What is equilibrate moisture content and why is it important?

In many different industries that involve the use of wood or other moisture-absorbing materials, you may hear the term "EMC" mentioned from time to time. While the term is very familiar to industry veterans, it may not be familiar to those new to the woodworking, flooring or restoration trades.

So, what is EMC, and why is it important to someone who works with wood regularly?

Define EMC

The term "EMC" is an acronym for Equilibrium Moisture Content. The term is often applied to "hygroscopic" materials, such as wood. The term "hygroscopic" refers to a material that absorbs moisture from the atmosphere or releases moisture into the atmosphere until equilibrium with the surrounding environment is achieved.

For the woodworking industry, equilibrium moisture content is defined as the point at which wood stops absorbing moisture or releasing moisture into the surrounding air. At this point, the material is said to have reached equilibrium with the atmosphere.

So why is EMC important to carpenters, flooring contractors and restoration professionals?

Why EMC is important

For anyone who works with wood products regularly, there are several reasons why it is important to know that wood has reached its EMC, which will be affected by the average moisture content of the area where the wood is located. used.

First, when wood absorbs or releases moisture, it expands or contracts. The more moisture absorbed or released, the more the wood product will expand/shrink.

For example, let's say you're installing a set of wood floor planks on a job site with an average moisture content of 11%, which indicates a humid environment. However, the planks were initially adapted to areas with an average moisture content of 6%, indicating a drier environment.

When exposed to "humid" conditions, the planks will begin to absorb moisture from the air and swell slightly. This can cause the installed planks to begin to cup or warp as their expanding mass pushes against other planks - causing damage to the floor and ruining its appearance.

Check the EMC in the wood and the average moisture content of the structure/area

So, how do you check wood for EMC? A good practice is to check the %MC of the wood several times over a period of several days in the installation environment. Using a wood Moisture Meter, read the moisture content of the wood every few hours until the %MC reading stops changing.

Depending on the wood's original moisture content, the temperature of its new environment, and the relative humidity of the area, it may take several days for the wood to fully acclimate to a particular environment. In general, the greater the difference between the moisture content of the wood and the EMC point of the wood, the longer it will take to fully acclimate.

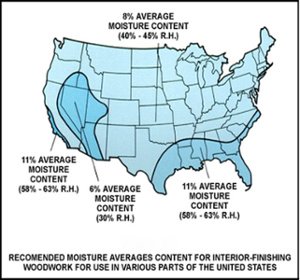

Now, you might be wondering how to determine the average moisture content of an area. If you look at a map of the US here, you can see that most of the US has an average moisture content of 8%, while some coastal areas have an average moisture content of 11%, and drier desert areas are closer to 6%.

Now, you might be wondering how to determine the average moisture content of an area. If you look at a map of the US here, you can see that most of the US has an average moisture content of 8%, while some coastal areas have an average moisture content of 11%, and drier desert areas are closer to 6%.

While this will give you a general idea of what to expect, it may be necessary to get more detailed information by taking an RH measurement of the area where you are installing the wood.

To get relative humidity (RH) readings, you need a thermo-hygrometer that can measure the temperature and humidity conditions of a large workplace. The RH reading you get from your Moisture Meter can help you understand what the EMC of the wood product on site should be.

For example, if your RH reading is between 58% and 63% RH, then your average moisture level is about 11%.

Detailed humidity information such as RH and EMC helps you make more informed decisions in carpentry, flooring installation and restoration, avoiding costly mistakes.