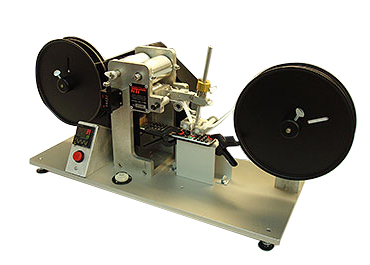

RCA tape Wear testing machine for industrial anticorrosive paint testing

The development of water-based industrial anti-corrosion baking paint is a key breakthrough, because the volatility of water is much smaller than that of organic solvents, and the water resistance, anti-penetration and anti-corrosion capabilities of water-based coatings are much lower than oil-based anti-corrosion coatings, so how to choose a good amino-cured water-based resin and the best formula Adaptation must test the patience and ability of the paint designer. Generally, it takes time to verify the anticorrosion ability by salt spray, but the RCA paper tape friction test can know the performance of the coating film in a short time.

Performance Testing

Fineness: QXD Fineness Meter, measured according to GB/T 1724--1979 (1989) paint fineness test method;

Solid content: Drying oven DHG-9146A, AC204 precision balance, according to GB/T 1725--1979 (1989) Determination of solid content of paint;

Hardness: BY-type pencil Hardness Tester (domestic), measured according to GB/T 6739-2006 pencil method;

Adhesion: BYK cross-cut device (USA), measured according to the cross-cut test of GB/T 9286-1998 paint film;

RCA friction test: paper tape Tester (USA) RCA paper tape, measured according to the requirements of ASUS (ASUS test standard);

American Normantool 7-IBB-CC Paper Tape Abrasion Tester

Impact resistance: DuPont impact meter YH-9218 (USA), measured according to GB/T 20624.1--2006, GB/T 20624.2_-2006 impact resistance test method for large and small punches;

Bending: cylindrical bending Tester TWZ-8 (domestic), measured according to GB/T 6742--1986 paint film bending test (cylindrical shaft);

Wear resistance: Mingchi wear Tester MC-803 (Taiwan, CHINA), measured according to ASUS requirements;

Alcohol resistance: Mingchi wear Tester MC-803 (Taiwan, CHINA), measured according to ASUS requirements;

Salt spray resistance: salt spray Tester ST-BC-N (domestic), according to GB/T 177l-199l neutral salt spray test method;

Film thickness: QUANIXl500 film thickness Tester (Germany), measured according to GB/T 13452.2.-92 paint film thickness test method.

Purpose

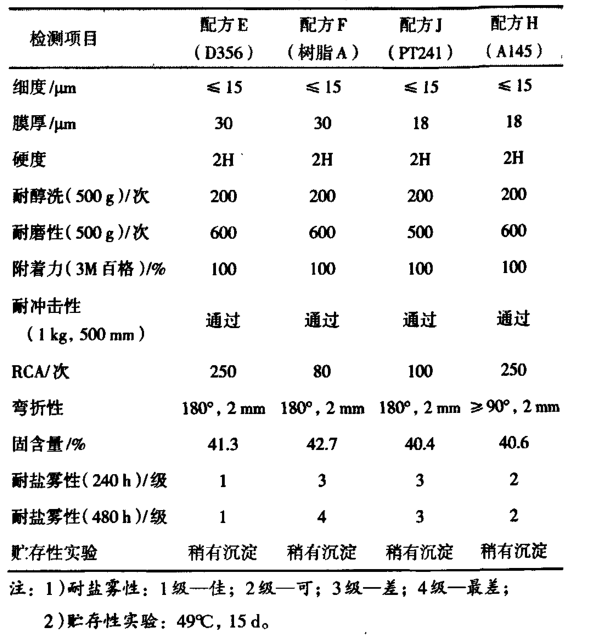

The purpose of the experiment is to find out the anti-corrosion primer resin suitable for industrial use, which is used for indoor and outdoor components, indoor and outdoor electrical shells or indoor and outdoor sports equipment, indoor and outdoor iron furniture, so in addition to hardness, salt spray resistance, In addition to conventional performance tests such as adhesion, bending, and impact resistance, RCA paper tape abrasion resistance, alcohol abrasion resistance, rubber abrasion resistance, and storage stability tests required by the 3C industry have also been added.

There is an absolutely inverse relationship between crosslink density and water penetration. The protective ability of the coating depends on the penetration ability of its corrosion-resistant medium, so AC impedance technology, such as EIS, is widely used in the field of corrosion science. Generally, industrial paint and coating factories do not have such equipment, but most of them have RCA tape Testers and salt spray machines. Therefore, this experiment compares the RCA measured value with the salt spray resistance performance.

- 1Introduction to common wear resistance test methods

- 2Principle, Application and Selection of Adhesive Tape Wear testing machine

- 3Briefly introduce the working principle, application and selection precautions of rubber Wear testing machine

- 4Basic Principle and Application Analysis of Asphalt Wear testing machine

- 5Basic Principle and Application of Lubricating Oil Wear Resistance Tester

- 6Working principle and application of UV coating Cupping testing device

- 7Application of shakeout Tester in organic polymer film abrasion resistance testing

- 8Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 9Paint film abrasion resistance and test method thereof