Study on UV resistance performance of nano composite acrylate adhesive

foreword

Due to the small size of nanoparticles, large specific surface area, high surface free , and easy aggregation between particles, the dispersion of nanomaterials in the finished glue is the difficulty of this research. The dispersion of nanoparticles in the adhesive can be carried out by optimizing the reaction process conditions, surface treatment of nanoparticles or adding auxiliary dispersants, etc., and at the same time it can be completed by high-speed shearing, ball milling and ultrasonic dispersion. [1] .

At present, there are not many studies on the direct dispersion of nanomaterials in the finished glue at home and abroad . The literature that can be used for reference mainly includes Liu Fuchun et al. The nano-titanium dioxide concentrated slurry and the nano-zinc . The role of UV shielding in acrylate coatings Adding a small amount of nano-TiO 2 and nano-ZnO concentrate can significantly improve the UV shielding effect . Liu Yali [3] studied the dispersion performance of nano-TiO 2 and its influence on coating properties. This document mainly studied the pretreatment of nano-TiO 2 through ultrasonic dispersion and the selection of special TiO 2 slurry was prepared by wet grinding method, and then added to automotive coatings. The results show that the particle size distribution of the slurry can be significantly reduced by ultrasonic pretreatment, the light transmittance in the visible light region is above 90%, and the light transmittance in the UV region is less than 5%, with transparency and anti-ultraviolet radiation performance.

In this paper, industrial nanomaterials and acrylic finished glue are used as raw materials, and nanomaterials and finished glue are used in different dispersion processes to study the anti-ultraviolet properties of nanomaterials composite acrylic emulsion. According to the size of the ultraviolet transmittance of the prepared samples , the optimization of the process conditions was carried out.

1 Experimental part

1.1 Experimental materials and reagents

Nano TiO 2 , ZnO, SiO 2 : Shanghai Runhe Nano Material Company; Acrylic Emulsion: Yiwu Changfa Plastic Co., Ltd.; Dispersant: Self-made.

1.2 Experimental instruments and equipment

Ultrasonic cleaner: 5510E, imported from the United States; UV-visible Spectrophotometer : TU- 1810PC, Beijing General Analysis; wire Bar Coater: QXG, Tianjin Shibo Weiye Chemical Glass Instrument Co., Ltd.; initial tack Tester: CZY- G, Jinan Languang Electromechanical Technology Co., Ltd.; holding viscosity Tester : CZY-6S, Jinan Languang Electromechanical Technology Co., Ltd.; peeling Tester : BLD-200S, Jinan Languang Electromechanical Technology Co., Ltd.

1.3 Experimental preparation

(1) Nano pretreatment

Mix and grind the nanomaterials TiO 2 , ZnO, and SiO 2 at a mass ratio of 0.5:0.5:1 , then add a certain amount of self-made dispersant, and ultrasonicate for 10 minutes at room temperature.

(2) Preparation of nanomaterial composite acrylate emulsion

First weigh a certain amount of finished acrylate emulsion glue in a beaker , put it into a Water Bath and start to heat up, when the temperature of the Water Bath rises to 80°C, and stabilize for 30 minutes, start to add the pretreated nano solution dropwise at a rate of 10mL/min. Continue to keep warm for 1 hour after the dropwise addition, then slowly lower the temperature while stirring, stop the reaction when the temperature drops to room temperature, and obtain the acrylate emulsion containing nanomaterials.

(3) Preparation of test samples

Apply the acrylate emulsion containing nanomaterials evenly on the BOPP film with a wire Bar Coater, the film thickness is 20μm, and the coating film thickness is 30~35μm. Baking in an oven at 90°C for 2min is enough.

1.4 Performance test

(1) Ultraviolet-visible light transmittance: TU-1810PC ultraviolet- visible spectrometer is used to accurately test the wavelength of 190~1100nm.

(2) Determination of the solid content of the emulsion [4]: take 2.0000g of the emulsion, accurate to 0.0001g, put it in an oven and dry it at 110°C to constant weight, and calculate the solid content S according to the following formula after weighing

S=m 0 /m 1 ×100%

Where m 0 represents the mass of the emulsion after constant weight, and m 1 represents the mass of the initial emulsion.

