YT-YSK series compression testing machine operation instructions

YT-YSKN series compressive testing machine is a multi-functional, high-precision carton quality inspection equipment, mainly used for compressive strength testing machine of various corrugated cartons.

This experimental machine adopts a professional mechanical structure of double screw and double guide column, controlled by stepping motor, with high parallelism, good stability and high measurement accuracy.

This testing machine has the functions of various parameter testing, display, memory, statistics and printing included in the standard. It has the function of data processing, can directly obtain the statistical results of various data, has the functions of automatic reset and fault diagnosis, and is easy to operate.

2. Installation and placement and precautions

2.1 . The power supply used in this experiment machine is AC 220V power supply.

2.2 . There must be no equipment with strong magnetic interference around the testing machine.

2.3 . The testing machine needs to be placed in a stable and vibration-free place.

2.4 . Considering the safety of transportation , the four shock absorbers and the control box of the testing machine have been dismantled from the test machine , and four buffer cushions are added at the middle points of the upper and lower pressure plates . The user needs to install the shock absorbers and the control box before use. Control box , then plug in the power supply under the condition of ensuring that the power wiring is correct , turn on the power supply on the testing machine and the control box , press the up button on the board to move the upper platen upward , remove the four buffer pads and press the stop button to stop .

3. Product structure

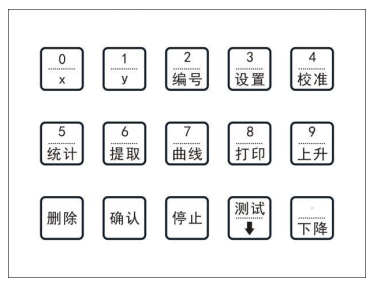

3.1, 0-9: used to input data or options, etc.;

3.2 , . : used to enter a decimal point ;

3.3 , x : used for x coordinate setting ;

3.4, y: used for y coordinate setting;

3.5 . Confirmation : used for input approval ;

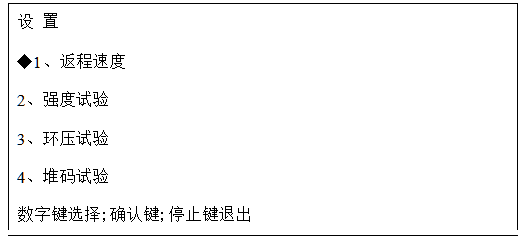

3.6 , setting :

Set return speed

Set the strength test mode ;

Set the ring pressure test mode and set the fixed value parameters ;

Set the stacking test mode and set the stacking parameters;

3.7. Calibration: used for system time calibration, pressure calibration and zero point calibration;

3.8. Number: number setting;

3.9. Curve: switch between curve mode and digital mode;

3.10. Statistics: used in the strength test mode, statistical test results (average, maximum, minimum, standard deviation);

3.11. Print: used to print the test and statistical data;

3.12. Extraction: used to view the measured data; then press the button to view the next measurement key (the speed is the pressurization speed);

3.13. Delete: used to delete the current invalid data; double-click to clear the measured data;

3.14. Rising: the pressing plate runs upwards (the speed is the same as the return speed);

3.15, descending: the pressure plate runs downwards (the speed is the same as the return speed);

3.16. Test: Start measurement;

3.17. Stop: stop the measurement key or stop the platen operation test data.

4. Operation guide

4.1 Start up

1 ) Insert the main power plug of the device into the power socket.

2 ) Turn on the power switch of the device.

3) The program starts, and the startup interface is displayed as shown in the figure below.

4) After five seconds, the system enters the last test working mode interface (hereinafter referred to as the pre-working interface).

