Moisture meter FAQ and answer

Today, we would like to address some common questions users have about wood Moisture Meters. Some of these questions come from those who are just starting out with wood hygrometers,

While others are from more experienced users looking for detailed tips:

Question 1: Why should I use a wood Moisture Meter?

This is probably a commonly asked question among first-time hygrometer users. While specific answers to this question may vary by industry, those answers are often related to quality.

Using a wood Moisture Meter, you can accurately assess the problems that a given sample of wood may be experiencing, such as cracking, shrinkage, splitting, mold growth, and more. When the moisture content of wood is too high (or even too low, in some cases), the quality of the final product can suffer.

Using a Moisture Meter will help you ensure that the moisture content of the wood material you are using is within the correct %MC range to avoid future callbacks.

Question 2: What are the different types of wood Moisture Meters?

While there are countless hygrometer models on the market, and new ones appear all the time, they fall into two categories based on their operation:

Pitch.

Needle-free rice.

A pin hygrometer uses two (or more) electrodes to penetrate the wood material to read the %MC of that material using the principle of resistance. In a two-pin meter, one pin sources current and the other receives current, and the meter interprets the resistance of the current against the current. Since wood is an insulator and water is a conductor, the less resistance to electrical current, the higher the wood's moisture content.

Pinless meters, on the other hand, use electromagnetic radio waves to scan a sample of wood beneath the meter scan plate. These gauges are sometimes called non-intrusive Moisture Meters because they don't have to physically penetrate the wood surface to get a reading.

Question 3: Which type of moisture analyzer is better?

After asking about the different kinds of Moisture Meters, most people also want to know which Moisture Meter is the best type. The answer depends largely on the type of work you're doing, the size of the wood material you're working with, whether you're leaving pinholes in the material, and your personal preference.

The needleless meter is fast and will not damage the surface of the material being scanned. Pins, on the other hand, can give you more specific information about the moisture distribution in the wood.

Many professionals use both types of meters in their work, switching between the two as necessary.

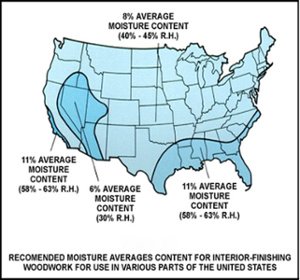

Question 4: What is the correct %MC for wood?

The answer to this question depends on the end use of the wood and where it goes. For furniture and flooring applications, most woods should have a %MC between 6% and 8%. However, certain areas of the US may require drying to different %MC levels.

Question 5: How to determine the distribution of moisture in the circuit board?

To determine the distribution of moisture in the board, you'll need a pin type meter with insulated pins (non-insulated pins can be used, but insulated pins make this easier).

First, remove the meter's pins and gently push them into the material to be measured. Read the "shell" or outer layer of the board. After taking a reading, push the pin in 1/16 inch increments to take a new reading at any time. By recording moisture readings of the board at various depths, you can get a good indication of the distribution of moisture in the board.

Why not use a needleless meter? Because the pinless gauge can read the humidity of the entire area and the depth with a single digital scan, there is no way to isolate the depth at which moisture is present.

Question 6: Does temperature affect the accuracy of meter readings?

The short answer is yes, but usually to a very small extent in needle gauges. As the temperature of the wood increases, its electrical resistance decreases, resulting in an increase in the indicated %MC for this sample. For field conditions, if the temperature of the wood sample tested is between 50°F (10°C) and 90°F (32.2°C), there is no need to correct the temperature readings.

The short answer is yes, but usually to a very small extent in needle gauges. As the temperature of the wood increases, its electrical resistance decreases, resulting in an increase in the indicated %MC for this sample. For field conditions, if the temperature of the wood sample tested is between 50°F (10°C) and 90°F (32.2°C), there is no need to correct the temperature readings.

When measuring wood materials that exceed these temperature values, and the meter itself does not have a built-in temperature correction, you can use the temperature correction chart to find the correction (Delmhorst provides these with every hygrometer).

Needleless meter readings do not measure electrical resistance, so their readings are not affected by the temperature of the wood unless the sample is completely frozen.

Question 7: How do I correct readings for different species of wood?

With pin and pinless Moisture Meters, the type of wood will affect the readings you get. For pin gauges, the difference in readings is due to the different inherent resistive properties of different species of wood. For pinless gauges, the specific gravity (SG) of the wood will affect the reading.

Each Moisture Meter is usually calibrated using a specific species of wood, such as Douglas fir or oak, which makes the meter accurate for that type of wood but less accurate for others.

In general, there are two ways to correct readings for a given species of wood:

Use the species correction table provided by the meter manufacturer.

Use a meter with built-in species correction.

Using a meter with built-in correction is often easier and faster than referring to a manual and doing the math yourself.