How to choose pre-film film laminating equipment?

At present, there are many types of equipment for pre-coating films. Theoretically speaking, if the temperature of the heating roller can reach above 85°C, the adhesive layer of the pre-coating film can be melted. The melted adhesive layer has certain precision and can be combined with other materials. There are many factors to be considered in the actual selection of pre-coating film equipment. The following points need to be paid attention to:

Uniformity of heating drum temperature

At present, the laminating part of most of the laminating equipment in CHINA is composed of two parts: one is the heating steel main drive roller with a constant position, and the other part is the driven roller that adjusts the distance mechanically or hydraulically and contacts the steel Heat-resistant rubber roller. The temperature requirements of the pre-coating film on the heating roller can be adjusted with the change of the coating speed, and the temperature range of the heating roller is small whether it is in the axial direction or in the radial direction.

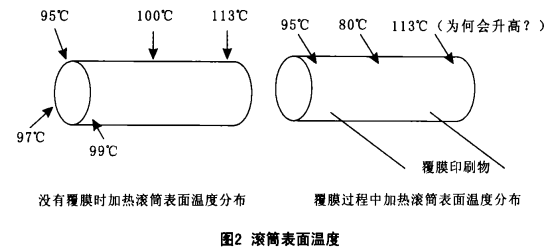

However, the heating method of the heating roller in actual production is to use electric heating tubes or quartz tubes. These electric heating tubes or quartz tubes are fixed inside the heating roller, relying on heat radiation and air conduction to the wall of the heating roller, and then transfer heat to the surface of the roller. . Under the condition of no coating, most of the temperature on the surface of the detected drum is shown in Figure 2. The temperature difference in the circumferential direction is 3°C~5°C, and the temperature difference in the axial direction is 5°C~15°C.

During the film covering process , the temperature of the surface of the heating roller with the film passing through and the surface without the film passing through is very different. It is often when the film temperature is sufficient on the surface, but the phenomenon of filming occurs when the film is rolled and four-convex after the film is covered . Because the sensor for detecting the heating roller is fixed on the edge of the heating roller, and the temperature seen by the operator is not the real temperature of the film , which will bring confusion to the operator, salesperson , and management personnel, so pay attention to the surface of the roller Temperature equalization is very important (the sensor is better placed close to the middle surface).

The coating strength of the pre-coated film on the left side of the drum to the printed matter is not as good as that on the right side. This is because within a certain range, a higher temperature can make the adhesive layer of the pre-coated film soften more fully, the molecular thermal movement of the adhesive layer is intense, and the surface binding force with the printed matter is strong.

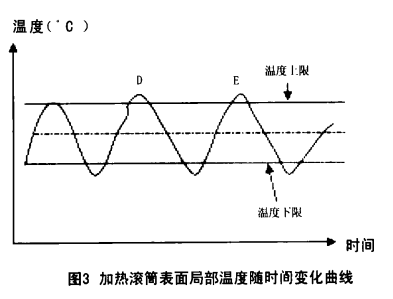

At present, the local surface temperature of the drum using electric heating changes with time , as shown in Figure 3.

The results of local area inspection can be represented by the above-mentioned changing curves. If the dotted line in Figure 3 is defined as the temperature setting curve, then upper solid line in the figure is the upper limit of the temperature of the pre-coating film, and the lower solid line is the temperature lower line that the pre-coating film can withstand Considering the temperature considering the minimum temperature (lower solid line) required by the film process , the temperature condition of the coating should be between the two solid lines to be meaningful.

When the film temperature is higher than the upper solid line (that is, the D and E areas in the figure), it will cause:

(1) Decomposition of the adhesive layer of the pre-coated film, manifested as blistering after coating. This is because the adhesive layer is a high-molecular polymer material at a low temperature. If it exceeds 130°C, small molecules will decompose into gas to form bubbles, and moisture or volatile substances in the printed matter will also form gas, which will bulge the film and form a release phenomenon. .