注意:工作界面随测试的工作模式不同而略有改变,具体界面见工作模式设置。

4.2 工作模式

1)按设置键,进入以下设置界面:

2)选择“强度试验”或“环压试验”或“堆码试验”可进入相应工作模式界面。

3)参数设置完后按确认键进入相应的工作模式界面。

4.3 试样放置

按上升或下降键,使上压板上下移动到合适位置(恰好可以放入试样),再按下停止键使压板停止运动,将试样放在下压板的正中间。

注意;由于在快速运动中紧急停止时会有过冲现象,所以需要提前按停止键,使上压板停止运动。

4.4 单次测试步骤

1)按下测试键,上压板开始上压,窗口实时显示力值,当力值达到220N 时开始显示变形量,当测试过程中可随时按停止键终止测试。

2)试样压溃或达到设定值时,测试结束,上压板自动返回起始点,并显示实际测试结果。

3)此时可按打印键打印当前测试结果

4.5 删除本次无效数据

在测试完毕进入下一个预工作界面时,可顺序按提取键、删除键将此次测试数据删除,不计入数据统计之列。

4.6 当次数据查询或打印

在测试完毕进入下一预工作界面时,可按提取键提取当次测试结果,若需打印可按打印键打印此次数据。

4.7 多次测量步骤

重复步骤 5.5、5.6 做同组其他试样,最多可记忆 10 次测量数据。

当数据超过 10 次时,替换最后一次(第十次)。依次测试时,测量次数加一,批次(编号)不变。

4.8 数据统计打印

当测完同规格所有试样后,可按统计键显示统计结果。统计结果为力值和变形量的最大值、平均值、最小值和标准偏差。数据统计后测量次数重新变为 1,编号自动加一。

此时按打印键可打印统计结果。

注意:环压试验、堆码试验无统计功能。做下组测试之前,先双击删除键清除已测数据。

4.9 关机

1)按下试验机面板的电源开关,切断该设备的交流电源。

2)拔下电源插座。

4.10 调零、校准、检定与保护控制

(一)、调零

当测试时,上压板没有受力,而力值显示不为零时,按校准键,选择压力校准,按清零键进行力值调零。

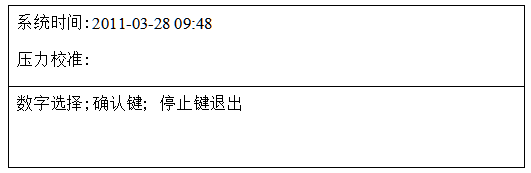

(二)、系统时间校准,力值校准、检定

a、当打印时,打印时间不正确时,可进行时间校准,按校准键,按确认键,再按数字键输入时间,再按确认键退出。

b、当实际静态力值实际不符时,为保证测量的准确性需要进行相应的校准。按校准键如上图所示,再按 2 键,按确认键,如下图所示:

上压板不受外力时(上下压板之间不放试样,上压板离开下压板),当前力值不为零时,双击删除键键调零。上下压板之间并且在下压板中间位置放置检定压力计,然后按下降键,当压力计显示为 3000N 附近是按停止键。观察仪器当前力值和检定压力计之间的误差,如误差小于 1%时,不需要校准,按确认键,再按停止键退出,否则进行下一步校准。

注意:非专业计量检定人员不允许做以下校准步骤!

Calibration: Do as in 2.2, when the error is greater than 1%, press the number keys to input the value of the calibration pressure gauge , and press the confirmation key, enter the password: 34512, and then press the confirmation key. Enter the calibration interface again , press the test button (raise the pressure plate), and press the stop button halfway to observe the pressure error of multiple points. If the error is still greater than 1%, the calibration steps can be repeated.

(3) Protection and control

a. During the test, if the force value exceeds the full scale, the upper platen will stop automatically. At this time , you can press the up button to release the pressure on the upper platen.

b. During the test, when the upper platen hits the upper and lower limit bumps, the upper platen stops moving immediately, and at this time, press the up or down button to leave the limit position.

6. Maintenance

6.1. After the test, the power should be turned off in time and the workbench should be cleaned to keep it clean and dust-free.

6.2. When the instrument is not used for a long time, it should be covered with a dust cover.

6.3 . Regularly wipe the screw rod and guide post with a clean dry cloth , apply lubricant after cleaning , and start the machine to walk back and forth for more than 3 times ( the lubricant can be general lubricating oil , and it is recommended to use lithium- based grease ) . This work is generally carried out once a quarter , and the column cover needs to be removed during maintenance.

6.4 At ordinary times, more attention should be paid to whether there is any abnormal sound of the parts during the mechanical movement , and whether the solid parts are loose. And timely maintenance.