Introduction of a pull-off test instrument according to ASTM C1583

BOND-TEST uses a pull-off test according to ASTM C1583, "Test Method Tensile Strength and Bond Strength of Concrete Surfaces or Tensile Strength of Concrete Repair and Overlay Material by Direct Tension (Pull-Off Method)" The pull-off strength obtained is available for the following purposes:

Evaluate the in-situ bond strength between the repair overlay and substrate

Evaluate the in situ tensile strength of concrete or other materials

Evaluate the effect of surface preparation procedures on the tensile strength of substrates prior to application of repair materials or overlays

principle

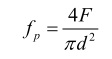

In the BOND-TEST, the disc is glued to the prepared test surface and the disc is pulled after cutting a portion of the core around the disc (far left in the image below). The pull-out force F is divided by the cross-sectional area of the partial core to obtain the pull-off strength fp:

where d is the diameter of the partial core. BOND-TEST

The types of failures that can occur in are described above: (a) failure of the substrate indicates that the bond strength is greater than the tensile strength of the substrate; (b) failure at the interface provides a measure of the tensile bond strength between the cover layer and the substrate ; (c) Failure of the overlay indicates that the bond strength is greater than the tensile strength of the overlay. It is very important to introduce negligible flex into the disc by the loading system during testing. Otherwise, low and unstable test results will be obtained.

Failure type (a) is preferred because it indicates that the bond strength of the cover is greater than the tensile strength of the substrate. Note that failure occurs at the weakest link of a composite system, and it is impossible to predict what type of failure will occur. When calculating the average pull-off strength, only the results of tests with the same type of failure should be averaged.

The properties of BOND-TEST have been investigated by finite element analysis (see Petersen, CG, Dahlblom, O. and Worters, P., "Adhesion tests of concrete and overlays", Proceedings, International Conference on NDT in Civil Engineering, UK University of Liverpool, 1997; Bungey, JH and Madandoust, R., Factors Affecting Concrete Pull-Off Tests, "Mag. of Concr. Res., 1992, 44, No. 158)). Anticipated BOND-TEST using 75mm discs Failure occurred at a displacement of 0.02mm to 0.03mm, and the nominal stress in the partial core prior to rupture was approximately 3% lower than the uniaxial tensile strength of the base concrete.

variability

For 75mm discs, the coefficient of variation in the results of repeated tests was approximately 8-10% for concrete with a maximum aggregate size of 38mm. For a 50mm disc, the coefficient of variation is 14 to 16%.

The BOND-TEST program

1. Surface planing

The surface is ground with a diamond set planer tool to expose the aggregate and obtain a flat surface. Use a separate wheel Grinder to remove the remaining center knob. The dry surface is steel brushed so any dust or powder is blown away. Suction cups are used to stabilize the planer. Note that cooling water is not used for this operation.

2. Bonding the Disc

The clean disc is bonded to the prepared surface using a fast curing adhesive (GRA). The GRA adhesive has a tensile strength of 10MPa when fully cured and takes 2 to 5 minutes at normal temperature. Progression of sclerosis was observed in small cups mixed with two-component GRA. In cold weather conditions, the concrete surface and disc are heated with a heat gun to speed up the curing of the adhesive.

3. Partial

coring uses cooling water to cut partial cores perpendicular to the surface; the bonded disc is used as a drilling guide (the inner diameter of the core bit is slightly larger than the disc diameter). Part of the core is cut with CORECASE. For tests to measure bond strength, the core is cut into the substrate to a depth of 25 mm or half the diameter of the core, whichever is greater; for tensile strength of the substrate, the cut depth is 25 mm.

4. Pull out

The disk is directly loaded at a controlled rate using a calibrated hydraulic puller. The machine is the same as the one used for the pull-out test, resting on a circular counter-pressure ring located in the center of the planed surface. The peak force in kN was recorded and used to obtain the pull-off strength by dividing by the cross-sectional area of the partial core. Record the type of failure, (a), (b) or (c), as indicated on the previous page.

The procedures and special equipment used for BOND-TEST ensure that the discs are loaded in direct tension without bending. Bending can reduce results by 20% to 50%. The disk has sufficient stiffness to avoid deformation during the test. By bonding a clean disc to a planed dry surface with GRA adhesive, failure should not occur at the disc/overlay interface. Failure at the disc/cover layer interface is an indeterminate test that needs to be repeated if the bond strength is to be assessed.

test case

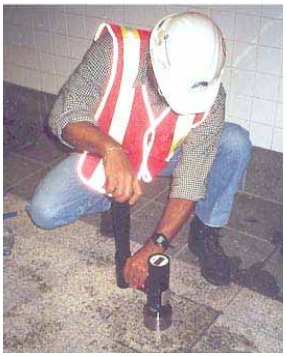

BOND-TEST for quality control of the bond between wear-resistant overlay and concrete slab; showing sampling (left), application of tensile load (middle), and bond failure, type ( b), between the cover layer and the substrate (right), 1.8 MPa

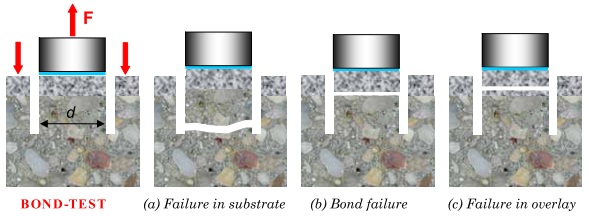

BOND-TEST is at the subway station

Repairs made on granite tiles Repairs on balconies evaluated with BOND-TEST

- 1How to measure concrete surface profile (roughness) quantitatively

Defelsko

- 2Research and analysis of influencing factors of concrete wear resistance

- 3How to measure moisture in concrete (positector CMM IS Moisture Meter)

- 4Concrete and plastering surface brush emulsion paint work instructions

- 5Analysis of FAQ and Countermeasures in Testing of Anti-corrosion Coatings for Concrete

李欣; 赵苑; 杨表芳 - 《混凝土用防腐涂料检测中常见问题的探讨》