Application of RCA paper tape wear resistance test in wearable equipment decorative film wear resistance test

Wearable devices and products are mostly common items that people carry with them, and they will inevitably collide and rub against various items in life. Therefore, the wear-resistant and scratch-resistant performance is another basic performance to ensure the long-term use of decorative films. Abrasion resistance is related to film structure, composition, crystal orientation and film thickness, etc. In industry, there are different , mainly including shock plate test and barrel grinding. Test, tape wear test, etc. Scratch resistance mainly focuses on the surface hardness of the film layer. Pencil hardness test and microhardness test are commonly used .

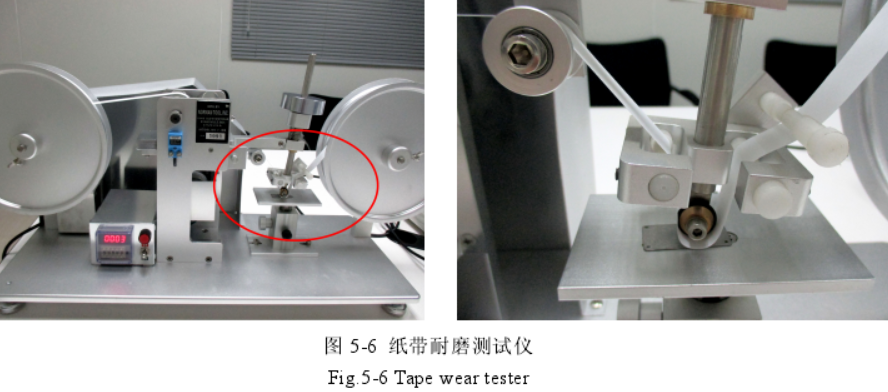

Paper Tape Abrasion Test

The RCA paper tape wear test uses a special wear Tester and a special paper tape for testing, simulating a mild and long-lasting wear-resistant environment, and verifying the long-term wear resistance of the wearable decorative film. The test method is as follows: 1) Use a special wear Tester and paper tape, and select an appropriate load according to the actual situation; 2) Put the sample to be tested into the bottom of the paper tape (as shown in Figure 5-6); 3) Turn on the instrument , the turntable drives the paper tape to rub the surface of the sample continuously for a specified number of laps (PVD coating generally chooses 200 laps); Note: This experiment needs to be carried out in a room at room temperature with a humidity of 40%~60%; the paper tape is stored at 40%±5 % humidity, in an environment of 24°C±2°C.

The results of the paper tape wear test showed that after the paper tape wear test, there were friction marks on the surface of the film layer, but there was no whitening.

- 1Working principle and application of UV coating Cupping testing device

- 2Application of shakeout Tester in organic polymer film abrasion resistance testing

- 3Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 4Paint film abrasion resistance and test method thereof

- 5Polyethylene (PE) coating indentation hardness inspection and its importance in pipeline corrosion protection

- 6Paint film abrasion resistance and its test method - rubber abrasive wheels method

- 7Determination of abrasion resistance of paint film

- 8Determination method of paint film abrasion resistance and its importance

- 9Coating performance testing: the key to ensuring quality coatings