Spreader method of roller painting flow classification

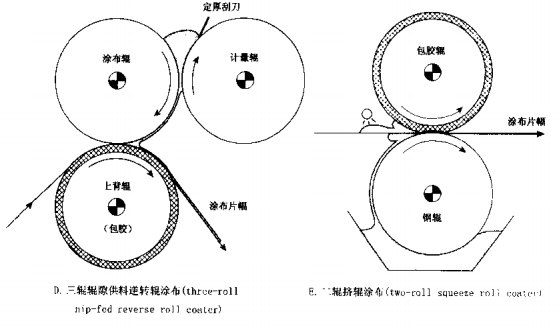

Coaters can consist of two, three, four or more rollers . The surface of the drum can be a smooth hard chrome layer on the steel surface, or a deformable roll covered with a thin rubber layer, or an anilox roll engraved with pits. The rollers can rotate in opposite or opposite directions, and there are many ways to feed the coating liquid. Although there seem to be many ways to roll coat, the basic modes of operation shown in Figure 3. can be combined into any type of roll coater.

An effective way to classify and delineate the way roll coaters operate is to break them down into a series of basic operating steps, each step involving the flow of liquid to the spoke gap. The operation steps in them can be regarded as an independent entity. The coating machine can be regarded as a whole composed of these related basic operation units. Usually a complex coating machine can have many basic operating units, but only one or two of them are important units. For example, in the reverse roller coater (see Figure 3.1 B~O), the key action is the reverse radial flow in the gap between the coating rod and the roller. This flow determines the coating thickness . Compared with the flow in the quantitative gap, the importance of the feed on the coating shaft and the reverse rolling of the final film to the web is secondary.

The basic operation of roller coating can be classified according to the type of roller surface curve used, and the schematic diagram of the basic flow of roller coating

For example:

1. Rigidity (the surface is plated with non-deformable hard chrome);

2. Deformable (surface covered with rubber);

3. Carving (the surface is engraved with patterns);

4. Tension web (in the case of single-roll coating).

There is a clear distinction between the physical processes of flow in this primary classification of unit operations. Also, these kinds of operations can be further classified as clockwise or counterclockwise .

This classification approach leads to a relative reduction in the number of basic flow field forms to be divided as described in Fig. 3.2. Each of these flow fields can be subsumed into a few basic operations of known roll coaters. These flow fields are typically characterized by two-dimensional steady laminar flow, for a thousand rigid rods. 3.2 The I?? difference between forward and reverse coating clearly indicated in 2 is very important. For the flexible shaft, the main influence is the interaction between the deformation of the solid and the forces generated in the liquid and solid, so in a sense, the direction of rotation of the cylinder is not important. Gravure stick coating is very different from this. The liquid filled in the small grid or pit is the most, and the day when the sheet takes major role.

The previous definition and classification methods are not very good, but they are only used to classify many phenomena in various stick coating operations. Although some of these basic operating methods have been studied in more detail and are

It has been reported in the literature, but some of them are not well known, and some are still kept as commercial secrets by experimental researchers.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative