Onset U23-001 temperature transducer for energy efficiency research on white roofs and non-white roofs

After 18 years of extreme desert heat, the Nationwide® Scottsdale Insurance Company headquarters building in Scottsdale, Arizona began the natural process of deterioration. Maintenance crews had been chasing the leak for nearly five years when they hired Allen Stevens Associates Inc. to fix the problem and bring their roof system into the 21st century.

The original roof system was a ballasted EPDM/4" R-20 roof with insulation on the concrete roof deck, and a 2" rock cover. Compared to modern heat resistant roofing systems that are used in Arizona today, this is quickly becoming a major liability with regard to structural integrity, maintenance costs and energy consumption.

The new Cool Roof System by Stark Weizer's Character Gradient Roofing was installed in December 2008 by 3" R-19 ISO with tight-set roof panel insulation adhesive bonded to the concrete roof panel, and a self-adhesive styrene plastic Eastoflex Dried Dachshund Base Map and PolyKool Cap Sheet. This roof system is able to withstand Arizona's notoriously extreme temperatures and rapid temperature changes during the summer monsoon season.

PolyKool sheets are white reflective surfaces (solar reflectance index value 84) that not only meet all current and proposed energy efficiency standards, but also withstand constant foot traffic, standing water from the building's cooling tower and residual chemicals.

For more information on this massive project, please read this article published in the July/August 2009 edition of Western Roofing magazine.

Are white roofs more energy efficient than non-white ones?

On the Arizona Cool Roofs Commission in July 2009, Starkweather's character Gradual Roofing set out to determine that white roofs are indeed cooler, more energy-efficient roofs than non-white roofs. Nationwide® Scottsdale Insurance Company This in-depth Cool Roof Roof is a good option to research.

On the morning of August 6, 2009, Starkweather's character Gradually Chris Walker and Sherm Robinson Roof installed Onset's HOBO series data loggers directly on the roof's upper surface in a low-flow, vacuum-conditioned stairwell Nationwide® Scottsdale Insurance Company building next door and building in the same Enterprise Square (still with the original EPDM roof system): this is a good "before and after" condition, yes, the results will be based on the same climate conditions with data from a year to Next in the same building, many different variables can affect the outcome.

The temperature sensor U23-001 on the roof obtains accurate readings under the surface of the material used in the current roof system, which does not allow direct sunlight to affect the reading and gives an accurate surface temperature in each building. Temperature sensors U23-001 placed in the vacuum condition stairwell are measured directly from the roof hatch and secure the three feet of the concrete roof slab to the roof's energy saving system (in other words, they measure how much heat is being transferred through the concrete deck into the interior of the building).

Sensors measure roof surface and stairwell temperatures in both buildings hourly, 24 hours a day from August 6 to September 4. Official temperature data for Scottsdale was obtained at the same time interval and at the same time. During the data collection period Scottsdale had predominantly hot and sunny days, with a few monsoon rain showers, allowing near-good testing conditions.

Conditions in this study were considered near good for a number of reasons. First, it's side by side identical buildings. Second, an old roof system and other new cool roof system - soa before and after analysis may be done at the same time, under the same conditions. Finally, a concrete deck is not typical in Arizona (plywood decks are more common). If the data prove any significant increase in energy efficiency in building construction, it is known that greater results are obtained with t buildings typical of Arizona roof structures.

Our Analysis and Conclusions

Conclusion 1: White roof reduces thermal shock

|

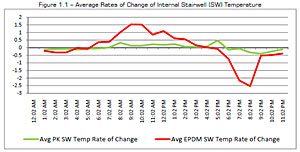

| Figure 1.1 - Internal staircase (SW) temperature for mean exchange rate change |

The first thing that caught our attention was the dramatic reduction in thermal shock, which is a direct result of a more consistent cool roof surface and internal building PolyKool roof temperatures.

Thermal shock is minimized by slowing down the rate of temperature change (up and down) on the roof surface, which in turn virtually eliminates the rate of temperature change inside the building. The way to reduce thermal shock is to use materials with greater strength, increased thermal conductivity and lower coefficient of thermal expansion, but this method is more expensive and does not guarantee good results.