(3) Initial tack force[5]: Adopt Labtech CZY-G initial tack Tester , according to GB/T4850-2002 standard, adopt rolling ball slope stop test method to measure (measurement angle is 20°).

(4) Adhesive holding force: adopt Labtech CZY-6S testing instrument, measure according to GB/T4851-1998 standard (the substrate to be adhered is stainless steel, the size of the tape is 25mmx70mm, the roller rolls back and forth 3 times, and the mass of the hanging weight is 1kg), and the holding force is measured by the time when the sample falls off.

(5) 180°peel strength: measured by Languang CZY-6S in accordance with GB/T2792- 1998 standard, using a Tensile Testing Machine (the substrate to be adhered is stainless steel, the tape size is 25mmx125mm, the roller back and forth 3 times, peeling The speed is 300mm/min).

2 Results and discussion

2.1 Effect of nano-dispersion method on emulsion properties

The nano-dispersion method is one of the key factors determining the performance of the emulsion in the preparation process of the nano-material composite acrylate emulsion . Due to the high energy, unsaturation, and instability of the surface of nanoparticles , nanomaterials are easy to agglomerate. To make nanoparticles have a good dispersion , it is necessary to enhance the repulsion between nanoparticles, usually using some physical and chemical methods to disperse nanoparticles [6].

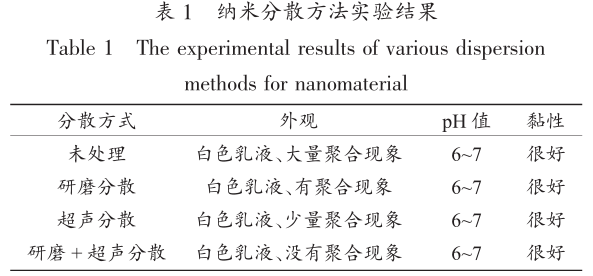

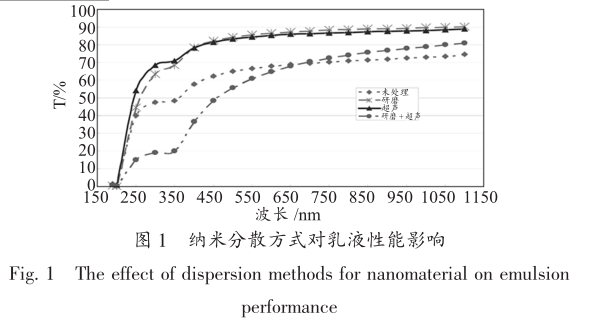

Experimental conditions: rotating speed: 1000rpm, reaction temperature: 80°C, adding amount of nano- solution 2.1%, reaction time 3h, disperse nano-materials in dispersant according to different dispersion methods, the experimental results are shown in Table 1 and Figure 1.

It can be seen from the experimental results in Table 1 that the dispersion method has a great influence on the appearance of the sample. If the nanoparticles are added directly without treatment, a large amount of polymerization will appear . With a single grinding and ultrasonic dispersion, a small amount of polymer also appears in the emulsion. After the combination of grinding and ultrasound, the sample emulsions obtained in the experiment have no polymer generation, and the stability is also good.

由图 1 透过曲线图可知,在波长 190~380nm 的紫外区,紫外透过率由小到大,对应分散方式为研磨 + 超声处理<未处理<研磨处理<超声处理。在波长 190~230nm之间,研磨 + 超声处理样品紫外透过率小于5%。在波长 230~380nm之间,紫外透过率最低的是分散方式为研磨 + 超声处理的样品,其平均透过率为 17.2%;紫外透过率最高的是分散方式为超声处理的样品,其平均透过率为 60.0%。在波长380~760nm 之间可见光区,可见光透过率由小到大,对应分散方式为研磨 + 超声处理<未处理<超声处理<研磨处理。可见光透过率最高的是分散方式为研磨处理的样品,其平均透过率为 85.0%;可见光透过率最低的是分散方式为研磨 + 超声处理的样品,其平均透过率为 59.3%。在波长 760~1100nm之间红外区,所有样品的透过率都在 70%以上。综

