Learn from the policy orientation of European and American countries on VOC emissions from the Coating Industry

In the United States, people have realized that the ozone content requirements in the National Ambient Air Quality Standard (NAAQS) can be met by reducing VOC emissions. Therefore, a series of laws and regulations for the control of VOC pollution in the coatings industry have been formulated and implemented to promote It has improved the industry's technological level and the development of pollution control technology, effectively reduced VOC emissions, and greatly promoted the environmental protection work of the coatings industry. This study analyzes VOC pollution discharge standards, management strategies, and control technologies in the U.S. coatings industry, and provides some enlightenment for my country's future VOC comprehensive prevention and control work in this field.

.

At this stage, my country's VOC control has just started, and problems such as weak system, poor industry pertinence, and incomplete control are more prominent. Such as emission standards, currently the main implementation of the "Comprehensive Emission Standards of Air Pollutants" (GB1627-1996), the indicators related to VOC emissions are only 16 kinds of benzene, toluene, xylene, phenols, formaldehyde, acetaldehyde, acrylonitrile, etc. Meet the requirements of pollution control; In terms of waste gas treatment, the product type is single, the technical level is backward, and the product operation and maintenance are poor. my country will list VOC as a key pollutant during the "Twelfth Five-Year Plan" period, with "three regions and six groups" (Beijing-Tianjin-Hebei, Yangtze River Delta and Pearl River Delta regions, central Liaoning, Shandong Peninsula, Wuhan and its surrounding areas, Changzhou-Zhuzhou-Tanshan City clusters such as Chengdu, Chongqing, and the west coast of the Taiwan, CHINA Strait) are key control areas to promote the joint prevention and treatment of VOC pollution in typical industries that use a large amount of organic solvents such as coatings. Therefore, it is necessary to learn from foreign VOC comprehensive prevention and control policies, regulations and technologies. Valuable experience. However, there are few reports on the research on VOC pollution control strategies in the foreign coatings industry.

The paint industry is one of the main sources of VOC pollution in my country. It is estimated that the VOC emissions from the use of paint in my country in 2010 were about 2.235 million tons, accounting for 13% of the total VOC emissions from anthropogenic sources in the country that year. Due to the large amount of volatile organic solvents and additives used in the paint base, more than 50% of VOCs in solvent-based paints are emitted into the atmosphere during the painting process, and most of them contain benzene, which can cause poisonous or even carcinogenic effects on human internal organs. Poisonous and harmful substances such as toluene, xylene, chlorobenzene, butanol, cyclohexanone, cyclohexane and butyl acetate. After some VOCs with photochemical reactivity are discharged into the atmosphere, they will form ozone, photochemical smog, etc. through complex chemical and photochemical reactions with NOx and other gases, which will eventually endanger human health and regional ecological environment safety.

1 VOC Pollution Control Policy and Technology in the United States

1.1 Federal Government Policies and Regulations

1.1.1 The Clean Air Act (CAA) and its amendments

CAA is the basic law for environmental air quality protection in the United States. The US Environmental Protection Agency (EPA) established a series of important laws and regulations such as NAAQS on the basis of this law as a supplement, which constitutes the Federal Core Regulations (CFR). The Clean Air Act Amendments Act (CAAA), passed in 1990, required stringent measures to reduce VOC emissions by 70% by the year 2000 [8]. In terms of control of the coatings industry, the VOC (diluted) emission limit for industrial coatings is stipulated to be 420g/L. 70% of the 189 prohibited or restricted toxic and hazardous substances listed by CAAA are VOCs, including methanol, methyl ethyl ketone, toluene and other organic solvents commonly used in almost all coatings.

1.1.2 New Pollution Source Performance Standard (NSPS)

In order to promote the popularization and use of air pollution control technology and alleviate air pollution problems, taking into account factors such as technology cost, health and environmental impact, and energy demand, NSPS was formulated according to the Clean Air Act of 1977, which defines limits and targets. Specific emission unit detection methods and VOC emission limits, etc., the paint industry standards that have been promulgated so far include VOC emissions from surface spraying operations such as automobiles and light trucks, metal furniture, large household appliances, metal coils, beverage cans, pressure-sensitive tapes, and labels standard.

