German Binder FP series oven Chinese operation manual

1 Product Overview

Binder company, located in Tuttlingen, southwest of Germany, is dedicated to the research and production of laboratory temperature control products. Its patented APT.Line cavity preheating technology makes the temperature in the box very uniform, changing the traditional The thermal system has always been difficult to overcome the upper and lower temperature difference bottleneck. Binder temperature control boxes are widely used in the fields of pharmaceuticals, food, material science, cosmetics, tobacco, microorganisms, chemicals, electronics, etc. There is no doubt that it is one of the largest and professional temperature control box manufacturers in the world.

The range of universal Drying Ovens produced by Binder is of very good quality and its unique advantage lies in its high precision and efficiency, thus guaranteeing safe routine sterilization procedures, fast drying process and high precision heating performance; good price/performance ratio give it a unique advantage. Binder FED series multifunctional hot air circulation oven is a Drying Oven with forced convection and multifunctional controller, which is suitable for heating requirements with frequent temperature changes. Whether for applications that want to maintain better temperature accuracy and ramp rate, or for applications that do not simulate natural environmental conditions through convection, digitally controllable turbines can be used to make the temperature parameters and environmental conditions of the inner chamber well controlled .

1.1 Technical Features

1) Electronically controlled APT.LineTM preheating technology with forced convection;

2) Temperature range: ambient temperature +5°C to 300°C;

3) MP controller, with 2 programs (10 sections each) or switchable to 1 program (20 sections); the interval of each section of a single program can be adjusted to a maximum of 99:59 hours or 999:59 hours, This adjustment applies to all sections of the Program;

4) Integrated weekly program timer with real-time function; ramp function adjustable via program editor;

5) Digital temperature setting with an accuracy of 1°C;

6) The heating rate can be adjusted by the program controller;

7) The fan speed is adjustable, and the measured time timer;

8) Adjust the ventilation volume through the exhaust pipe (diameter 50mm) with ventilation flaps on the back and the ventilation slide plate in the front;

9) Independent adjustable temperature safety device, class 2 (DIN 12880), with visual temperature alarm;

10) RS 422 interface, used for communication software APT-COM@ data control system; or use RS 232/ RS 422 interface converter to convert to printer output port;

11) 2 chrome-plated shelves;

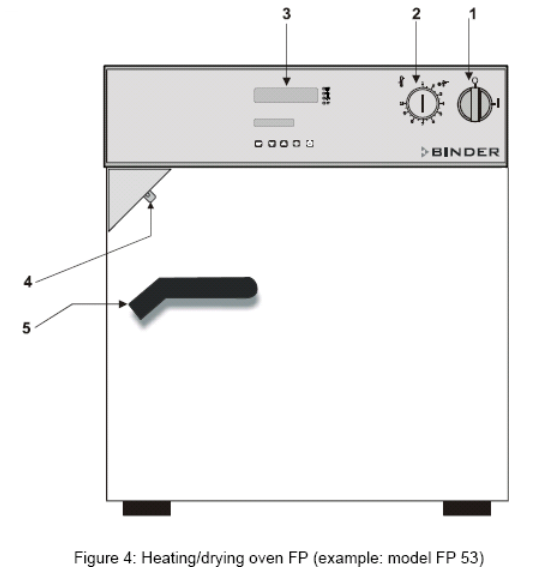

1.2 Appearance

(1) Main switch

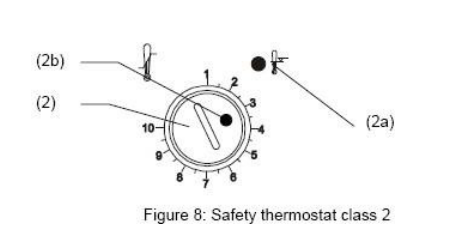

(2) Independent temperature safety device Class2

(3) Program controller RD3

(4) Ventilation slides

(5) handle

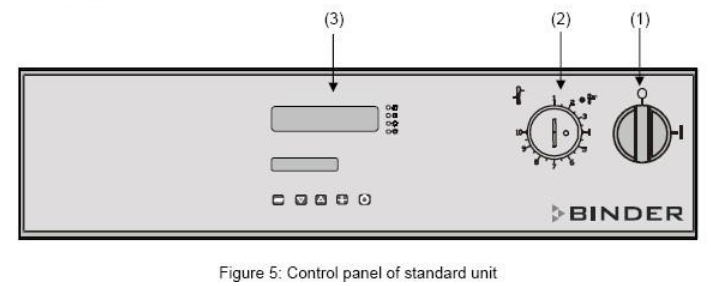

(1) Main switch

(2) Independent temperature safety device Class2

(3) Program controller RD3

2 Installation preparation

The working environment temperature is 5…40°C, the humidity does not exceed 70%RH (no condensation), and the satisfactory condition is below 32°C

