Scraper Fineness Meter selection guide

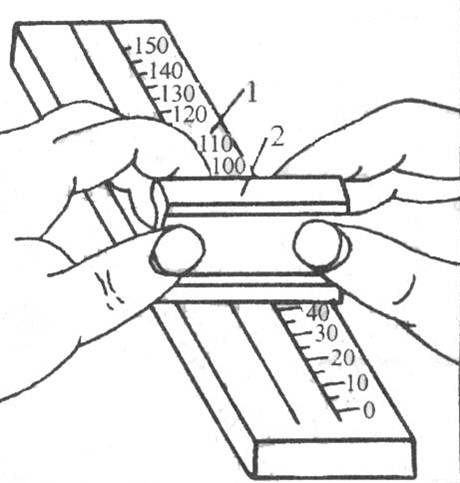

The scraper Fineness Meter is mainly a type of testing instrument used in the laboratory to evaluate the fineness of particles such as pigments, Printing inks, paints, tinters, etc. It consists of two parts: a scraper and a scraper. By engraving one or two grooves from deep to shallow at an oblique angle on the scraper, with a scraper with high straightness requirements, the test slurry is scraped down from deep to shallow, and the actual particle fineness is observed by the naked eye. This is a physical principle and is relatively simple.

It should be emphasized that from thousands of users who consulted Fineness gauge from nbchao, we found that about 70% of users have the following three questions when choosing a scraper fineness gauge:

1) There is an estimated fineness, but I don't know which range to choose

2) What is the difference between one path and 2 paths scraper Fineness Meters?

3) What is the difference between expensive and cheap?

Before answering these questions, let me sort out the hundreds of Fineness gauge specifications from nbchao:

The following table is the main type of scraper Fineness Meter

| Distinguished by groove style | 1 path (standard, small one path, large one path) 2 paths (standard, small 2 paths, large 2 paths) |

| Distinguish by range | 0~15μm 0~25μm 0~50μm 0~100μm 0~150μm 0~250μm 0~500μm |

| Distinguish by resolution | 1μm、1.25μm、2μm、2.5μm、5μm |

Well, back to the question itself, how should the scraper Fineness Meter be selected?

Then specifically we answer most of the Customer relationship questions:

1) There is an estimated fineness, but I don't know which range to choose

We have referred to most domestic and foreign standards. In general, most of the descriptions are for the application of a scraper Fineness Meter with a range of 50μm when the fineness is 30μm and below. A scraper Fineness Meter with a range of 100μm should be applied when 31~ 70μm, and a scraper Fineness Meter with a range of 150μm should be applied when it is above 70μm. Of course, you will find that there are no candidates for 15μm, 25μm and 250μm and 500μm? No! This is just to provide you with a reference for selection. The logic of choosing a scraper fineness gauge is that the most satisfactory state is to estimate the possible measured target fineness as much as possible in the middle of the overall range of the Fineness gauge, which is convenient for observation. The deepest and shallowest parts of the groove may be caused by manual errors and other reasons (this is determined by the principle of scraping), so such a selection method is recommended.

2) What is the difference between one path and 2 paths scraper Fineness Meters?

Laboratory personnel generally have a clear understanding of "reproducibility" and "reproducibility". In general, the measurement data at different times and in different environments may fluctuate. In particular, the scraper Fineness Meter is mainly operated by hand, and the fineness will change differently at different temperatures, and often this kind of experiment requires multiple weighted averages. At this time, the advantages of 2 paths are reflected. At the same time, in the same environment, the same operator scrapes the sample at the same speed and pressure, and the data comparison between the two greatly improves the detection efficiency and data accuracy of the experimenter. Therefore, the 2 paths Fineness gauge is recommended if conditions permit.

3) What is the difference between expensive and cheap?

The editor does not rely on bragging. There are at least more than 30 Fineness gauges of different brands that have been used in his hands. What is the difference between them? From the perspective of craftsmanship, this is really not difficult to do. But often the mercenary nature of merchants is always very good in business. The value of measuring expensive and cheap is also implicit in this truth. We know that when the scraper scrapes the sample on the scraper, in addition to the precise depth of the groove, the flatness of the surface of the scraper and the linearity of the scraper should also be guaranteed, otherwise the result of scraping out can only deceive yourself. In order to make the groove, the surface of the scraper, and the scraper meet the requirements, this process needs to be processed repeatedly → inspection → return to the factory → re-inspection →... In this way, the cycle continues, and finally a piece of scraper fineness that meets the requirements is obtained. Cheap is cheap because many manufacturers only need to reduce their pursuit of craftsmanship in order to make their own costs lower, more competitive prices, and higher profits, so a lot of labor costs will be recovered. On the contrary, if you want to make an accurate Fineness gauge that can pass Measurement, this cost cannot be measured by the price of a steel plate. What's more, the material of the steel plate is also good or bad! The editor has seen a Coating factory use the scraper Fineness Meter to rust in less than a few days. I believe that users should be able to understand.

Therefore, nbchao, as a Coating testing instrument platform that always follows fairness and transparency, reminds the majority of users that although we pursue cost performance when purchasing scraper fineness timing, please don't take cost performance as price ratio. Such a one-sided evaluation standard will eventually make you lose more than you gain.

Author: NBchao. Com Mall

2018/9/5

Reprinting is strictly prohibited

- 1Coating fineness of ground - Fineness gauge

- 2Coating fineness test method and influencing factors

- 3Fineness Detection of Precious Metal Slurry in Microelectronic Technology with Fineness Meter

- 4Inks Fineness gauge principle results and usage introduction

- 5Basic Principle and Application Analysis of Coating Fineness Scraper

- 6Coating Fineness Determination and Its Importance

- 7Detection Steps of Coating Fineness and Operation Method of Ground Gauge

- 8Fineness gauge detection principle

- 9How to use Fineness of Ground Gauge to measure colorants?