Color performance evaluation index of Pigment

1. Tinting power

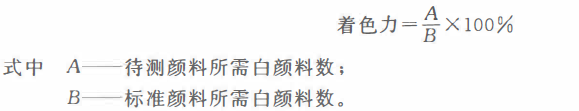

Tinting strength, also known as tinting strength, is the ability to characterize the color intensity of a pigment mixed with another benchmark pigment. Usually white pigments are used as a benchmark to measure the tinting ability of various colored or black pigments. . The degree of tinting strength is compared with the standard sample, expressed as a percentage of formula (2-1):

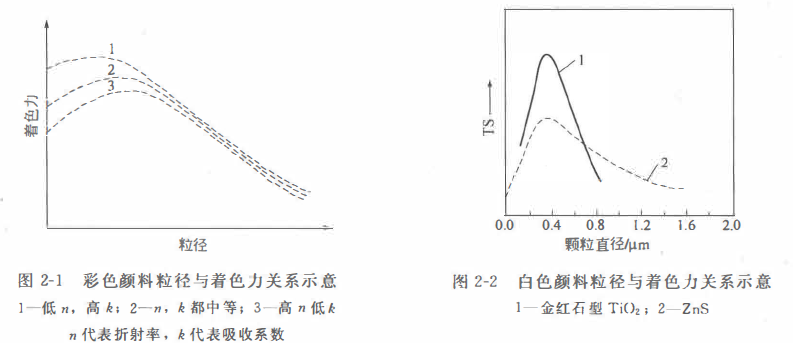

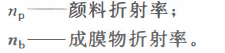

Tinting power is the result of the pigment's absorption and scattering of light, and mainly depends on the absorption. The greater the absorption capacity, the higher the tinting power. Tinting strength is an important index to control the quality of pigments. When pigments are colored with thousands of pigments, when the pigments with high tinting strength obtain the same tinting strength, the amount of pigments used is less than that of pigments with low tinting strength. The strength of tinting strength is not only related to the chemical composition of the pigment, but also depends on factors such as the size, shape, particle size distribution, product structure and dispersion of pigment particles in the coating film. The tinting strength generally increases with the particle size reduction of the pigment. When the particle size decreases to a certain extent, the tinting power will decrease due to the particle size reduction, so there is a good particle size that makes the tinting power stronger.

The coloring power of colored pigments fluctuates with the particle size far less obviously than that of white pigments with a large refractive index, and when the particles increase to a certain extent, the coloring power becomes very low, from the "left skew" shown in the coloring power curve , indicating that the selection of fine particle pigments can help improve the tinting strength.

It can be seen from Figure 2-1 and Figure 2-2 that the former is a color pigment, because the coloring power mainly depends on absorption, that is, it mainly depends on the nature of its chemical substances, so the relationship with the particle size is not very prominent, but the effect of absorption coefficient Larger, the coloring power of the larger absorption coefficient K value under the same particle size is stronger. The latter is a white pigment, its absorption is very small, at this time the coloring power mainly depends on scattering, because the scattering is closely related to the particle size, so the coloring power of white pigments changes significantly with the particle size, and the higher the refractive index , the pigment varies more significantly with particle size.

Tinting strength is also related to the degree of dispersion of pigment particles in the paint film, the better the dispersion, the stronger the tinting strength. In order to improve the tinting strength of the pigment itself, sufficient attention should be paid to the processing and post-treatment of the pigment, such as pre-dispersion, grinding, addition of additives and dispersion process. In addition, pigments with different chemical compositions also affect the coloring strength due to different particle shapes and crystal types. Therefore, there are many factors affecting the coloring strength, and the evaluation of the coloring strength must be analyzed from many aspects.

2. Decolorizing power

Achromatism refers to the ability of a pigment of one color to offset the color of another pigment. The stronger the coloring power of general pigments, the

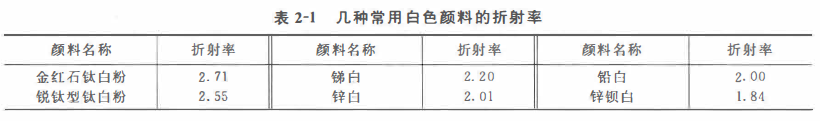

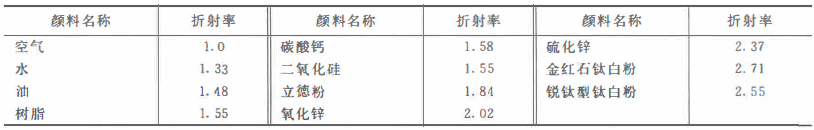

The color strength is also stronger and is usually used to rate white pigments. Generally speaking, the higher the refractive index, the higher the decolorizing power. Rutile Chin white powder has the largest refractive index among white pigments, and its decolorizing power is also the highest. The refractive index data of several common white pigments are shown in Table 2-1.

Table 2-1 Refractive index of several commonly used white pigments

3. Hiding power

The pigment is added to the transparent base material to make it opaque, and the minimum pigment required to completely cover the black and white grid of the substrate is called masking.

Covering power, usually expressed in g/m2, is the required coverage of dry pigment matter per square meter of substrate area. The hiding power (h center ng power) is due to the difference in refractive index between the pigment and the medium in which it exists. When the refractive index of the pigment and the base material are equal, it is transparent. When the refractive index of the pigment is greater than that of the base material, it will be covered. The greater the difference between the two, the stronger the hiding power. Rate data are shown in Table 2-2.