1.1.3 National Emission Standards for Toxic Air Pollutants (NESHAPs)

As required by Congress, EPA is required to establish standards and regulatory measures to control sources of hazardous air pollutants that cause cancer or other serious health effects. On July 16, 1992, EPA announced the first list of toxic air pollutant sources, which included industrial surface coating VOC pollution sources. In order to ensure the effective reduction of such pollutants, EPA has formulated national emission standards for hazardous air pollutants listed by CAAA according to different pollution sources. Table 1 shows the organic toxic air pollutants (OHAP) limit requirements for some industrial maintenance surface coatings. . In order to reduce the emission of HAP as much as possible, EPA has specially set up the highest achievable control technology (MACT) to meet the limit requirements through good clean production process, control technology and operation means. Implement strict air pollution reduction measures for HAP pollution sources. For existing pollution sources, ① if there are more than 30 similar pollution sources, the MACT bottom line should reach the average limit of the top 12% enterprises; ② if there are less than 30 similar pollution sources, it should reach the average limit of the top 4. For new pollution sources, a good level of control must be achieved for existing similar pollution sources.

1.1.4 Control Technology Guidelines (CTG)

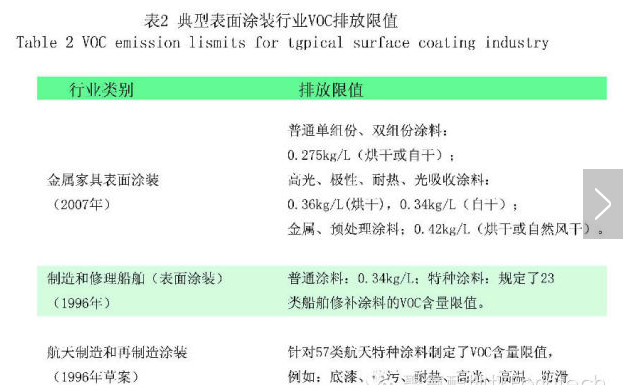

Section 183(e) of the Clean Air Act requires the EPA to regulate emissions of VOCs from consumer and commercial products. In order to supervise VOC pollution sources and assist countries and localities to meet air quality standards, EPA has compiled CTG, which puts forward specific emission limit requirements and control measures for shipbuilding, furniture, and large-scale home appliance coating (see Table 2). Although CTG is not a regulation, states must use it as a guiding document to formulate corresponding legal standards as part of the emission reduction plan.

1.1.5 National VOC emission standards for consumer and commercial products

(1) VOC emission standards for architectural coatings

A survey conducted by EPA on the VOC release of consumer products and industrial products found that the VOC release of architectural coatings accounts for about 9% of all consumer products and industrial products, and architectural coatings are more closely related to people's lives, so the standard's The formulation and implementation are of great significance for reducing air pollution and protecting the ecological environment. From September 13, 1999, the production and distribution of architectural coatings in the United States will be implemented in accordance with the requirements of this standard.

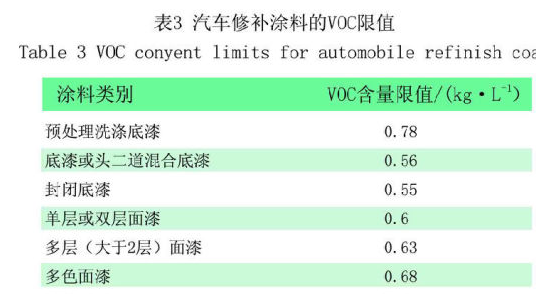

(2) VOC emission standards for automotive refinish coatings

Automobiles such as passenger cars, trucks, trucks and other mobile equipment sold and distributed in the United States after January 11, 1999, the coating and repair coating requirements for parts and components shall be implemented in accordance with this standard (see Table 3)

(3) VOC emission standards for aerosol coatings

The EPA believes that by controlling the emission of VOCs with high chemical reactivity, the ground ozone concentration can be more effectively reduced. Therefore, the EPA has adopted the VOC emission standard for aerosol paint based on the control of chemical reactivity limits. This standard stipulates the calculation method of the chemical reactivity value of the product, and proposes to establish relevant product identification and records for the supervision objects (manufacturers, importers, and distributors indicated on the label of the aerosol product or the specified product formula) , Reporting requirements. The standard will be implemented on January 1, 2009, and the latest implementation time will be January 1, 2011.

1.2 Local regulations

In addition to the above-mentioned federal regulations and control technical guidance, various regions have also established strict restrictions on VOC emissions.