(2 ) The matt effect becomes worse (the surface develops towards the brightness level). This is because the matt layer is a mixture of propylene, ethylene, and butene. The temperature resistance of ethylene materials is low, and the transparency effect is enhanced : at the same time, the uneven surface that causes the matt effect becomes flat under the action of temperature and appears. A light effect.

(3) There are spots on the surface of the glossy film (caused by the precipitation of additives). The antistatic agent in BOPP film precipitates faster at high temperature, and the precipitated substance sticks to the steel roller, and the fouled heated steel roller contaminates the surface of BOP, resulting in a decrease in surface permeability and gloss.

If the coating temperature is lower than the temperature indicated by the lower solid line, the following phenomena will occur:

(1) The film strength is low. In the areas A, B, and C in the figure below the lower line of the coating temperature, the coating is less than half degree bonded. Although it is sometimes invisible from the appearance, if the film-coated product is subjected to four-convex and rolling operations at this time, filming will easily occur in the deformed area.

(2) The printed product is not clear, and the hot melt adhesive cannot be fully melted in the area lower than the coating temperature, resulting in a decrease in the transparency of the polymer

From the above analysis and practice, we can see how important the influence of temperature on the quality of the pre-coating film is, so film processing enterprises should pay attention to this issue. It is most preferable to heat the drum with a hot solution. Currently there are generally two

Way: one is to use superheated water to heat and the other is to use heat-conducting kerosene. Since the high-speed flowing constant-temperature liquid can quickly replenish the heat taken away by the coating, the temperature constant, and is not affected by whether the drum is running or not.

Surface condition of steel drum

For traditional oil-based or water-based films, the higher the surface finish of the roller, the better . Because the smoother the surface of the roll, the better the surface gloss of the BOPP after coating. But such rolling is not suitable for pre-coating film, because of the difference in process temperature between the two. When the pre-coating film is applied, the surface temperature of the roller needs to be around 110°C . At this temperature, as the processing progresses, the roll-off performance of the film after coating is poor, and the coated product is not easy to detach from the hot roll. Therefore, the surface of the steel roll used for pre-coating film coating should be fine and rough, so that when the film is coated , there will be air sandwiched between the hot roll and the surface of the BOP film, and the roll-off property of the coated product will become better.

The surface state of the steel drum also includes surface defects such as no pits, drums, and scratches on the surface . The steel heating roller is like the printing cylinder of the printing machine , any defects on the surface will be copied to the surface of the film-coated product, so the heating roller needs to be well maintained to prevent the surface from being damaged.

Uniformity of rubber roller

People who are new to pre-coating film often tend to ignore the role of rubber backing rollers. In the case of pre-coating films, the uniformity includes two items: uniformity of shape and uniformity of material.

The uniformity of the dimensions of the rubber backing roller means that the geometric dimensions must be the same as other points. This requires that the diameter of the drum is consistent, and there are no surface defects on the surface of the drum. Inconsistent diameters, especially when the diameters at both ends of the rubber roller are different, will lead to differences in the amount of paper feeding. The larger the diameter, the larger the amount of paper feeding, and the smaller the amount of paper feeding. This will cause the paper to be twisted and wrinkled. The surface of the product is completely destroyed.

If there are pits, drums, scratches , it will also affect the effect of the coating like the surface defects of the heating roller, but the degree of influence is smaller than that of the heating steel roller . At the same time, the effect of the film also depends on the thickness of the paper of the laminated printed matter . The thicker the paper, the more severe the effect.

The uniformity of the material of the rubber roller, more generally speaking should be the uniformity of the hardness of the rubber roller . It also requires that the hardness of any point is the same as that of or the difference is within the range that does not affect the coating effect. If the hardness difference is large, under the same pressure , the film fastness of the area with high hardness is stronger than that of the area with low hardness, resulting in uneven and affecting the final film effect.