Germany PHYNIX surfix Coating Thickness Gauge Probe type

According to different measuring principles, PHYNIX offers various probe types:

The F-probe (ferromagnetic - blue nozzle) using the magnetic induction measuring method (DIN EN ISO 2808/2178 and ASTM B499) is used for measuring magnetic substrates such as iron and steel.

The N probe (non-ferromagnetic - yellow nozzle) using the eddy current method (DIN EN ISO 2808/2360 and ASTM D1400) is used to measure non-magnetic conductive base materials such as aluminum, zinc, copper, etc.

FN probe (combination probe - green nozzle), suitable for measuring magnetic and non-magnetic substrates such as iron/steel and non-ferrous metals. Automatic selection of the suitable measuring principle for the substrate.

standard probe

All of our standard probes for layer thickness measurement have a hard, wear-resistant measuring stem that ensures a very long service life. The probes are designed for measuring ranges up to 1,500 μm. Measurements are possible using the magnetic induction measuring method and the eddy current method:

For non-destructive coating thickness measurement on steel, the magnetic induction principle is used. Coatings need to be non-magnetic - eg, varnish, paint, enamel, plastic, glass, aluminum, lead, chrome, copper, brass, zinc, tin, etc.

The eddy current principle enables non-destructive coating thickness measurements on non-magnetic metallic substrates, eg. Aluminum, aluminum alloy, lead, bronze, copper, brass, zinc, die-cast zinc, tin. Coatings to be tested need to be electrically insulating; for example, varnishes, paints, enamels, plastics, glass, anodized coatings and ceramics

The plastic feet on the bottom of the probe are additionally provided with V-grooves. Thus, vertical positioning on cylindrical or curved surfaces is facilitated. With optional thermal measurement mounting feet, coatings up to 150°C can be measured. A high-temperature base is also available as an accessory, allowing measurements even on surfaces up to 300°C.

| probe style | Probe introduction |

| Probe FN 0.2 High-precision probe, especially suitable for measuring thin layers in the range of 0-200μm. Combination probe for measuring iron/steel and non-ferrous metals. The adjustment to the corresponding substrate takes place automatically. |

| Probe FN 1.5 Standard probe with a measuring range of 0-1,500 μm. Combination probe for measuring iron/steel and non-ferrous metals. The adjustment to the substrate takes place automatically in the measuring instrument. Acid resistant rods are also available. |

| Probe F 1.5 Standard probe with a measuring range of 0 - 1,500 μm. For measuring iron/steel. |

| Probe N 1.5 Standard probe with a measuring range of 0 - 1,500 μm for measuring non-ferrous metals. In the version with acid-proof rod, the probe is especially suitable for electroplating equipment. |

special probe

Special probes for coating Thickness Gauges can measure unusual coatings on many different base materials. Choose from seven models according to application and requirements designed as F probe (magnetic induction), N probe (eddy current) or FN combination probe (both principles):

| probe style | Probe introduction |

| Probe FN 1.5 / 90° The tube probe has a measuring range of 0 - 1,500 μm. Especially suitable for coating thickness measurement in holes, pipes and grooves. With this probe, coating thickness measurements in difficult-to-access areas are possible with high measurement accuracy. The newly developed deflection suspension of the sensor head results in very small measurement uncertainties and high reproducibility of measured values. For measuring iron/steel and non-ferrous metals. Pipe probe with a measuring range of 0-1,500 μm. Specially developed for layer thickness measurement in holes, pipes and grooves. With an immersion depth of Ø13 mm and an insertion length of 165 mm, high-precision coating thickness measurements are also possible in hard-to-reach locations. Very low measurement uncertainty and high reproducibility are achieved by the elastic mounting of the sensor head. For measuring steel and non-ferrous metals |

| Probe FN 1.5R Rectangular probe with a measuring range of 0 - 1,500 μm. The rectangular position of the sensor head enables measurements in hard-to-reach areas. For measuring iron/steel and non-ferrous metals |

| Probe F 1.5R Rectangular probe with a measuring range of 0 - 1,500 μm. The rectangular position of the sensor head enables measurements in hard-to-reach areas. For measuring iron/steel |

| Probe FN 3.5 Rectangular probe, measuring range from 0 - 3,500μm to iron/steel and 0 - 3,000μm non-ferrous metals. Also used for measurements in hard-to-reach areas. |

| Probe F 3.5 Probes with a measuring range of 0 - 3,500 μm covering common measuring tasks. For measuring iron/steel |

| Probe F 10 Rectangular probe with large measuring range 0 - 10 mm. For measuring iron/steel. |

- 1PHYNIX Coating Thickness Gauge measurement principle

- 2Germany PHYNIX Coating Thickness Gauge FAQ set

- 3Elcometer 456 Coating Thickness Gauge

- 4Elcometer 355 Coating Thickness Gauge Iron and non-iron based probe selection table

- 5American Defelsko PosiTector 6000 Coating Thickness Gauge probe characteristic parameter selection

- 6Defelsko PosiTector6000 Series Coating Thickness Gauges

-

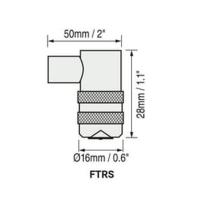

Defelsko FTRS Thickness Gauge Probe$ 904.00

-

-

-

-

-