Table 2-2 Refractive index of several common substances

When the paint is applied, it is often found that the hiding power of the paint changes greatly when it is dry and when it is not dry, which is caused by the change of the refractive index when it is dry and when it is not dry. For example, when calcium carbonate is painted under the wall in a wet state, because it has a similar refractive index to water, it looks poor in hiding power, but after it dries, because air replaces water, the two The difference in refractive index becomes smaller, so it looks like the hiding power is greatly increased after drying.

The pigment particles in the paint should be wetted by the paint base. In order to increase the hiding power, a part of the body color with low hiding power can be added.

For example, when adding extender pigments in architectural coatings for proper filling, when the amount exceeds the CPVC, some pigment particles will be surrounded by air and will not be wetted by the paint base, which will increase the amount of pigment particles on the contrary. partially pigmented

Covering power. Use body pigments with low hiding power to replace part of the high-hiding and expensive white powder, which not only reduces the cost, but also does not affect the hiding power.

Hiding power is the result of the pigment's scattering and absorption of light, mainly by scattering. For white pigments, it mainly depends on scattering, while for colored pigments, absorption ability also plays a role, and high absorption black pigments also have strong hiding ability. Since the generation of hiding power is closely related to the optical process, when the chemical composition of the pigment is fixed, the particle size, distribution, crystal shape, and crystal structure are all related to the hiding power.

白色颜料主要是散射, 由散射而产生的遮盖力主要与洛伦兹 (Lorentz) 因子、 颜料粒 子大小和颜料浓度三个因素有关。 洛伦兹因子反映颜料与成膜物的折射率关系, 如式 (2-2)所示。

经验表明, 遮盖力与L的平方成正比。这说明颜料与成膜物的折射率差越大, 遮盖力就越高。颜料的遮盖力与粒径大小有关, 一般高折射率颜料与粒径关系较大, 低折射率颜料与粒径关系较小, 通过图2-3可以看出, 高折射率的颜料要比低折射率的颜料遮盖力强, 每条随粒度而变的遮盖力曲线都存在一个最高值。在很好的粒径产生最大遮盖力的原因是由于光的衍射作用, 当颜料粒径相当于波长的1/纵时, 效果很好的, 粒径再小时, 光线会绕过颜料粒子, 发生衍射, 就不能发挥最大遮盖作用, 同时随粒径变小, 透明度增强, 遮盖力下降。超过粒径的很好的状态时, 随粒径的变大, 光的散射作用越来越差, 遮盖力同样会下降。

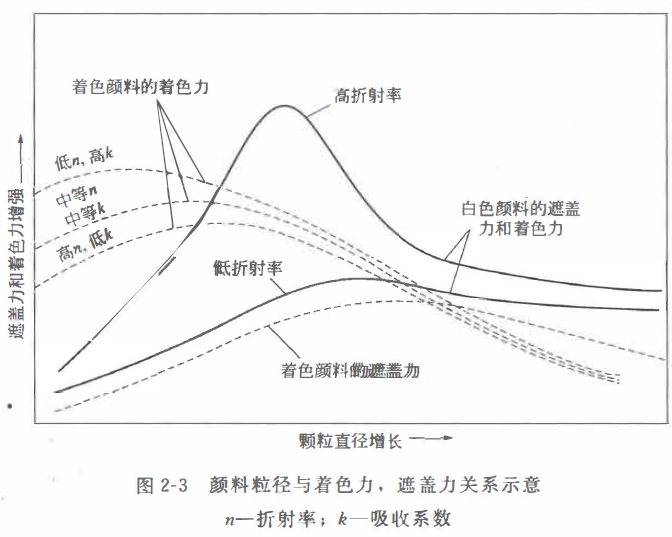

粒径对散射有较大影响。当粒径很小时, 散射很小。随着粒径的增大, 金红石型钦白粉、锐钦型钦白粉和硫化锌的散射迅速提高, 达到最大值, 而氧化锌和立德粉的散射相对较慢地提高至最大值。随着粒径的进一步增大, 散射下降。不同颜料的很好的散射粒径是不同的。当入射光为可见光的平均波长(入= 550nm), n 6 = 1. 55时, 常用白色颜料的很好的散射粒径列于表2-3 。

It can be seen from Table 2-3 that the best particle size of rutile Chin white powder is about half of the average wavelength of visible light. This is also the reason why the particle size of commercially available rutile-type chromium white powder is generally in the range of 0.2 to 0.4 μm. The pigment volume concentration has a certain degree of influence on the hiding power of the coating film. Studies have shown that when Chin white powder is lower than l0%PVC, the hiding power increases linearly with the increase of concentration; when its concentration exceeds 10%PVC, the hiding power increases with the increase of concentration, but not linearly; when its concentration exceeds 30%PVC Finally, due to the agglomeration of Chin white powder, the hiding power no longer increased with the increase of concentration, and even decreased slightly

- 1Summary of determination methods for hiding power of coatings

- 2Color difference meter and its application in Coating production

- 3Application of color reader in paper color difference control

- 4Pigment hiding power

- 5Principle, characteristics and application of Spinning & weaving precision color difference instrument

- 6Determination of Coating hiding power

- 7GB/T 23981.2-2023: Paints and varnishes - Determination of hiding power - Part 2: Checkerboard method - Interpretation

- 8Detection of film color retention with color reader

- 9Concept, influencing factors and determination method of Coating hiding power

-

-

-

-

Leneta WB sealed film, pure white$ 301.00

-

-