How to choose and use a Gas Detector

1. Confirm the type and concentration range of the gas to be detected

Gas Detectors are widely used in petrochemical, environmental protection, gas, coal mine and other industries. For various safety production occasions and detection requirements, it is very important to choose a suitable Gas Detector for every person engaged in safety and health work. 1 Confirm the type and concentration range of the gas to be detected. The types of gas encountered by each production department are different. When choosing a Gas Detector, all possible situations must be considered. For example, in the mining environment of coal mines, methane and less toxic alkanes are mostly, so it is undoubtedly the most appropriate to choose a combustible Gas Detector. This is not only because the detection principle of the combustible Gas Detector is simple and widely used, but also it has the characteristics of convenient maintenance and calibration. If there are toxic gases such as carbon monoxide and hydrogen sulfide, it is necessary to choose a Gas Detector that can detect combustible gas, carbon monoxide, hydrogen sulfide, and oxygen at the same time to ensure the safety of workers. If there are more organic toxic and harmful gases, considering the low concentration that may cause personnel poisoning, such as aromatic hydrocarbons, halogenated hydrocarbons, ammonia (amines), ethers, alcohols, fats, etc., PID photoionization detection should be selected Never use a combustible Gas Detector, as this may result in personal injury or death. If the gas types cover the above types of gases, choosing a composite Gas Detector may achieve twice the result with half the effort

2. Determine the use occasion

Different industrial environments require different types of Gas Detectors.

(1) Fixed Gas Detector

This is a Detector that is widely used in industrial devices and production processes. It can be installed on a specific detection point to detect specific gas leaks. The fixed Detector is generally divided into two types. The detection probe composed of sensors and transmission elements is installed on the detection site, and the secondary instrument composed of circuits, power supplies and display alarm devices is installed in a safe place for easy monitoring. The fixed Gas Detector is more suitable for the characteristics of continuous and long-term stability required by the detection in terms of process and technology. It also needs to be selected according to the type and concentration of the on-site gas, and at the same time, it is necessary to pay attention to installing them in the part where the specific gas is most likely to leak, such as selecting the effective height of the sensor installation according to the specific gravity of the gas.

(2) Portable Gas Detector

Because the portable instrument is easy to operate and small in size, it can be carried to different production sites. The Detector of the electrochemical sensor is powered by alkaline batteries and can be used continuously for 1000 hours; the new combustible Gas Detector, PID photoionization Detector and Composite Detectors use rechargeable batteries (some have used memoryless nickel metal hydride or lithium ion batteries, so that they can generally work continuously for nearly 12 hours, so the application of such instruments in various factories and health departments is becoming more and more popular. wide.

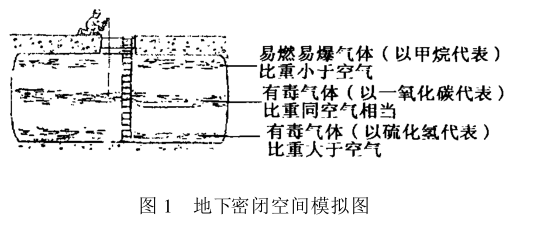

If this type of instrument is used as an alarm in an open place, such as an open workshop, a wearable diffusion gas Detector can be used, because it can continuously, real-time, and accurately display the concentration of toxic and harmful gases on site. These newer instruments also come with a vibrating alarm accessory—to avoid inaudible alarms in noisy environments—and a computer chip to record peak, STEL (15-minute short-term exposure levels) and TWA (8-hour statistically weighted average). value)—provides specific guidance for worker health and safety. If you enter a confined space, such as a reaction tank, storage tank or container, sewer or other underground pipelines, underground facilities, agricultural closed granary, railway tanker, shipping cargo hold, tunnel and other workplaces, you must choose a built-in sampling pump. Multi-Gas Detector. Because the gas distribution and gas types in different parts of the confined space are very different. For example: the specific gravity of flammable and explosive gases in the general sense is relatively light, and most of them are distributed in the upper part of the confined space; the specific gravity of carbon monoxide and air is similar, and it is generally distributed in the middle of the confined space; It exists in the lower part of the confined space, as shown in Figure 1.