合表 1 和图 1 的实验结果,很好的分散方法为研磨 +超声处理的方式。

2.2 纳米溶液添加量对乳液性能的影响

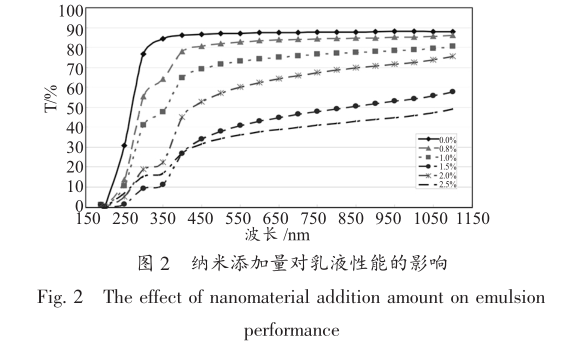

纳米添加量在纳米材料复合丙烯酸酯乳液制备过程中,是决定乳液性能的重要因素之一。实验条件:反应时间:3h、搅拌速度:1000r/min、复配温度:80℃,实验结果如图 2。

由图 2 透过曲线图可知,在波长 190~380nm 之间紫外区,紫外透过率由小到大,对应的纳米添加量为 1.5%<2.5%<2.0%<1.0%<0.8%<0 (成品胶)。在波长 190~245nm之间,除成品胶外其他样品的紫外透过率均小于 5%。在波长 245~315nm之间,紫外透过率最低的是纳米添加量为 1.5%的样品,其平均透过率为 5.8%;紫外透过率最高的是成品胶,其平均透过率为 60.1%;纳米添加量为 1.0%和2.0%的样品,其紫外平均透过率分别为 13.6%和12.3%。在波长 315~380nm之间,紫外透过率最低的是纳米添加量为 1.5%的样品,其平均透过率为11.5%;紫外透过率最高点的是成品胶,其平均透过率为 83.7%;纳米添加量 1.0%和 2.0%的样品,其紫外平均透过率分别为 55.3%和 25.7%。在波长380~760nm 之间可见光区,可见光透过率最低的是纳米添加量为 2.5%的样品,其平均透过率为35.7%;其次是纳米添加量为 1.5%的样品,其平均透过率为 40.1%;纳米添加量为 1.0%和 2.0%的样品,其平均透过率分别为 43.6%和 59.2%。在波长760~1100nm之间红外区,除纳米添加量为 2.5%和1.5%的样品外,所有样品的透过率都在 70%以上。由图 2 实验结果可以看出很好的纳米添加量为 1.5%~2.0%之间。

2.3 反应转速对乳液性能的影响

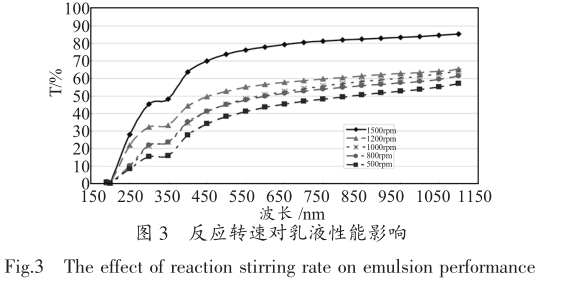

反应转速在纳米材料复合丙烯酸酯乳液制备过程中,是决定乳液性能的重要因素之一。不同反应转速对乳液性能影响如图 3。

由图 3 透过曲线图可知,在波长 190~380nm 的紫外区,紫外透过率由小到大,对应转速为 500rpm<1000rpm<800rpm<1200rpm<1500rpm。在波长190~250nm 之间,500rpm、800rpm、1000rpm 的紫外透过率小于 10%。在波长 250~380nm之间,紫外透过率最低的是转速为 500rpm的样品,其平均透过率为14.8%;其次是转速为 1000rpm 的样品,其平均透过

率为 20.7%;紫外透过率最高的是转速为 1500rpm的样品,其平均透过率为 44.6%。在波长 380~760nm之间可见光区,可见光透过率由小到大,对应转速为500rpm<800rpm<1000rpm<1200rpm<1500rpm。可见光透过率最低的是转速为 500rpm 的样品,其平均透过率为 40.5%;紫外透过率最高的是转速为1500rpm的样品,其平均透过率为75.2%。在波长760~1100nm 之间红外区,所有样品的透过率都在 50%以上。由图 3 可知,很好的反应转速为 800~1200rpm之间。

