The specific operation method of cable light LX-300 thermostatic circulator

Suoguang LX-300 constant temperature circulator uses a compressor for refrigeration, and then conducts heat exchange with water to reduce the temperature of the water and sends it out through a Circulating Chiller. At the same time, the temperature controller is used for temperature control, which has three functions of constant temperature, cooling and circulation. Constant temperature circulators are mainly used in analytical instruments, vacuum acquisition, medical and industrial equipment, etc.

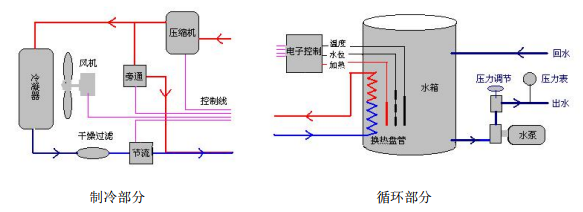

working principle

The cold water produced by this machine and the equipment that needs temperature control form a closed circulation waterway. Heat generated by equipment or instruments is transferred from the equipment by a liquid carrier. The heat is dissipated outside the machine through the refrigerator, so as to ensure that the equipment works within the normal temperature range. At the same time, special media are generally used in the closed circulating waterway, which effectively solves the problems of fouling and foreign matter blockage in the traditional open circuit circulating system, thereby greatly reducing the maintenance amount and failure rate of the circulating waterway. The working principle is shown in the figure below:

Instructions

1. This machine requires an external closed loop.

2. In order to avoid the possibility of incorrect or reverse connection of the water inlet and outlet, which may affect the cooling effect or cause accidents that should not happen, please be sure to check the direction of the cooling water path of the equipment to be cooled, or read carefully. Instructions for equipment requiring cooling.

3. Pipeline connection: There is a water outlet interface and a return water interface on the rear upper part of the machine, which are respectively connected to the equipment that needs to be cooled. The water outlet interface of the machine is connected to the water inlet of the equipment that needs to be cooled. It is connected to the water outlet of the equipment requiring cooling. The connection between the two devices requires a pressure-resistant hose to prevent water leakage and pipe rupture.

4. Adding water: The machine is forbidden to run without water. The water filling port of the Water Tank is set on the top of the machine. Pick up the top cover and unscrew the water filling port to add water to the Water Tank. Generally, special media such as distilled water, purified water, and light oil are used. There is a "water level" observation window on the front panel of the machine. Generally, add water to the upper limit of the "water level" indication window (about 2cm from the upper edge of the window). When the external circulation waterway is long and takes up a lot of circulating medium, please pay attention to observe the water level when running the machine for the first time, and replenish the circulating fluid in time to ensure the normal water level of the machine.

5. Operation of the control panel: The main power switch of the machine is at the rear of the machine, and the functions of the keys on the panel are as follows:

POWER meter power switch: press this button to control the meter to start working, the temperature display window (PV) shows the actual measured temperature of the Water Tank liquid, (SV) shows the set target temperature.

COOL refrigeration switch: press this button to start the refrigeration unit, and the refrigerator starts to work (when the temperature of the Water Tank reaches 40°C, the refrigeration compressor stops working by itself). It is forbidden to restart the compressor within three minutes after this switch is turned off.

PUMP circulation switch: Press this key to start the circulation pump, and the constant temperature cooling water will be sent out through the circulation pump.

Function key: Press this key once, the value of (SV) will flash, adjust its value through the shift key, increase key, and decrease key, press this key again to confirm, the value stops flashing, and the target temperature setting is completed.

Shift key: Press this key once, the cursor moves once, and the digit to be changed is selected.

Increase key: increase the value of the selected digit.

Decrease key: Decrease the value of the selected digit.

PV: actual measured temperature .

SV: Set target temperature.

OUT: heating indicator light.

AUTO: Auto-tuning indicator.

OVER and LEVEL alternate indications.

Note: Press and hold the function key for 3 seconds, the meter enters the state of intelligent parameter modification; press and hold the function key for 3 seconds to exit this state. Please users generally do not modify the internal parameters, so as not to cause control confusion. Factory parameters (for reference only):

First alarm AL-1=10.0 Self-tuning At=OFF Temperature deviation PU-b=-4.0 Set temperature upper limit P-SH=40.0 Set temperature lower limit P-SL=5.0

4. Application of self-tuning (intelligent control) function: After the machine works normally, press and hold the key for 3 seconds, and the instrument enters the state of intelligent parameter modification: click the button, find the AT setting, and then click the button to modify the OFF setting of the AT setting parameter After it is ON, press and hold the key for 3 seconds at last to start the self-tuning function, and the meter display returns to the normal PV/SV display. At this time, the AT light on the panel flickers, and the SV display window displays -AT- intermittently. After the auto-tuning is finished, the meter will automatically return to normal display. During the running of auto-tuning, the auto-tuning state cannot be forcibly exited.

Description of the front panel of the machine

The front panel of the machine is mainly composed of control instruments and a water pressure gauge. Power switch POWER: Control the power switch on the front panel. Press this key to control the meter to start working, the (PV) window displays the actual measured temperature of the liquid in the temperature tank, and (SV) displays the set target temperature. Circulation switch PUMP: Turn on the circulation switch, the circulation pump will start automatically, and the constant temperature cooling water will be sent out of the instrument through the circulation pump. Refrigeration switch COOL: After confirming that the Circulating Chiller is working normally, turn on the refrigeration switch, start the refrigeration unit, and start refrigeration. Water pressure gauge: The water pressure gauge can read the pressure of circulating water in real time.

Description of the rear panel of the machine

Main power switch: on the upper right side of the rear of the machine. Water outlet: At the rear of the machine, the circulating water is sent out, and a filter sewage device is optional. Water return port: at the back of the machine, the circulating water returns, and the size of the water nozzle can be configured according to user requirements. Drain port: at the rear of the machine, unplug the drain plug to drain the water in the Water Tank.

Precautions for use

1. Avoid direct sunlight on the instrument.

2. The instrument should be placed in an environment where the temperature is lower than 35°C, there is no corrosive gas, and the relative humidity is lower than 80%.

3. When in use, the surrounding area of the instrument should be well ventilated, and the distance from the wall or obstacles should not be less than 30cm.

4. The instrument needs to use an independent power supply (AC 220V, 50Hz, 10A) and be properly grounded.

5. Before moving the instrument, stop the machine and release the medium. During transportation, the instrument must be carried upright, and if necessary, the inclination angle shall not exceed 45 degrees.

6. The refrigeration system should not be started and stopped frequently, otherwise the compressor may be damaged.

- 1Application of Julabo Heating and Refrigeration Circulator in Petrochemical Industry

- 2Application of Julabo Heating and Refrigeration Circulator in Automotive Industry

- 3Application of Julabo Heating and Refrigeration Circulator in Semiconductor, Photovoltaic Photovoltaic Industry

- 4Application of Julabo Oscillating Bath in Pharmaceutical and Medical Industry

- 5Application of Julabo Heating and Refrigeration Circulator in Food Industry