At the same time, oxygen concentration is also one of the types that need to be detected. In addition, if volatilization and leakage of organic toxic gases are considered, a Detector that can detect organic gases is also needed. Therefore, a complete Gas Detector in a confined space should be equipped with a built-in pumping function --- so that non-contact, sub-site detection; multi-Gas Detector --- to detect dangerous gases distributed in different spaces, including inorganic gases and organic gases Gas; Oxygen Detector——Prevent hypoxia or enrichment of oxygen. Only in this way can the absolute safety of the staff entering the confined space be guaranteed. In addition, after entering the confined space, the gas composition in it must be continuously detected to avoid changes in the concentration of volatile organic compounds or other toxic and harmful gases due to personnel entry, sudden leakage, and temperature changes.

If it is used for emergency accidents, leak detection and patrolling, pump-suction instruments with short response time, high sensitivity and resolution should be used, so that the location of the leak point can be easily judged. In the case of industrial hygiene inspection and health investigation, it is very convenient to use instruments with functions such as data recording, statistical calculation and connection with computers.

At present, with the development of manufacturing technology, portable multi-gas (composite) Detector is also a new choice for us. Because this Detector can be equipped with multiple gas (inorganic and organic) detection sensors required on one host, it has the characteristics of small size, light weight, and multi-gas concentration display at the same time. More importantly, the price of the pump-suction composite Gas Detector is cheaper than that of multiple single-diffusion Gas Detectors, and it is more convenient to use. It should be noted that when choosing this type of Detector, it is better to choose an instrument with the function of switching each sensor separately, so as to prevent the damage of one sensor from affecting the use of other sensors. At the same time, in order to avoid blockage due to water inflow, it is safer to choose an instrument designed .

Misunderstandings in choosing toxic and harmful Gas Detectors:

In our country, due to historical and cognitive reasons, there are still many problems in the selection of various Detectors, which are specifically reflected in:

a. The detection of flammable gases is more important than the detection of toxic gases.

b. The detection of gases that may cause acute poisoning is more important than the detection of gases that may cause chronic poisoning.

Due to the bloody lessons of explosion accidents caused by the leakage of many combustible gases, people attach great importance to the detection of combustible gases. It can be said that any oil refinery, chemical plant, and most of the Gas Detectors used in dangerous places are combustible Gas Detectors. Detector. However, it is far from enough to only equip combustible Gas Detectors to truly protect the safety and health of workers. It is undeniable that most of the volatile dangerous gases are flammable and explosive gases, but the catalytic combustion flammable Gas Detector (LEL) is not a good choice for the detection of all flammable gases . Because the lower limit concentrations of combustible gases other than methane that they can detect are much higher than their allowable concentrations. For example: For dangerous and toxic gases such as benzene and ammonia, it is a very dangerous practice to simply use flammable and explosive Gas Detectors. For example, the lower explosion limit of benzene is 1.2%, and its correction coefficient on the combustible Gas Detector is 2.51, that is to say, the concentration of benzene displayed on a combustible Gas Detector calibrated with methane is only 40% of its actual concentration !!In this way, the lowest alarm concentration of benzene that can be detected by a combustible Gas Detector is 10%LEL=10%*1.2%*2.51=3.0*10-3, which is the same as the allowable concentration of benzene 5*10-6 Nearly 600 times higher than that!!. Similarly, the alarm concentration of 1.5*10-2 detected by the combustible Gas Detector is about 1000 times higher than the allowable concentration of 5*10-5. Therefore, according to the different gases to be detected, it is safer and more reliable to choose a specific toxic Gas Detector than to simply choose a combustible Gas Detector.

In addition, at present, we pay more attention to the detection of gases that can cause acute poisoning, such as hydrogen sulfide and hydrogen cyanide, but not enough attention to the detection of gases that can cause chronic poisoning, such as aromatic hydrocarbons and alcohols. The hazards to the health and safety of workers are no less than the gas that can cause acute poisoning! In addition to the reasons for cognition, the lack of Gas Detectors that can detect lower concentrations in the previous market is also an important reason.

