MOLFOG10A Conditioning machine special pure water machine instruction manual

Equipment Diagram

1.1 Equipment Appearance

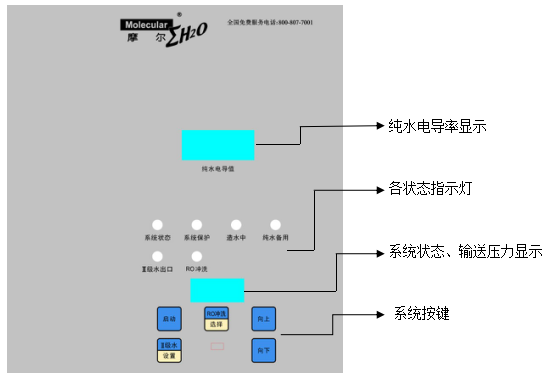

1.2 Equipment operation panel

2 Introduction to the basic principle of the equipment

PP fiber filter element: unique outer loose and inner tight structure, can effectively remove suspended matter, sediment, and particulate impurities above 5micron or 1micron (determined according to the pore size of the PP fiber filter element) in the water source; effective activated carbon filter element: has a very strong Adsorption and filtration performance can effectively remove impurities such as color, odor and organic matter in distilled water.

Activated carbon filtration: chemical adsorption to remove chlorine, organic adsorption to remove soluble organic matter. Because the reverse osmosis membrane is sensitive to chlorine and soluble organic matter, carbon columns are often placed in front of the RO membrane to remove these substances.

Reverse Osmosis Membrane: Osmosis is the flow of water through a semi-permeable membrane from the low concentration side to the high concentration side. If a high-pressure pump is used to provide a high-concentration solution with a pressure greater than the osmotic pressure difference, water molecules will be forced to pass through the semi-permeable membrane to the low-concentration side. This step is called reverse osmosis. Reverse osmosis can filter out 90%-99% of most pollutants. Because of its superior purification efficiency, reverse osmosis is a very effective technology for water purification systems. Because reverse osmosis removes most of the contaminants, it is often used as a pretreatment method, which can significantly extend the life of the deionization column. Reverse osmosis treated water is high quality pre-purified water suitable for routine use in many laboratories. The reverse osmosis membrane made in the United States can effectively remove various salt ions, organic matter, bacteria, and viruses in the water, and the total salt removal rate can reach more than 99%, and can remove organic matter with a molecular weight greater than 300dalton;

Purification column: US ultra-pure water special ion exchange resin and special flow path design, high ultra-purification efficiency, can effectively remove trace ionic substances in water.

The operation control of the machine adopts intelligent microcomputer control, touch the button, and has the operation status display, and the water quality online monitoring, fully realizes the man-machine dialogue.

3 Mole water purifier working conditions

Operating Voltage | 220V±10%/50Hz, with reliable grounding |

power | 200W |

raw water temperature | 5-40℃ |

tap water pressure | 0.15-0.25Mpa (if it is higher than 0.25 Mpa, the customer needs to take decompression measures, otherwise it is prone to overpressure damage and water leakage; if it is lower than 0.1 Mpa, the equipment will alarm and shut down, and a booster pump needs to be added) |

working environment | The installation site should ensure a ventilated and dry environment, and the temperature should be between 5-30°C; especially in northern areas, prevent the instrument from freezing in winter, as the water in the instrument will freeze and cause the instrument to be effectively damaged; do not place the equipment in a place with high acidity big environment |

