PosiTector UTG Ultrasonic Film thickness probe - Operating principle

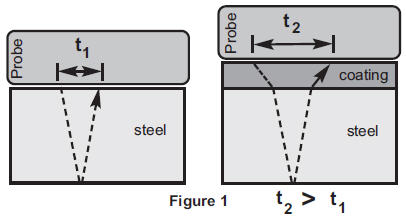

PosiTector UTG probes transmit ultrasonic pulses into the material under test. This pulse travels through the material towards the other side. When encountering an interface such as air (back wall) or other material, the pulse is reflected back to the probe. The time it takes for the pulse to propagate through the material is measured by the gage and is denoted as t1 and t2 below.

PosiTector UTG C and PosiTector UTG M (single echo  mode) transducers determine thickness by measuring t1 (uncoated) or t2 (coated), dividing it by 2, and multiplying by the sound velocity of the material (steel). see picture 1.

mode) transducers determine thickness by measuring t1 (uncoated) or t2 (coated), dividing it by 2, and multiplying by the sound velocity of the material (steel). see picture 1.

For uncoated materials, t1 is directly related to the material thickness. When the material is applied, the propagation time increases and is shown above as t2.

Coatings such as paint have a slower speed of sound than metals. Therefore, the single-echo technique will produce thickness results that are greater than the actual combined coating + metal thickness.

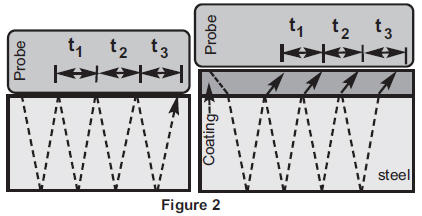

The PosiTector UTG M in multi-echo mode

determines thickness by measuring the time between at least three consecutive back wall echoes.

determines thickness by measuring the time between at least three consecutive back wall echoes.

In the image above, the multi-echo mode only measures the time between echoes. All times between echoes are the same whether the steel is coated or not. In multi-echo mode, the Gage determines thickness by measuring t1 + t2 + t3, dividing it by 6, and multiplying by the sound velocity of that material. Therefore, the final thickness calculation performed by the instrument is only an accurate measurement of the steel thickness and does not take into account the coating thickness.

The speed of sound is expressed in inches/microsecond or meters/second. All materials are different. For example, sound travels through steel (~0.233 in/μs) faster than through plastic (~0.086 in/μs).

- 1Measure gloss with a PosiTector GLS gloss meter

Defelsko

- 2Erosion and Corrosion Coating Thickness Testing of Defelsko Coating Thickness Gauge Solutions

- 3PosiTector 200 ® Operation Manual V 3.1

- 4PosiTector UTG Ultrasonic Wall Thickness Meter calibrated and Accuracy verified

- 5PosiTector Software Update Instructions

- 6Which probes is the PosiTector host suitable for? A table tells you

- 7PosiTector 6000 Coating Thickness Gauge FAQ

- 8Defelsko Instruments integrates with third-party devices and applications

- 9PosiTector SPG Roughness Profile Gauge FAQ

Defelsko - 《Defelsko》

-

-

-

Defelsko FTRS Thickness Gauge Probe$ 904.00

-

-

-