Please choose a non-combustible flat surface for the installation site. If more than one oven is placed at the same time, the distance between the ovens should not be less than 16cm

Models below 240L can be stacked up and down, but please place rubber gaskets under the foot pads to prevent the upper oven from slipping

Please check the power supply voltage and specifications, if not, do not connect the power supply, so as not to damage the oven

air exchange

The amount of fresh air exchange can be adjusted using the "ventilation slide" on the panel

Please note: When the "ventilation slide" is fully open, the influence on the accuracy of the inner chamber temperature may reach 5%

Suitable for rapid drying of samples with high humidity or heating of samples prone to large amounts of steam

Please be careful with the exhaust pipe on the back. It will discharge high-temperature gas during operation. Do not touch the human body or flammable substances, so as not to cause maintenance! ! !

3 parameter setting

RD3 controller parameter setting:

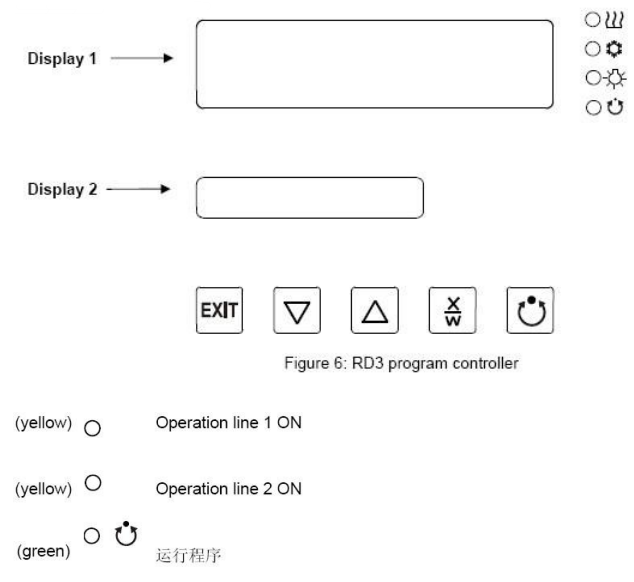

3.1 Program temperature controller

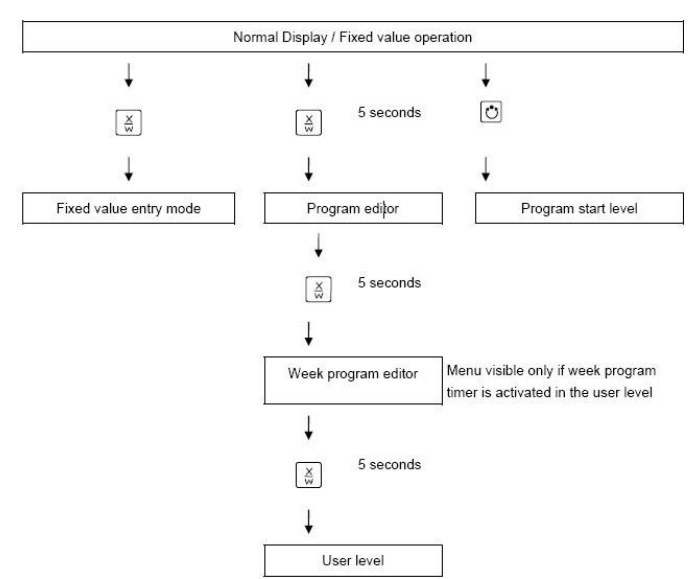

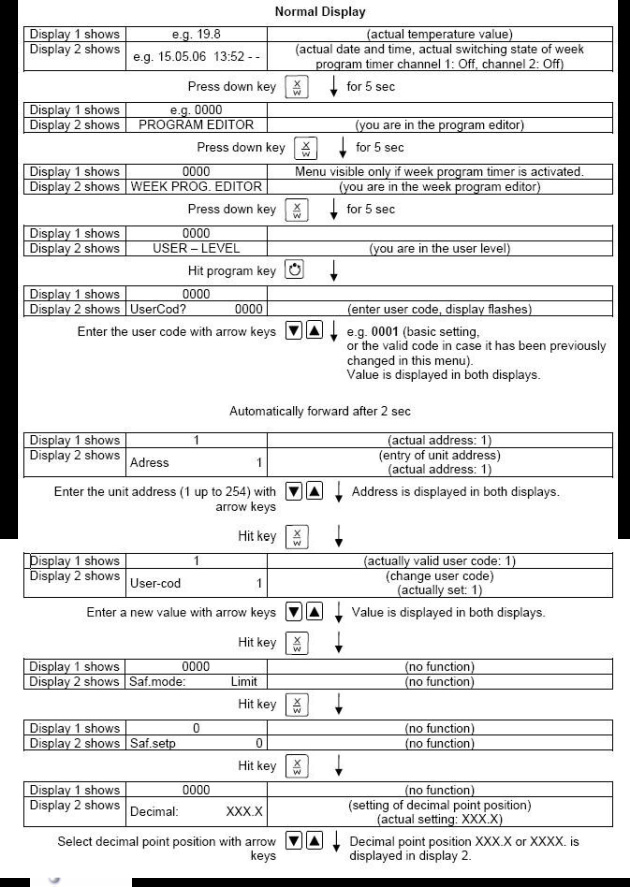

Two 10-step programs or one 20-step program can be programmed. After switching on the main power switch (1), DISPLAY 1 displays the actual temperature and DISPLAY 2 displays the set temperature. The operation interface is as follows:

