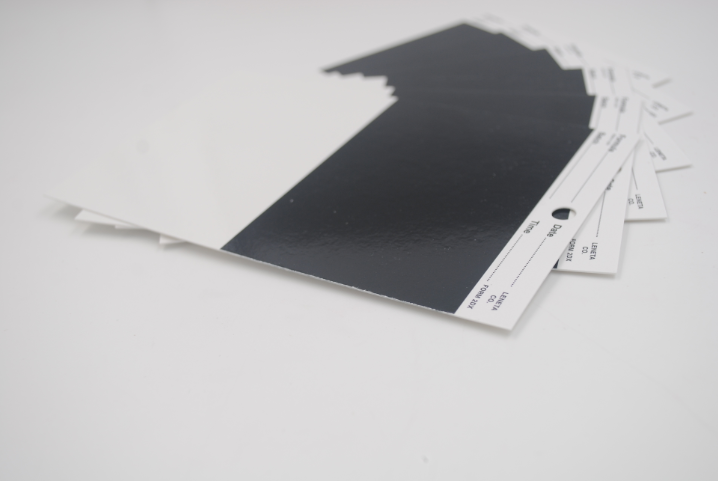

Seven advantages of Leneta covering power cardboard

1. The surface is smooth. Most leneta opacity cardboards are laminated on both sides, which is smoother and less textured than the single-sided laminated cardboards used previously. The prepared film has a more uniform surface and less orange peel.

2. Not easy to curl. Cardboard coated on both sides is more resistant to curling under normal temperature conditions and the reduction of water-based coatings.

3. No fluorescent agent (no fluorescent whitening agent). Leneta cardboard does not add any fluorescent whitening agent, the addition of fluorescent whitening agent will affect the instrument or visual evaluation of color results.

4. Adhesion. Leneta cardboard has good structural integrity for ink on paper, which can be an advantage when testing paint adhesion on the cardboard surface.

5. Anti-penetration. Leneta cardboard is water resistant to solvent or water soluble paints. No pimples, no cracks, no cracking.

6. Wettability. The clear topcoat on the surface of Leneta cardboard is specially designed to provide good wetting. No cracks, no pinholes.

7. Uniform color. Y-reflection in black and white areas is strictly controlled to meet industry standards. A high level of color consistency between and within batches was maintained.

The high quality of Leneta jams increases the reliability and repeatability of your tests

- 1Summary of determination methods for hiding power of coatings

- 2Pigment hiding power

- 3Determination of Coating hiding power

- 4GB/T 23981.2-2023: Paints and varnishes - Determination of hiding power - Part 2: Checkerboard method - Interpretation

- 5Concept, influencing factors and determination method of Coating hiding power

- 6Mayer Rods: The right-hand man for hiding power tests

- 7Coating performance testing: ensuring the efficiency and mass of the painting process

- 8Coating hiding power measurement

- 9Application of paint film Applicator in hiding power test

-

-

Leneta WB sealed film, pure white$ 298.00

-

-

Leneta Form 2C Opacity Chart$ 306.00

-

-