4 Water purifier equipment installation steps

4.1 Requirements for installation conditions

4.1.1 The equipment should be installed in a ventilated and dry environment as much as possible.

4.1.2进、排水管规格应满足纯水器配套接口要求,且应距离主机2米范围内。

4.1.3设备放置稳定、可靠、位置正确。

★ 4.1.4设备旁应设有排水沟或排水槽、以及围堰。

4.1.5系统电源、电线配备合乎设计要求。

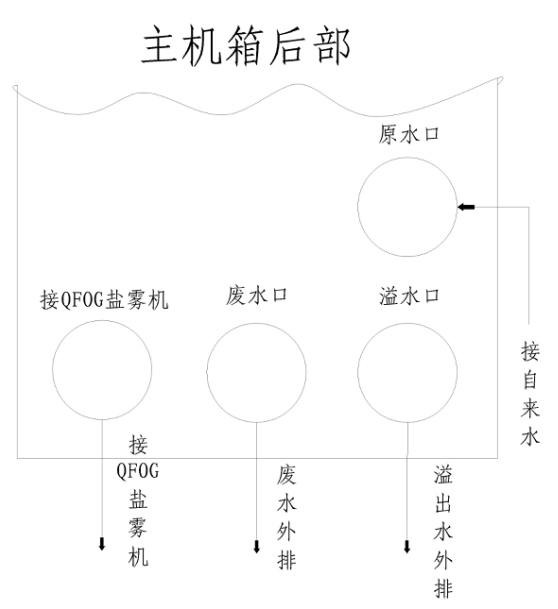

4.2 安装

4.2.1检查机器的装箱单与实际零件相符合;

4.2.2请断开水源及电源;

4.2.3请将配件中的金属接头和水龙头与客户供水处连接好,再用2分白色PE管将机器后部原水口与水龙头出口处连接好;

4.2.4从机器后部的废水口接2分白色PE管至水槽并插入下水管内;插入长度约0.5米;

4.2.5从机器后部的溢水口接白色PE管至水槽并插入下水管内;插入长度约0.5米;

4.2.6从机器后部的“接QFOG盐雾机”接口用3分白色PE管接至盐雾机;

4.2.7要求安装后整洁,清爽。

4.2.8将机器的电源插头插入符合安装标准的220V插座。

4.3设备安装示意图

主机箱后部的管路连接示意

5 设备操作维护标准程序

5 .1 功能说明

5.1.1工作模式选择

短接电路板后的K2,系统工作于压力控制模式,数码显示压力值(单位公斤)。

断开电路板后的K2,系统工作于定时间取水模式,数码显示时间(单位S)。

E01:机器进水压力低,机器不能正常制水。

E02:纯水箱纯水液位低于低液位开关,机器不能取水。

5.1.2设置

在设置状态时,以下按键是复用的。

正常工作时 | 设置时功能 | 说明 |

三级键/设置 | 设置 | 待机时,长按3秒进入设置 |

RO冲洗键/选择 | 选择 | 压力控制模式时选择要设置的高、低压力控制点,高H xx、低L xx。(注意:此操作第一次调节好后,以后不得随意去调节,否则会引起输送故障) 定时间取水模式时选择欲修改的百、十、个位 |

向上 | 增加 | 增加数字 |

向下 | 减少 | 减少数字 |

当系统处于待机状态时,长按设置按键3秒后,进入设置状态,按选择键选择要修改的数据项,按增加或减少修改数据。可按下待机键或再次按设置键退出设置。

5.2 指示灯说明

指示灯 | 状态 | 说明 |

启动灯 | 红 | 待机 |

绿 | 工作、设置 | |

报警 | 1秒-1秒闪烁 | 进水压力低或进水压力开关故障 |

0.5秒-0.5秒闪烁 | 中或高液位开关故障 | |

0.3秒-0.3秒闪烁 | 水位低于低液位或低液位开关故障 | |

三级取水 | 闪烁 | 三级定时间取水且窗口显示三级取水剩余时间 |

常亮 | 一级随机取水,或一、三级同时处于定时间取水但窗口显示处于一级取水剩余时间显示的时段。 | |

冲洗 | 闪烁 | 处于上电冲洗、定时冲洗或造水后冲洗等程序性自动冲洗。 |

常亮 | RO人工冲洗 | |

纯水备用 | 闪烁 | 水箱水位在中液位和高液位之间 |

常亮 | 水箱水位到达高液位 | |

灭 | 水箱水位低于中液位 | |

造水 | 亮 | 造水状态 |

5.3 启动

打开自来水阀门后,打开机器背部的电源开关,按下控制面板上启动键,“系统状态”灯亮;设备开始进入开机自动冲洗状态,“RO冲洗”灯闪烁;约3分钟后,如果纯水未满水,会自动切换到造水状态,“造水中”灯亮;反之,则“纯水备用”灯亮。