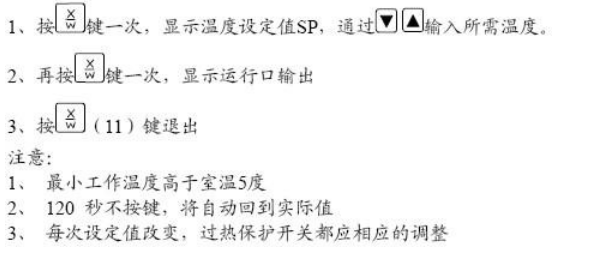

3.2 Temperature setting

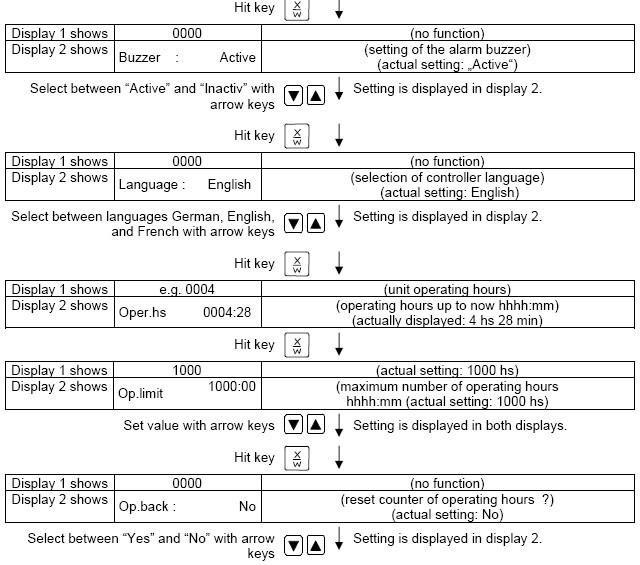

4 User management menu

1. Device address (1-255) Adrees

2. User password (factory setting 0001) user-cod

3. Decimal point position Decimal

4. Alarm status Buzzer

5. Language selectionLanguage

6. Computer running time (only displayed, not set) Oper.hs

7. The maximum running time Op.limit is up to 9999, and it will disappear when the limit is reached

8. Restore the running time Op.back to zero

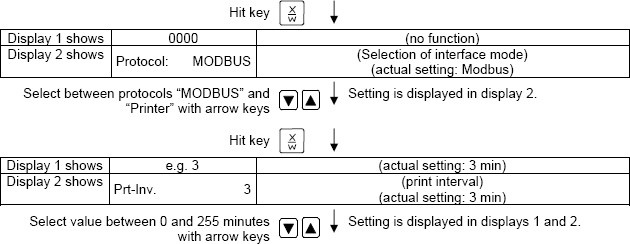

9. Port Protocol Protocol Mobdus can connect to APTCOM software

10. Set the print interval Print interval Prt.-inv

11. Illumination display Disp. LED is always on or off after 300 seconds by automatic control

12. Program type selection PrgSelec

13. The maximum duration of the step Prg.Time 99h59min 999h59min

14. Deviation limit range Tol.band setting 0 means the function is off

15. Activate or deactivate the weekly program counter (Prog.Clk)

16. Set time

5 temperature control safety device

"Temperature control safety device" is a mechanical temperature controller independent of the electronic temperature control device. When the electronic controller loses its function, it can provide double protection to protect the environment safety of the oven, samples, and operators from damage due to high temperature. Cause accidental disasters, in line with DIN 12880 class2 norms

5.1 Setting method

1. Please set the temperature of the electronic controller first, and wait for enough time to allow the inner cavity temperature to stabilize

2. Confirm that the "inner cavity temperature" has reached the "set temperature" before adjustment can be made

3. Use a 1 yuan coin to turn the knob clockwise to the end (position 10 on the scale), this point is to protect the oven equipment from overheating damage (to prevent misuse, the knob is very tight and needs to be turned hard, this is normal phenomenon)

4. Then, slowly turn the knob back in the "counterclockwise direction" until the "temperature warning light" is on and the "short circuit switch" trips, the second is the maximum temperature limit