With the development of science and technology and the improvement of people's health awareness, people are no longer satisfied with "going to work happily and going home safely", but are pursuing higher quality of life and living conditions. People are not only concerned about today's work, but also about tomorrow --- life after retirement. Therefore, in the work of industrial hygiene and industrial safety, we must constantly introduce new concepts and new ideas in order to avoid future tragedies. And to avoid future tragedies, all of these need to be continuously improved and improved through the formulation of regulations and the improvement of people's quality.

The problems that need to be paid attention to when using Gas Detectors are:

① Pay attention to regular calibration and testing

The toxic and harmful Gas Detector is the same as other analysis and detection instruments, and it is measured by the method of relative comparison: firstly, the instrument is calibrated with a zero gas and a gas with a standard concentration, and the standard curve is obtained and stored in the instrument. During the measurement, the instrument compares the electrical signal generated by the gas concentration to be measured with the electrical signal of the standard concentration, and calculates an accurate gas concentration value. Therefore, zero calibration of the instrument at any time and frequent calibration of the instrument are all required work to ensure accurate measurement of the instrument. It should be noted that many Gas Detectors can replace the detection sensor at present, but this does not mean that a Detector can be equipped with different Detector probes at any time. Whenever the probe is replaced, in addition to a certain sensor activation time, the instrument needs to be recalibrated. In addition, it is recommended to test the response of the standard gas used for the instrument before using it, so as to ensure the accuracy and effectiveness of the instrument.

② Pay attention to the detection interference between various sensors

Generally speaking, each sensor corresponds to a specific detection gas, but any sensor is not absolutely specific. Therefore, when choosing a gas sensor, we should try our best to understand the interference of other gases to the sensor, so as to ensure its accurate detection of specific gases.

③ Pay attention to the life of various sensors

All kinds of gas sensors have a certain service life, that is, life. Generally speaking, among portable instruments, combustible gas sensors have a longer service life, which can generally be used for about three years; photoionization Detectors have a service life of four years or longer; electrochemical specific gas sensors have a relatively short service life, Generally one to two years; the life of the oxygen sensor is the shortest, about one year (the life of the electrochemical sensor depends on the dryness of the electrolyte in it, so if it is not used for a long time, it should be sealed in a lower temperature environment can prolong the service life). Due to the relatively large size of the fixed instrument, the life of the sensor is also longer. Therefore, it should be used within the validity period of the sensor as much as possible, and once it fails, it should be replaced in time.

④ Pay attention to the concentration measurement range of the detection instrument

All kinds of toxic and harmful Gas Detectors have their fixed detection range. Only when the measurement is completed within its measurement range can the instrument be accurately determined. However, measuring beyond the measurement range for a long time may cause permanent damage to the sensor. For example, if a combustible gas detection instrument is accidentally used in an environment exceeding 100% LEL, it may effectively burn the sensor. For toxic Gas Detectors, working at a higher concentration for a long time will also cause damage. Therefore, if the fixed instrument sends an over-limit signal during use, the measurement circuit should be closed immediately to ensure the safety of the sensor.

In short, toxic and harmful Gas Detector is a powerful tool to ensure industrial safety and staff health. We need to choose the appropriate Gas Detector according to the specific use environment and required functions. At present, the Detectors available to us include fixed portable, diffusion pump suction, single gas multi-gas, inorganic gas organic gas and other combinations. Only by choosing a suitable gas detection instrument can we truly achieve twice the result with half the effort and prevent problems before they happen.

- 1Principle and Application Analysis of Composite Four-in-One Gas Detector

- 2Introduction to Working Principle and Application of Carbon Monoxide Gas Detector

- 3Basic Principle and Application of Portable Gas Detector

- 4Basic Principle and Application Analysis of Gas Detector

- 5What is the alarm value of Gas Detector?

- 6What is phosphating Gas Detector?

- 7What is a combustion analyzer?

- 8Application Scheme of Gas Detector in Coking Coal Metallurgy Industry

保时安 - 《保时安》

- 9Application of Gas Detector in Medical Manufacturing

保时安 - 《保时安》