1.2.1 Regional regulations

为促进区域性污染物的综合治理,美国设有多个区域性的管辖区,如南海岸空气质量管理区(AQMD)、加州空气资源委员会(CARB)、东北臭氧迁移委员会(OTC)等。

以AQMD为例,针对游艇、金属零部件及产品、汽车生产线、金属容器、密封件和线圈、电磁线、气溶胶涂料、木材产品、建筑等方面的涂料使用均有具体的VOC标准,并According to需要不断更新。如为控制大小船舶及其辅助设备、海上浮标、石油钻井平台等方面海洋涂料的VOC排放设立了1106条例(游艇另设专门的规定),规定了详细的涂料VOC含量和排放限值、可替代的污染控制措施及VOC削减效率核算方法、VOC检测分析手段。

1.2.2 州级法规

一般情况,各州须According to自身的实际情况,以州实施计划等形式制定控制要求,强制性要求其他政府部门、企业、机构共同控制和减少污染。如纽约州1979年7月24日生效的《表面涂装工艺州实施计划》,要求企业严格按照该法规要求执行以下条款:① 申请表面涂装生产线许可证;② 提供合理可达到技术(RACT)的检测报告;③ 安装污染控制设备,并限定生产线VOC排放量;④ 定期向环保局提交记录报告,上报生产过程中原料(包括溶剂)的购买量、使用量和产量,生产工艺中VOC实际含量,污染控制设备的去除效率数据;⑤ 企业自行测定涂装生产线的挥发性有机物质含量、水含量、密度、固体体积和固体质量来确定实际的VOC含量(取样和分析的方法由相关法规规定);⑥ 溶剂的贮存清洗需采用防止泄露和挥发的控制措施。

1.3 VOC治理技术

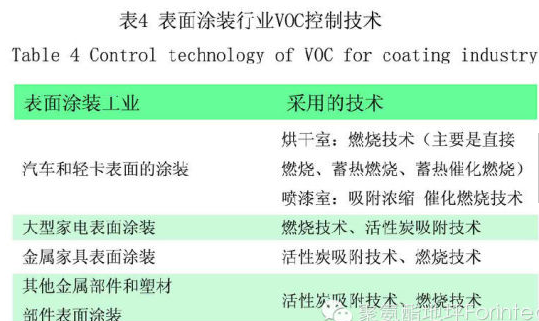

美国海湾地区空气质量管理区(BAAQMD)指导文件、加州空气污染控制协会(CAPCOA)信息中心、清洁空气技术中心(CATC)空气污染技术报告等均提供了典型行业很好的可行控制技术(BACT)的技术信息,用以协助企业达标排放。其中,涂料行业常用的控制技术主要分为两类:燃烧技术和吸附技术。燃烧技术主要用于烘干室排放的含VOC废气的治理;吸附技术处理低浓度的喷涂室排放的尾气。各行业的表面涂装VOC控制技术见表4。

1.3.1 燃烧技术

直接燃烧法适用的VOC污染源广泛,特别是高浓度低风量地区的VOC废气。一般直接热力燃烧器的处理风量在0.24~24m3/s。适合的进口浓度为1500~3000×10-6(体积分数,下同),该浓度范围可以保持反应器维持在高温并且不需要添加额外的燃料。换热燃烧法则适用于0.24~24m3/s的气流。综合考虑经济和技术性,最适用处理的浓度范围是1500~3000×10-6,一般最高处理浓度需要低于1/4的爆炸极限浓度。直接燃烧和换热燃烧反应器具有很多相似之处:① 正常工作温度均在590~650℃之间,处理有害污染物时操作温度可达到980~1200℃;② 均不适宜处理含卤素或含硫废气,因为生成的HCl、HF和SO2等强酸性化合物会腐蚀反应器;③ 一般不需要前处理措施;④ 处理低浓度高流量的废气经济性较差。

蓄热燃烧法适用于治理浓度小于1000×10-6、风量大于2.4m3/s的VOC废气。该法的处理风量范围在2.4~240m3/s之间,适于浓度小于100×10-6的气体。废气进入反应器前需要预先去除颗粒物,工作前采用天然气燃料预热气体使温度升至760~820℃(最高操作温度1100℃)。反应器中加入贵金属催化剂可以降解含氯等卤族气体,但废气中存在硅、磷、砷等其他重金属物质会使催化剂中毒。催化燃烧法适宜的废气流量在0.33~24m3/s,可以处理浓度低于1×10-6的废气。由于使用了催化剂,其反应温度比热力燃烧的温度低,废气进入催化剂床层前采用辅助加热器加热至320~430℃,催化剂最高设计工作温度可达540~675℃。

1.3.2 吸附技术

吸附技术可将VOC浓度从400~2000×10-6降低至50×10-6,处理废气的浓度范围在20×10-6到1/4爆炸浓度极限之间,风量大于2.4m3/s。常用的吸附剂有活性炭、有机聚合物、沸石等。活性炭的更换频率是6个月至5a,虽然活性炭的更换频率比沸石和有机聚合物高,但价格便宜,因此应用相对广泛些。活性炭的再生温度是218~318℃,再生后的吸附容量约为初始吸附容量的50%。通常活性炭吸附装置后还可以连接燃烧/催化燃烧反应器或者冷凝器进一步降解或回收VOC。