5. In order to make the oven reach the set temperature smoothly, so as not to jump out of the machine in advance before reaching the working temperature, and then rotate to the "clockwise direction" to increase a scale, which is a good set point

5.2 Shutdown processing

1. When the machine is abnormally tripped, the "temperature warning light" is on, and the "circuit breaker" is tripped. Please immediately cut off the power (unplug the plug) and remove the heated sample to ensure safety.

2. Is the set point of the temperature control safety device lower than that of the electronic temperature control device? Is the electronic controller defective? Please contact Tegent Technology Co., Ltd. professional engineers immediately

3. After troubleshooting, reconnect the power supply and press the "break switch" to restart the operation

4. When the "break switch" trips, the heater, fan, electronic controller, etc. cannot be used

5. The 1…10 scale of the knob, relatively represents the range of 30…320°C (for reference only, not as a set value)

6. The scale is for reference only and does not represent a certain temperature range. According to the above method, the actual operation and adjustment

7. When the knob is turned to the extreme end, this safety protection device implements the overheating function protection of the box body.

When the knob is turned slightly higher than the set temperature, the device implements overheating protection for baked items in the box

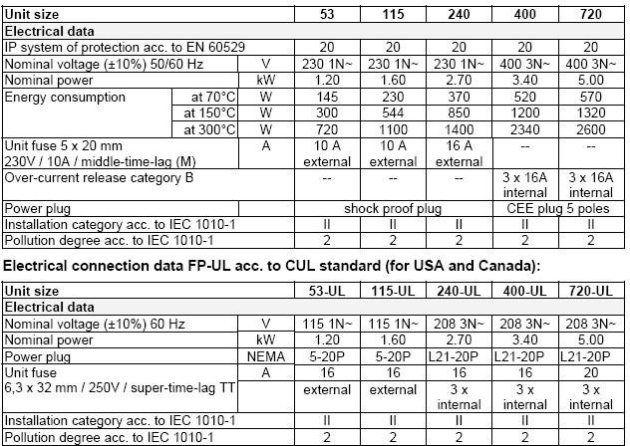

6 Technical parameters

- 1Principle, application and selection of Electric Oven

- 2Principle, application and selection of Electric Oven

- 3Principle, application and selection of ozone sterilizing oven

- 4Principle, application and selection of tunnel oven

- 5Working principle and application analysis of laboratory oven

- 6Hot Air Oven FAQ and its solution

- 7Precision oven FAQ and its solution

- 8Oven FAQ and its solution

- 9How to calibrate the Drying Oven?