How does PHYNIX Coating Thickness Gauge solve cast iron surface coating measurement?

Measurements of the changes in metals, their magnetic and electrical properties, need to be considered on hot surfaces at higher temperatures . When measuring on hot surfaces with Sufix® standard probes (0.2 mm and 1.5 mm measuring ranges), calibration is usually not necessary, as the sensor becomes insensitive to changes in magnetic permeability and electrical conductivity.

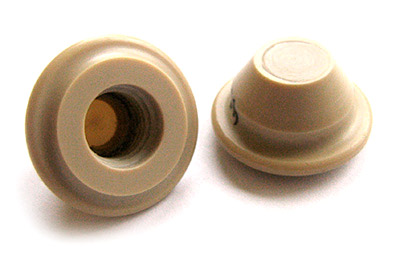

Hot surfaces up to 300°C can be reliably measured using the High Temperature Contact Ring (Product No. 10844). Measuring probes FN 1.5 or F 1.5 (measuring range 1.5 mm) do not require much manipulation and are easily carried out by mounting screw contact rings. This contact ring can measure thicknesses up to 1,000 µm on hot surfaces.

The program is widely used in:

foundry industry

Electroplating industry

Paint industry

Automobile industry

aerospace industry

shipbuilding

This solution has the advantage of being clear at a glance, simply changing the probe prism installation, and is compatible with all standard probes

technical specifications

- 1The Working Principle of Gel Conductivity Meter Has Been Detailed

- 2Detection Principle and Application Analysis of Conductivity Meter

- 3Principle of Conductivity Analyzer

- 4Several common electrode types for Conductivity Meters

- 5Differences between three STIP-scans: pH Meter, Conductivity Meter, and Dissolved Oxygen Meter

- 6Conductivity Meter and Ion Meter specific differences

- 7Common types and application differences of STIP-scan

- 8How to detect the conductivity of lithium battery coating slurry?

- 9How to choose a high temperature Thickness Gauge?