Measurement of outdoor climate conditions

The handheld, non-destructive instruments produced by DeFelsko are ideal for measuring climatic conditions before, during and after coating application or coating in an external environment.

Measurement challenges

The main challenge was to establish a simple method to verify the surface and climatic conditions that can be used to protect coatings and linings.The convenience of regular measurements is also important because: Conditions are always changing, and different microclimates can be close to each other.

Conditions are always changing, and different microclimates can be close to each other.

The ability to document results may also serve as evidence to observe these conditions before, during, and after work.

Climate Observation Solutions

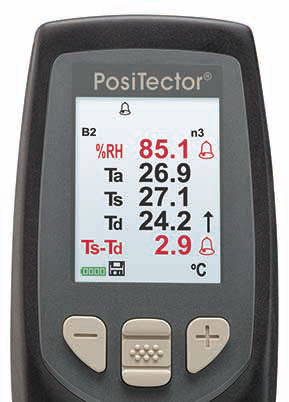

The multi-purpose PosiTector Dew Point Meter (DPM) is suitable for continuous measurement of air temperature, surface temperature, and relative humidity percentage. By placing the instrument near the structure to be coated or lined, the dew point meter has a built-in software feature that calculates the dew point temperature and the difference between the surface temperature and the dew point temperature. Figure 1 shows an example of a liquid crystal display provided by a dew point meter. It shows the ambient air temperature (Ta), surface temperature (Ts), relative humidity (RH), dew point temperature (Td) and surface temperature minus dew point temperature, which are key indicators of the probability of condensation molding. If the PosiTector DPM detects a small difference (delta value), three things happen: the contrast of the display is reversed, the red LED glows, and the meter beeps an alarm. See below for a demo of Alert Mode.

Figure 1. PosiTector DPM Alarm Mode

At any given time, all five climatic conditions observed and calculated, plus date and time, can also be saved in memory at the touch of a button. The dew point meter also features a unique auto-recording feature that automatically records a data set containing all 5 climatic conditions for a user-selected time interval. This is useful for maintaining a complete record of environmental conditions and trends during, during, and after coating use.

The dew point meter is designed to protect it from micro-climate changes caused by factors such as the operator's hands or direct sunlight, while still being able to sensitively identify shadow areas, cracks, and small temperature changes in exposed areas.

Alternatives

Traditionally, relative humidity has been calculated using wet-bulb and wet-bulb temperature measurements obtained from a rotary or electronic hygrometer (also known as a sling heart rate monitor). furthermore In order for these instruments to continue to rotate (spin) at a steady speed for 90 seconds, a temperature reading needs to be taken immediately, as it will begin to change as soon as the gyration stops. Relative humidity and dew point temperature need to be estimated using psychological tables, charts, and/or slide rules. Finally, the results need to be compared with another separate device - a surface temperature thermometer. For regular observation, the process needs to be repeated throughout the coating and lining application process. If continuous measurement of air temperature and relative humidity is required, additional recording instruments are required.

In order for these instruments to continue to rotate (spin) at a steady speed for 90 seconds, a temperature reading needs to be taken immediately, as it will begin to change as soon as the gyration stops. Relative humidity and dew point temperature need to be estimated using psychological tables, charts, and/or slide rules. Finally, the results need to be compared with another separate device - a surface temperature thermometer. For regular observation, the process needs to be repeated throughout the coating and lining application process. If continuous measurement of air temperature and relative humidity is required, additional recording instruments are required.

The versatile, one-handed dew point meter is an easy-to-use instrument because it uses its sensitive and accurate sensors, high-quality electronics, and feedback from software to perform all calculations electronically. The result is an instrument capable of taking immediate continuous readings that are not affected by operator interpretation and measurement errors, as well as calculation and rounding errors associated with the use of look-up tables. The advantages of a dew point meter are well illustrated by the illustrated application, which involves applying a large water tower. Consider the requirements for measuring and documenting climatic conditions while painting, and then compare the use of these two methods and the equipment required on scaffolding 50 meters (160 feet) above the ground.

Background to climate measurements

What is an app?

Surface treatment and coating application should be carried out under favorable environmental conditions to prevent potential coating failure. The main factors influencing the long-term performance of steel coatings are the climatic conditions in the pretreatment and coating applications. The PosiTector Dew Point Meter (DPM) is an electronic device that enables contractors, inspectors, and owners to measure and document all applicable environmental conditions.

Why measure?

The main reason for measuring climatic conditions is to avoid rework and premature failure of protective coatings. Recommendations and requirements are contained in various internationally recognized standards. Below is a brief summary of the recommendations and requirements for climatic conditions cited from international standards...

Temperature - It is very important to measure surface and air temperatures, as they are often different. Applying at incorrect temperatures can lead to defects including: blistering, pinholes, dimpling, dry spraying, and mud cracking. Factors such as direct sunlight, shadows, shape, and mass of the coated object can create unexpected thermal behavior on the surface. At night, metal structures emit heat and are cooled below air temperature, while during the day, they absorb heat and are usually warmer than air. By measuring the surface temperature, potential application problems can be avoided if the air or surface temperature becomes too hot or too cold for unsatisfactory film formation. Surface and air temperature directly affect the curing rate of the applied coating or lining system and are a major contributor to the formation of surface moisture or dew. ASTM D3276-00 Standard Guide for Paint Inspectors (Metal Substrates) states that a minimum air/surface temperature of 40ºF (5℃) is typically required. However, for "cold-cured" one or two component systems, it can be as low as 0ºF or -18℃. Painting should not be done when the temperature drops and is within the lower limit of 5ºF (3℃).

Relative Humidity - Relative humidity refers to the amount of moisture in the air expressed as a percentage of total volume. High relative humidity can slow down the rate of solvent evaporation. For this reason, the maximum relative humidity that can be applied and cured by a coating or lining is usually set at 85%.

Dew Point Temperature - The dew point is the temperature at which moisture begins to form on the surface. The dew point temperature is a function of air temperature and relative humidity. (See ISO 8502-4 Annex A). In order to achieve saturation, the temperature of a certain volume of air needs to be cooled. Some major standards organizations require serious dew point control. Moisture on a freshly exploded steel substrate can cause steel rust. If there is a thin, invisible film of moisture between the applied coating and the substrate, the system may fail prematurely. To ensure that there are no dew point issues, ISO 8502-4 and SSPC guidelines state that surface temperatures need to be at least 5ºF or 3℃ above the dew point during the 3 critical phases of coating preparation, application, and curing.

Where is the market?

For contractors involved in surface preparation, protective coatings or linings for large structures are excellent choices for dew point meters. Coatings and lining contractors face an incredibly large market in industries that face the rising cost of adding to existing structures, replacing and maintaining them. These cost pressures enable equipment such as dew point meters to help ensure successful coating and lining applications, which are invaluable in reducing the cost of rework and premature structural damage due to improperly applied protective coatings.

- 1How does dew point temperature affect the coating process?

- 2How to non-destructively test the water content of concrete slabs?

- 3Handheld Dew Point Meter DT-8321 Operation Instructions

- 4Remote monitoring of dew point instrument under environment conditions

-

-

-

-

-

LANDTEK HT-6292 dew point meter$ 267.00

-