5.4 冲洗

5.4.1 上电自动冲洗。当按下启动按键后自动自行上电冲洗功能,可由RO冲洗键中断上电自动冲洗进入RO人工冲洗。

5.4.2 造水后自动冲洗。当造水水满后,自动执行造水后冲洗,可由RO冲洗键中断造水后自动冲洗进入RO人工冲洗。

5.4.3 定时冲洗。当累计造水超过两小时后,自动执行2分钟定时自动冲洗,定时自动冲洗未完成时可由RO人工冲洗中断进入RO人工冲洗,但不能立即消除系统的定时冲洗记忆,当中断RO人工冲洗后还会执行定时冲洗。但当执行上电冲洗或RO人工冲洗时间超过2分钟后,可消除系统中定时冲洗的记忆。

5.4.4 RO人工冲洗。当按下RO键,执行人工冲洗,再次按下RO按键中断RO人工冲洗,否则5分钟后自动结束冲洗。

上电冲洗、定时冲洗、造水后冲洗属于系统自动执行的冲洗动作,当执行自动冲洗时,冲洗指示灯闪烁指示,当自行RO人工冲洗时,冲洗指示灯常亮。

5.5 造水

当系统检测到水箱水位在中液位下时,启动造水,当水位到达高液位时,停止造水。但当虽然检测到中液位无水而高液位水满时(液位开关有故障),或检测到进水压力低时,则不会执行造水动作,如果正在执行造水动作也会立即中断,系统会进入报警状态(见报警)。

5.6 取水

当低液位有水时,按下三级取水按键,执行三级取水功能,再次按下相应按键,停止相应动作。

当电路板后面的K2处于断开状态时,系统工作于定时间取水模式。该模式下,如用户设定的定时间值不为0,取水动作执行到设定的时间后自动停止,如用户设定的定时间值为0(显示―――),则关闭定时功能。

5.7 压力控制

当选压力控制模式时,显示窗口显示压力桶压力。当水箱低液位有水10分钟后或当中液位有水时,系统判断压力值,当压力值低于设定的压力低限时,系统输出控制信号驱动外部故态继电器,反之,当压力高于等于设定的压力高限时,系统关闭该驱动输出。

5.8 报警及保护

5.8.1 当系统检测到进水压力低时,不能执行或中断执行的造水动作,系统发出1s-1s间隔的声光报警。按任意键或一分钟后自动消除报警声音。

5.8.2 当系统检测到中液位无水高液位水满时,不能执行或中断执行的造水动作,系统发出0.5s-0.5s间隔的声光报警。按任意键或一分钟后自动消除报警声音。

当系统检测到低液位无水时,不能执行取水、循环或中断当前的取水、循环动作,系统发出0.3s-2s间隔的声光报警。按任意键或一分钟后自动消除报警声音。

5.9 水质调节

当电导表显示电导值远大于15μs/cm时,需调小机箱内部“纯水手动针阀”,当“纯水手动针阀”调节至最小后,电导值仍远大于15μs/cm,此时需更换纯化柱mp2,以满足老化机进水水质要求;当电导表显示电导值小于15μs/cm时,需调大机箱内部“纯水调节阀”。

6 耗材更换操作步骤

先关闭自来水进水阀,当低压开关报警后关闭电源开关,这样可减少滤芯中的余水量,便于耗材更换,再打开机箱两侧活动门,可利用简单工具进行设备的更换:

6.1 Primary preprocessor filter element: Use a belt wrench to hold the cylinder marked with the primary preprocessor filter element (PP filter element) and rotate counterclockwise, slowly unscrew the primary preprocessor filter cylinder, and remove the cylinder. Take out the inner filter element, clean the cylinder body (please pay attention not to remove the black rubber ring in the cylinder body when cleaning), put the new stage preprocessor filter element (PP filter element) back into the cylinder body, and pay attention to the center hole of the PP filter element. Align with the center hole of the cylinder body, then install the cylinder body on the fixed end cap interface, hold the cylinder body with a belt wrench, turn it clockwise and tighten it, refer to schematic diagram 1 and diagram 2.

6.2 Secondary and fourth-stage preprocessor filter elements: the replacement of the second-stage (activated carbon filter element) and fourth-stage (fine filter element) preprocessor filter element is the same as that of the first-stage preprocessor filter element (please note the black rubber gasket on the activated carbon do not drop).

6.3 Replacement of No. Molp mp2 purification column: Loosen the hoop that fixes the purification column and the PE tube quick-plug connectors at both ends of the purification column, and replace it with a new purification column. When replacing, pay attention to the fast plug-in interface of the PE pipe to be inserted tightly, and fasten it with the blue clip.

6.4 Replacement of reverse osmosis membrane: understand the water inlet and outlet directions of the three interfaces of the membrane, and pay special attention not to confuse the pure water port with the waste water port. Then loosen the hoop or single clip that fixes the membrane, connect the newly arrived reverse osmosis membrane, connect the corresponding interface pipes, and fasten them with blue clips.

Notice:

①. Install in order and seat according to the number.

②. All parts should be tightened and locked in place, otherwise the equipment is prone to water leakage during the water production process.

③ After installation, turn on the power supply for flushing and operation. If water leakage is found, please tighten the joint in time to confirm that there is no water leakage and the water quality meets the standard before use.

7 Judgment and method of consumable replacement

name | Model Specifications | Standard quantity | Replacement cycle (The quality of tap water is different, and the replacement cycle is different) | Measure to judge |

Primary pretreatment filter | Molcot 10 | 1 stick | 1-2 months | Observe through the transparent cylinder that the color of the filter element turns dark yellow and can be replaced |

Secondary pretreatment filter | Molgac10 | 1 stick | 4-6 months | If the local water quality is poor and there is a lot of floating powder, the replacement time should be shortened. |

Four-stage pretreatment filter | Molpp10 | 1 stick | 4-6 months | Observe the color of the filter element through the cylinder and change it to darker yellow to replace it |

Reverse osmosis membrane | 2 sticks | About 1 year, 3 at the same time | Judging by the conductivity displayed on the machine, when the conductivity is greater than 15μs/cm (no more than 20μs), it needs to be replaced. | |

Purification column | Molp mp2 | 1 stick | ||

Note: The 15μs/cm determined in the secondary reverse osmosis membrane and the purification column means that when the "pure water manual needle valve" is adjusted to the minimum, the conductivity value is still far greater than 15μs/cm, and it needs to be replaced at this time | ||||

- 1How to clean the laboratory water purifier?

- 2What are the criteria for selecting laboratory purified water equipment?

- 3Ultra-pure water machine - triple filter element replacement method

- 4What should I do if the solenoid valve of the experimental ultra-pure water machine encounters these failures?

- 5Detailed purchase method of laboratory ultra-pure water machine [dry goods]

- 6What is the difference between "water intake flow" and "water intake flow rate" in laboratory ultrapure water machines?

- 7How to choose the right high-quality experimental ultra-pure water machine?

- 8 Why do you need to replace the consumables of the ultra-pure water machine regularly?

- 9What is the difference between ordinary pure water machine and physical and chemical biological experiment ultra-pure water machine?