Surface profile measurement options for rough/pitted steel surfaces

introduce

Surface profile is defined as the measurement of the maximum peak-to-valley depth produced by blast cleaning and impact power tools. These operations effectively increase the surface area and provide an "anchor" for the applied coating system. The depth of the surface profile needs to be commensurate with the total thickness of the coating system; generally, the thicker the coating system, the deeper the surface profile. For example, a 3 coat 15 mil system may require a 2-3 mil surface profile, while a 40 mil coat system may require a 4-5 mil surface profile. With G10 or G12 abrasives, the maximum achievable surface profile is typically 6-7 mils (in steel).

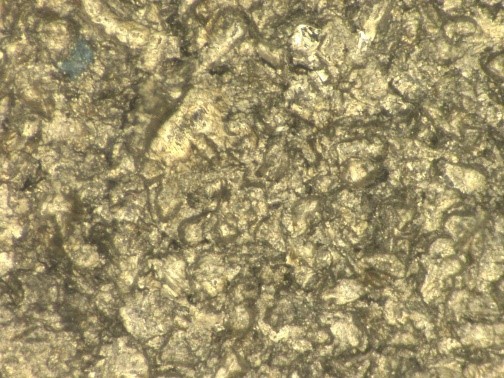

Frequent inspection of blast cleaned and power tool cleaned steel surfaces to verify that the specified surface profile has been achieved. Industry standards such as ASTM D4417, Standard Test Method for In-situ Measurement of Surface Profile of Blast Furnace Cleaned Steel [1], NACE International SP0287, Standard Practice for In-situ Measurement of Surface Profile of Abrasively Cleaned Steel Surface Using Replica Tape, and SSPC: Association for Protective Coatings PA 17. Procedures for Determining Compliance with Steel Profile/Surface Roughness/Peak Counting Requirements describes the procedure for performing these measurements, along with the recommended frequency of measurements and acceptability of values. However, the standard assumes that smooth steel is prepared; there are few articles on measuring surface profiles on rough or irregular surfaces, such as pitted steel [2], weathering steel or cast iron surfaces. This short article describes some of the methods that can be used to measure surface profiles on these types of irregular surfaces.

background

Many steel structures that have been in use for a long time may have irregular rough surfaces due to corrosion. This often results in a loss of thickness of the steel (loss of section), which may even require modification or replacement. But when it was determined that sufficient metal loss had not occurred to warrant repair of the steel substrate, the applicator was faced with meeting the contractual cleanliness and profile resulting in a surface roughness that often exceeded the contractual surface profile.  Likewise, other steel surfaces such as cast iron and weathering steel (ASTM A588, A242, A606-4, A847, and A709-50W), after weathering from atmospheric conditions, generally have rougher surfaces than blast-cleaned ASTM A36 steel, and may Resulting in higher surface profile yields and subsequent rejections than the specification allows.

Likewise, other steel surfaces such as cast iron and weathering steel (ASTM A588, A242, A606-4, A847, and A709-50W), after weathering from atmospheric conditions, generally have rougher surfaces than blast-cleaned ASTM A36 steel, and may Resulting in higher surface profile yields and subsequent rejections than the specification allows.

在粗糙或凹坑表面上测量表面轮廓通常会导致错误的高读数,因为测量结果表明了凹坑的深度或钢的固有粗糙度与磨料或冲击型动力工具本身产生的表面轮廓。这引出了一个问题,“你如何以任何精确度验证这些类型表面上的表面轮廓?”可以考虑一些替代方案; 但是,应该讨论它们,并且在可能的情况下,在预建会议期间而不是在过程测量期间协商一种方法。

替代方法 第一种选择是使用选择/指定的任何方法(深度千分尺或复制带)在相邻区域(非粗糙)中获得测量值。然而,当点蚀或粗钢均匀时,这可能是不可行的。在参考标准中列出的三种方法中,深度千分尺(ASTM D4417中的方法B)在这些情况下通常被认为是很好的的,因为可以获得单个谷的测量值,并且仪器的上限范围更高(20密耳) )使用复制带(5密耳)可以合理测量的最大值。在一个区域内进行多次测量(至少十次),并计算平均表面轮廓[3]。

第一种选择是使用选择/指定的任何方法(深度千分尺或复制带)在相邻区域(非粗糙)中获得测量值。然而,当点蚀或粗钢均匀时,这可能是不可行的。在参考标准中列出的三种方法中,深度千分尺(ASTM D4417中的方法B)在这些情况下通常被认为是很好的的,因为可以获得单个谷的测量值,并且仪器的上限范围更高(20密耳) )使用复制带(5密耳)可以合理测量的最大值。在一个区域内进行多次测量(至少十次),并计算平均表面轮廓[3]。

另一种选择是依靠视觉比较器和参考光盘。比较器是一个发光放大镜(通常为5-10倍功率),使用户能够仔细检查表面粗糙度,并将其与包含不同粗糙度的复制光盘(每个光盘5个段)进行比较。将代表所用磨料(砂砾/熔渣或喷丸)的合适参考盘置于所制备的钢上,并且使用者选择较接近钢的表面轮廓的段。

另一种选择是依靠视觉比较器和参考光盘。比较器是一个发光放大镜(通常为5-10倍功率),使用户能够仔细检查表面粗糙度,并将其与包含不同粗糙度的复制光盘(每个光盘5个段)进行比较。将代表所用磨料(砂砾/熔渣或喷丸)的合适参考盘置于所制备的钢上,并且使用者选择较接近钢的表面轮廓的段。

第三种选择是测量配对钢板上的表面轮廓,例如用粗磨钢上使用的相同磨料和压力进行喷砂清理的测试板。在绘制铸铁电动机外壳时,该程序已被核电工业多年接受。

最后,可以参考磨料制造商关于由所使用的类型和尺寸磨料产生的典型表面轮廓值。一些磨料制造商可以提供一致性证书,其说明在实验室条件下给定批次的测量范围。请注意,表面硬度会极大地影响表面轮廓深度,因此磨料制造商的数据可能会产生误导。

结论

需要记住的重要一点是,当表面粗糙或不规则时,可以使用这些方法中的一种或多种来更准确地确定表面轮廓深度。此外,粗糙表面可能需要施加较厚的涂层或额外的涂层以帮助确保防腐蚀。涂料制造商在做出这些决定时应该参与其中。

[1] According to SSPC-SP 11 and SP 15, verification of a minimum 1 mil surface profile produced by a power tool can only be measured using Method B (depth micrometer) as described in the ASTM D4417 standard.

[2] SSPC-PA 17-2012 addresses the measurement of the surface profile of denucleated steel in Appendix C (Section C2.5.3)

[3] ASTM D4417 instructs operators to report a maximum of ten measurements; however, use on rough/dimpled surfaces is not recommended. This standard allows for average readings.

- 1Surface profile measurement

- 2How to measure concrete surface profile (roughness) quantitatively

Defelsko

- 3What is a Surface Profiler?

- 4Differences in Surface Profile Measurements: ASTM D4417 - Method B vs Method C

- 5Comparison of surface profile measurement methods

-

Defelsko positector SPG1 Roughometer$ 890.00