2.4 反应时间对乳液性能的影响

反应时间在纳米材料复合丙烯酸酯乳液制备过程中,也起着关键的作用,不同反应时间对乳液性能影响如图 4。

由图 4 透过曲线图可知,在波长 190~380nm 的紫外区,紫外透过率由小到大,对应时间为 3h<2h<4h<5h。在波长 190~230nm之间,除反应时间 5h外,其它样品的紫外透过率小于 10%。在波长230~380nm 之间,紫外透过率最低的是反应时间为3h 的样品,其平均透过率为 16.3%;紫外透过率最高的是反应时间为 5h 的样品,其平均透过率为55.9%。在波长 380~760nm之间可见光区,可见光透过率由小到大,对应时间为 2h<3h<4h<5h。可见光透过率最低的是反应时间为 2h 的样品,其平均透过率为 44.4%;其次是反应时间为 3h 的样品,其平均透过率为 59.5%;可见光透过率最高的是反应时间为 5h 的样品,其平均透过率为 76.1%。在波长760~1100nm 之间红外区,除反应时间为 2h 的样品外,所有样品的透过率都在 70%以上。由图 4 的实验结果可以看出很好的反应时间为 3~4h 之间。

2.5 样品涂膜性能测试

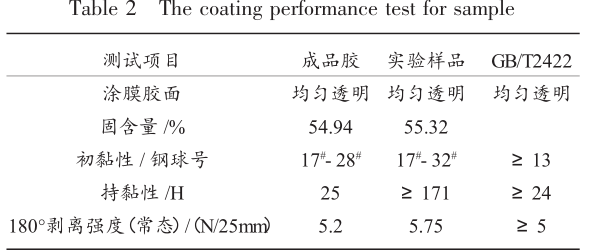

由表 2 实验结果可知,实验样品的涂胶表面均匀透明,实验样品的持黏性很强。样品的初黏性和剥离强度基本达到压敏胶带 GB/T2422- 1998 合格标准 [7] 。

3 结 论

由以上工艺优化实验结果,得到的样品都为白色均匀的黏稠液体,没有聚合物产生,乳液的 pH 值都为中性,乳液的稳定性和黏性都很好。综合紫外和可见光透过率测试结果,很好的工艺条件为:反应温度为 60~80℃、反应时间:3~4h、搅拌速度:800~1200rpm、纳米材料 TiO 2 、ZnO、SiO 2 (质量比0.5∶0.5∶1)、纳米溶液添加量为 1.5%~2.0%、分散剂用量为 7.5~8.5g;纳米分散方法为研磨 + 超声处理的方式;以上样品的涂膜厚度为 0.02~0.07mm。目前实验结果较好的样品为:在波长 190~230nm之间,紫外透过率小于 5%;在波长 230~380nm 之间,其紫外平均透过率为 17%;在波长 380~760nm可 见 光 区 , 其 平 均 透 过 率 为 59% ; 在 波 长760~1100nm红外区,其平均透过率为 70%以上。

参考文献:

[1] 张玉龙,李长德.纳米技术与纳米塑料[M].北京:中国轻工业出版社,2002

[2] 刘福春,韩恩厚,柯伟.抗紫外纳米 TiO 2 / ZnO 复合丙烯酸酯涂料[J].材料研究学报,2003, 17(2):138~144.

[3] 刘娅莉,于占锋,曹银祥,等.纳米 TiO 2 的分散性能及其对涂层性能的影响[J].材料保护,2005,38(11):6~9.

[4] Zhu Yonghua, Wang Shuliang, Yao Jinghua, et al. Anti- ultraviolet light [J]. Functional Materials, 2005,10(36):1607~1613

[5] Wang Yahui, Liu Shimin, Jiang Weiwei, et al. Preparation of Nano-ZnO Powder and Research on UV- Visible Light Absorption Properties[J]. CHINA Ceramic Industry, 2009, 16 (2): 5~7

[6] Liu Guojun, Zhang Guixia, Zeng Hanmin, etc. Effect of Nanoparticle Types on Properties of Polyacrylate Emulsion Pressure Sensitive Adhesive [J]. Chemistry and Adhesion, 2007, 29 (1): 5~7.

[7] Chen Kai. Research on Nano-CaCO 3 Modified Polyacrylate Emulsion Adhesive[D]. Hangzhou : Zhejiang Sci-Tech University, 2010.