Varnish, Clear Oil and diluting Agent Appearance and Transparency Determination

1 Definition, Purpose and Significance

Transparency is the ability of a substance to transmit light. Transparency can indicate whether varnishes, varnishes, paints and thinners contain mechanical impurities and suspended solids.

Both varnish and varnish are colloidal solutions, and the degree of transparency or turbidity is caused by light scattering on the particles of the dispersed phase. In the production process, the purity of various materials, the mixing of mechanical impurities, the local overheating of materials, the mutual solubility of resins, the solubility of solvents in resins, the precipitation of drier and the infiltration of water will all affect the transparency of the product. Products with turbid and opaque appearance will affect the gloss and color of the film, as well as reduce the adhesion and resistance to chemical media.

2 Relevant standards

GB Hall 1721-79 (89) Appearance and Transparency Determination of Varnish, Clear Oil and Thinner

HG Hall 3379-2003 Perchlorethylene Thinner Appendix A Transparency Determination

3 Introduction to key points of inspection methods

3.1 GB Hall 1721-79 (88) Appearance and Transparency Determination Method of Varnish, Clear Oil and Thinner

3.1.1 Determination of appearance

At a certain temperature, visually observe whether the sample contains mechanical impurities under the transmitted light in the dark box.

3.1.2 Determination of transparency

At a certain temperature, visually compare with a series of standard solutions of different turbidity under the transmitted light in the dark box to evaluate the transparency of the sample.

3.1.3 Materials and equipment

Stoppered colorimetric tube: capacity 25ml

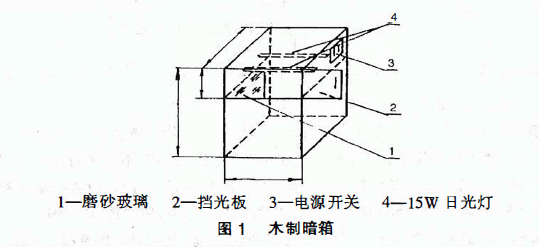

Wooden dark box: 500x400x600mm as shown in Figure 4

Transparency standard liquid: divided into colorless part and colored part. 3.1.4 Operation points

3.1.4.1 Determination of appearance

Put the sample into a dry and clean colorless glass colorimetric tube with a capacity of 25 ml, adjust the temperature to (23±2)°C, and observe whether the sample contains mechanical impurities under the transmitted light in the dark box .

3.1.4.2 Determination of transparency

Put the sample into a dry and clean colorless glass colorimetric tube with a capacity of 25 Kol, adjust the temperature to (23±2) °C, and compare it with a series of different turbidity levels under the transmitted light in the dark box. Standard solutions (use the colorless part for colorless ones, and colored parts for colored ones) for comparison, and select the closest primary standard solution for the sample.

3.1.5 Result presentation

Appearance The presence or absence of mechanical impurities in the sample is assessed by visual comparison.

The transparency standard liquid is divided into three grades, which are transparent, slightly turbid, and turbid, namely grades 1, 2, and 3 in the standard. The transparency level of the sample is directly expressed by the level of the closest primary standard solution.

- 1Paint transparency detection method

- 2Coating transparency and detection method

- 3Test method for transparency of ink

- 4Resin Appearance and Transparency Detection

- 5Transparency measurement: diffused light measurement and transmitted light measurement

- 6How to Measure the Transparency of Coatings?

- 7Determination of varnish transparency (turbidity) by photoelectric Glossiness Meter

- 8Coating liquid performance inspection -- Varnish, oil and diluting agent Appearance and Transparency Determination

- 9How to Measure Coating Transparency?