1.3.3 控制技术经济分析

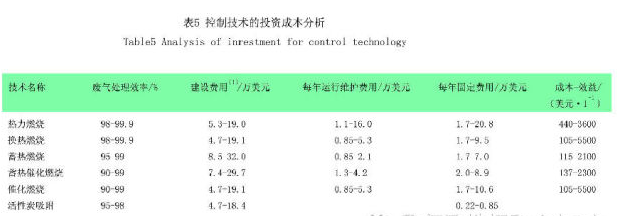

EPA对典型操作条件下的热力燃烧、活性炭吸附(采用蒸汽再生活性炭)等控制技术进行了的经济分析(不包括前处理费用),如表5所示。

2 实施效益与成本评估

美国逐步颁布的涂料行业VOC污染的控制法规,特别是1990年的CAAA,对VOC污染物的排放提出了极为严格的限制要求,其中第183(e)款要求EPA需要以很好的可行控制(BAC)规范企业生产行为,即在综合考虑技术经济可行性,健康、环境和能源影响的基础上,所确定的排放管理控制手段需要采用有效的设备、措施、工艺、方法、系统或技术,包括化学配方重组、原料或产品替代、重新包装、使用、消费、存储或处置等[23]。基于这些规定,随后制定和完善的一系列法规标准促使工业界不断改进工艺和创新涂料配方、升级治理技术,极大地减少了VOC排放量,使涂料使用过程中挥发的VOC总量从1994年的568万t减少到2006年的389万t,取得了骄人的成绩。以下是部分典型行业排放标准的VOC削减效益和成本影响评估。

为达到《国家建筑涂料VOC排放标准》,通过推行对低VOC含量涂料提供经济鼓励等可促进产品达到BAC的要求。另外产品配方重组被认为是在经济技术上最可行的策略,包括涂料中VOC含量的适当调整,树脂技术的改动。该法规的实施可减少约103000t/a的VOC污染物,排放量较1990年降低202%。总而言之,建筑涂料VOC排放标准的实施不仅能够减少VOC的排放、臭氧生成和有害空气污染物的排放,同时也会有利于人们健康和环保。在1990年的工业调查中有64%的产品符合建筑涂料标准规定的VOC含量要求,其余不合格产品调整的花费主要来自新产品的开发、市场调研测试。据EPA估计生产商、进口商支付超标费用,产品的使用者更换涂装设备,产品的记录、汇报和检测这3个主要环节,共花费2800万美元。通过成本效益分析,法案实施后每减排1tVOC消耗250美元,对建筑涂料的市场价和产量影响不会超过0.1%。

在美国的《国家汽车修补涂料VOC排放标准》中,EPA将生产商和进口经销商作为有效的控制对象,依靠现有的国家和地方法规、涂料产品信息、汽车修补涂料行业反馈的信息,确定VOC限值标准的技术和经济可行性。此外,由于汽车涂料中所含VOC也属于有害空气污染物(HAP)的范畴,因此汽车制造业也通过采用各种OHAP减排技术的组合降低表面涂装过程的VOC排放量,如使用低HAP含量的涂料,提高涂料利用率、控制烘干炉尾气以及控制溶剂型涂装生产线自动化喷枪的排气等。该法规预期可减少32500t/a的VOC排放,与1995年相比排放量减少33%。实施成本包括涂料制造工艺改造成本,对涂料生产者、经销商、个体户培训的费用,成本约为450万美元/a,涂料价格和平均维修费用上涨0.2%。但与其他具有潜在可用性的控制方法相比,可预测的经济的冲击很小,也更具经济优势。

EPA estimates that after the implementation of the National Aerosol Paint VOC Emission Standard, the reduction of VOC emissions can reach 15570t/a, which is 19.4% lower than that in 1990. The emission reductions are mainly concentrated in the aerosol spray paint manufacturing industry, and the impact on the spray paint use industry, spray paint wholesale industry and spray paint import industry is much smaller. The price of raw materials, the cost of technological innovation, the cost of keeping sewage records and reporting compliance will increase to a certain extent.

- 1Synthesis, curing and application of phenolic resin

- 2Types of Amino resins and Their Applications in Coatings

- 3Amino resin performance detection method

- 4Comparison of key parts configuration list of XD-1JQ-A1 formaldehyde box and XD-1JQ-F1 formaldehyde box

- 5Gas detection Common detection items/detection methods and testing standards

- 6Influence of hot pressing process and environment parameters on TVOC and formaldehyde release from particle board

王敬贤;沈隽 - 《生物质材料科学与技术教育部重点实验室》

- 7Amino resin Coatings Overview

- 8Possible causes and countermeasures of formaldehyde content exceeding standard in emulsion paint

- 9Biaozhi GM8801 Formaldehyde Tester Instructions for Use