The rate of temperature change inside an EPDM building is expected to be that it heats up faster, and cools down faster. But even more surprising is how the temperature inside the PolyKool building is regulated. The temperature change in the EPDM stairwell is 3.75 times that of the PolyKool stairwell. In fact, there are so few temperature variations on PolyKool stairs that we are now led to assume that internal thermal shock may be eliminated entirely, whereas maintaining a constant internal temperature is much easier:

Note that the internal temperature between 6pm and the building is very similar, but the EPDM building is always warmer than the PolyKool building. At 8:00 am the EPDM building starts to heat up dramatically while the PolyKool building remains almost unchanged. After, between 5:00 pm and 8:00 pm, the EPDM building cools down even faster than it heats up again, the PolyKool building maintains a constant internal temperature.

|

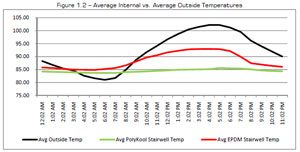

| Figure 1.2 - Average internal and external average temperatures |

Figure 1.2 shows the internal temperature change due to the external temperature. Note that the PolyKool building remains almost constant throughout the day while the EPDM building fluctuates rapidly. The average internal temperature is only 1.94 degrees from the hottest and coolest days inside the PolyKool building. Conversely, EPDM construction typically has an internal temperature in the 7.67-degree range over a 24-hour period. In a building these two are as large, nearly 8 degrees means a lot of extra energy is needed for building tenants to maintain a consistent temperature.

Conclusion 2: White roofs improve energy efficiency

On a typical hot August day in Scottsdale, Arizona, a white roof was 4.62% cooler (energy efficient) than a non-white roof. On the hottest day in the building (5:00 pm), white roofs were 8.49% cooler (energy efficient) than non-white roofs. The maximum internal temperature of the parking lot increases by hour - 5:00 pm, and the white roof is 6.97% cooler than the non-white roof (energy saving).

Based on these data, we would suspect that an 8kW PolyKool roofed building should consume about 7.00% less year-over-year or more (when it has a roof ballasted EPDM), assuming all other items remain equal.

In August 2008, the Nationwide® Scottsdale Insurance Company headquarters building in Scottsdale, Arizona consumed 719,000 kW of electricity. According to maintenance supervisor Chris Peterson, all other projects from 2008 remained virtually unchanged, while the installation of the PolyKool roof system was a substantial difference in 2009. In August 2009, consumption was 663,000 kW - a 7.79% (or $5,450) reduction in the electricity needed to cool buildings (more energy efficient).

This is concrete on a building roof deck. Also note that the PolyKool cap table only has a Solar Reflectance Index (SRI) value of 84. If the building has a plywood roof deck (which is more typical in Arizona) and if the material used has a high Sri value (100 is typical for a good roof coating), the energy savings will be even greater. Gradually Roof Starkweather has begun to perform a similar analysis using plywood for building roof decks as well as comparing results with higher Sri Lankan value roof coatings.

Conclusion #3: White roofs reduce roof surface temperatures

|

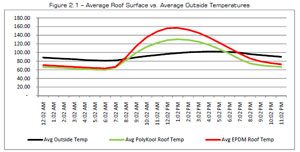

| Figure 2.1 - Average roof exterior surface vs. average temperature |

|

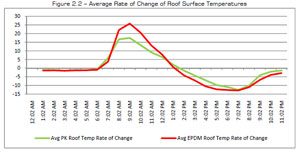

| Figure 2.2 - Average rate of change of roof surface temperature |

PolyKool cool roofs are on average 12 degrees (13.57%) cooler than EPDM roofs. But overnight, including when there is no direct sunlight.

Figure 2.1 shows that the older roof surface temperature was the larger variance in our study, when the outdoor temperature averaged 96.66°F. EPDM roofs average 156.28°F, but PolyKool roofs only have 128.59°F. A difference of 27.69 degrees (the EPDM roof is 26.69% hotter). From 9:00 am to 5:00 pm (maximum sunlight hours), there was an average of 22.40 degrees (18.55%) difference in roof surface temperature—very important for the long-term survival of roof equipment (and building facility workers).

As shown in Figure 2.2 below, the roof surface temperature increased between 6:00 and 8:00 am for the building similarly, but the EPDM roof was getting hotter, while the PolyKool building started to level off. Also, a PolyKool building cools more gradually than an EPDM building, heats up very quickly, gets extremely hot, and then cools down faster (although it never gets cooler than a PolyKool roof). Back to the same temperature change until 7pm. This is another sign of the reduced thermal shock of PolyKool roof cooling.