cages.

Why measure?

Despite the wide range of coatings available, the common denominator is that corrosion and protective coating applications often have a permissible range of thicknesses. If the thickness is too thin or too thick, premature failure may occur. There are many variables that need to be controlled in the process of coating small diameters, such as wires. Consider the powder coating process where the preheating temperature and time, the impregnation time, and the post-heating temperature and time all affect the final coating thickness.

Coating thickness variations need to be monitored and controlled to comply with applicable ASTM specifications and other applications where coating quality and cost need to be controlled. In addition, coating peeling and weighing ASTM standards can be quickly and inexpensively inspected using a coating Thickness Gauge.

Applicable Standards

A116-00 Standard Specification for Metal-Coated Steel Wire Woven Mesh Fence Fabrics

A185-02 Standard specification for steel wire welded steel wire reinforcement materials for concrete

A392-03 Standard specification for galvanized steel ring chain fence fabrics

A460-94 (2004) E1 Standard specification for copper-clad steel wire strands

A491-03 Standard Specification for Aluminum-Coated Steel Chain Fence Fabrics

A641/A641M-03 Standard Specification for Galvanized (Galvanized) Carbon Steel Wire

Standard Specification for A775/A775M-04A Epoxy Coated Steel Bars

A856/A856M-03 Zinc-5% Aluminum-Cerium Coated Carbon Steel Wire Standard Specification

A884/A884M-04 Standard Specification for Epoxy Coated Steel Wire and Welded Steel Wire Reinforcement

F668-04 Standard specification for polyvinyl chloride (PVC) and other organic polymer coated steel chain grid mesh fabrics

F1043-04 Standard Specification for Frame Strength and Protective Coatings for Chain Guardrail Frames for Metal Industry

ASTM F1345-96(2003) Standard Specification for Zinc-5% Aluminum-Mixed Rare Earth Alloy Coated Steel Chain Hoop Fabrics

F1553-01 Standard Guidelines for Industrial and Commercial Chain Guardrails

F1664-01 Standard specification for polyvinyl chloride (PVC) composite steel wire drawn wire with chain guardrail

Federal Specification RR-F-191 Type IV, Fencing, Wire & Postal Metal (Chain Fence Fabric)

National Association of Road Transport Officials (AASHTO) M-181 (2002) chain link guardrail

Other weight-dependent standards for thickness measurements:

A111-99A(2004) E1 Standard specification for galvanized (galvanized) "iron" telephone and telegraph lines

A121-99 (2004) Standard specification for metal-clad carbon steel barbed wire

A363-03 Standard specification for galvanized (galvanized) steel overhead ground wires

A475-03 Standard specification for galvanized steel wire rope

A603-98 (2003) Standard specification for galvanized steel structure wire rope

A741-98 (2003) Standard specification for galvanized steel wire ropes and fittings for highway guardrails

A809-03 Standard specification for aluminized (aluminized) carbon steel wire

A817-03 Standard specification for metal-coated steel wire for steel wire fence fabrics and tension wires

A824-01 Standard specification for metal-coated steel wire tensile steel wire with chain guardrail

A854/A854M-98 (2003) Standard Specification for Smooth High Tensile Guardrails and Grid Lines for Metal-Coated Steel

A975-97 (2003) Standard specification for double-twist hexagonal mesh gabion and Revet mattress pads (metal-coated or metal-clad wire with polyvinyl chloride (PVC) coating).

- 1Nondestructive measurement of dry coating thickness

- 2Coated steel coatings - Determination of dry-film thickness

- 3Application scheme of coating thickness test on wood board [with test video]

- 4Curved plastic coating thickness test application scheme [with test video]

- 5PosiTector200C ultrasonic coating Thickness Gauge on concrete coating thickness measurement application

- 6Coating Metering rodsFAQ

- 7Measuring method of nondestructive heat spray-on lining thickness

- 8Coulomb Thickness Gauge FAQ and Its Solutions

- 9What are the FAQs for paints Thickness Gauges? How to solve it?