What is film laminating? Advantages of pre-film film laminating

Lamination is to bond plastic film (usually BOP, BOPET, BOPA and its derivative film) to a certain substrate (usually printing paper, cardboard, plastic film ( plate), metal plate (foil), wood plate, ceramic plate, etc.) process. At present, it is common for the lamination of printed paper products, and the downstream industries involved are books, various packaging boxes, handbags and other printing and packaging fields. The coating of brushed paper products is to compound BOPP, BOPET, BOPA and other films on the printed paper and paper plate through adhesives, so as to decorate the printed matter (brighter, matte effect, hand feeling effect), improve strength, and protect ( Waterproof, oil-proof, scratch-resistant).

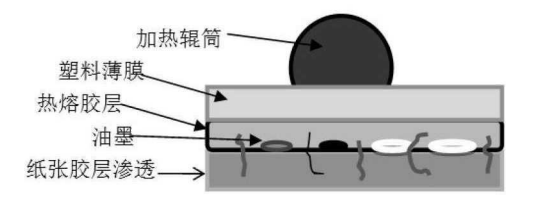

Due to the different sizing methods, the film can be divided into immediate coating film and pre-coating film. That is to say, the coating film is sizing at the filming site, coating the surface of the film with liquid glue, and then compounding it with printing paper after drying : the pre-coating film is coated with hot melt adhesive on the top of the plastic film , A lamination process in which the film and the printed paper are bonded together by applying heat and pressure at the lamination site .

The pre-coating film coating process began in the 1980s and was introduced to CHINA at the end of the last century. However, the market share of the film coating at that time was less than 1%, and at the same time, the country itself hardly had the production capacity of pre-coating film. Since the beginning of this century, private enterprises have started to produce pre-coated films . By the end of 2016, an annual production capacity of 200,000 tons has been formed . According to the information provided by CHINA Printing Technology Association, domestic pre- films have occupied the total Nearly 30% of the market share, and it is still growing. The reasons for the rapid development of pre-coating film coating are as :

1. The process is simple, only temperature and pressure are needed to complete the film coating, eliminating the need for sizing and drying processes, so the film coating equipment is simpler than the same level of instant coating equipment, and easy to operate and control

2. High film lamination efficiency, can carry out lamination production at high speed

3. It can be operated at any time and stop laminating immediately. That is, it is suitable for mass production, and is more suitable for switching between multiple varieties and small batches at any time, which is consistent with the current batch characteristics of printed matter:

4. Since there is no on-site liquid sizing process, it saves a lot of complicated cleaning work and is welcomed by practitioners:

5. Energy saving , raw material waste

6. Relatively low requirements for the skill level of practitioners

7. Environmentally friendly, there is no peculiar smell at the work site, no discharge, hygienic and safe

8. Excellent film quality, less quality accidents, what you see is what you get (What' s you look, What' s you get)

9. A wide range of laminating equipment can be selected, which expands the application range of pre-coating film;

10. The continuous lightweight of pre-coated film makes it go down from the high price situation, and the cost difference between the pre-coated film and the water-based film is getting smaller and smaller. Even so, in the actual pre-coating film processing process, due to the quality of the pre-coating film itself and the operator's inattention, the pre-coating film coating will also have film quality problems, such as insufficient lamination lath. , The surface is wrinkled, there are bubbles after the film is covered, the surface of the film is not clear, etc. Among them, the technical reasons for the insufficient film fastness are worth studying and should attract the attention of pre-coat film manufacturers and film practitioners. The film fastness is the bonding strength, or adhesion, between the plastic film and the covering material.

The film fastness is the bonding strength between the plastic film and the covering material, which is called adhesion.

Adhesive principle of pre-coated film lamination:

As shown in the picture above, the heating roller simply transmits heat to the adhesive layer through the plastic film, and the melted hot melt adhesive will bond the ink and penetrate into the pores of the paper to form the film fastness.

After experience accumulation and data analysis, the reasons for the insufficient film fastness of the pre-coating film are related to the following factors: 1 The structure of the pre-coating film, including the type of substrate, the nature of the adhesive layer, and the thickness of the adhesive layer 2. The temperature of the coating film : 3. Laminating pressure: 4 Laminating speed: 5. The nature of the ink, the degree of dryness: 6 The nature and moisture content of the paper: 7 Environmental temperature and humidity.