Why choose Mayer Rods Moulding for multi-layer films?

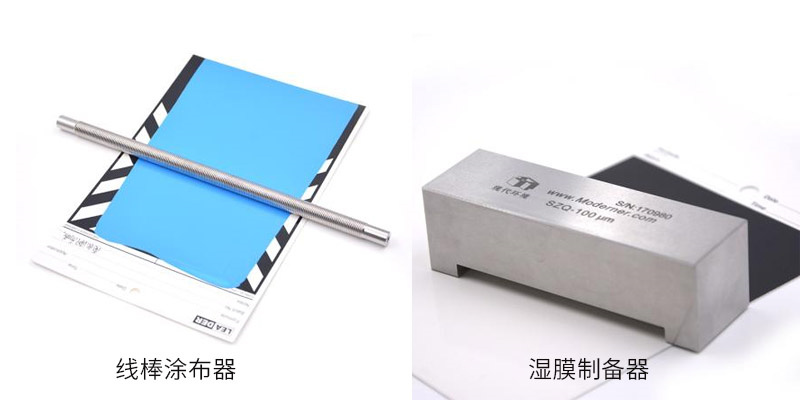

In coating film performance testing experiments, the most commonly used manual coating tools are wire Bar Coaters and wet film preparers. Although they are both preparation tools, the difference in application between the two is relatively large. For example, the wire rod is more advantageous for fine coating and thin film coating; while the Wet Film Applicator is more advantageous for high viscosity and wear-resistant coating experiments. Today is mainly to analyze which coating tool is more suitable for multi-layer coating in the coating experiment?

In the experimental performance testing of some coatings, such as some water-based coatings, it is often necessary to apply multiple layers of coatings on the same substrate to test different properties. It is necessary to carry out primer coating, intermediate coating and top coating, and the film thickness of different layers of coating film is not necessarily the same.

Due to the great difference in appearance and shape between the wire Bar Coater and the wet film preparer, and because of its appearance design, the wire Bar Coater is generally selected for multi-layer coatings instead of the wet film preparer. . why? Please see the picture below

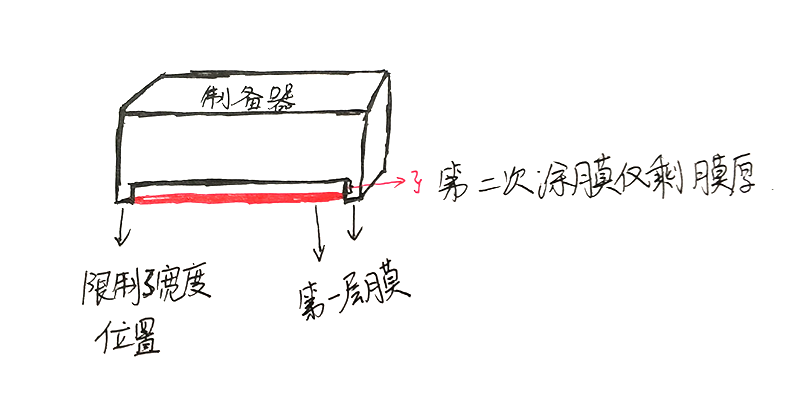

Let's talk about wet film preparation first. The appearance of the wet film preparer is a work-type. During the film coating process, the protruding parts of both ends need to be pressed on the substrate for coating. The thickness of the film prepared by the preparer is fixed. There is already a certain film thickness. If you want to apply a second film on the same place, you will not be able to apply the same film thickness.

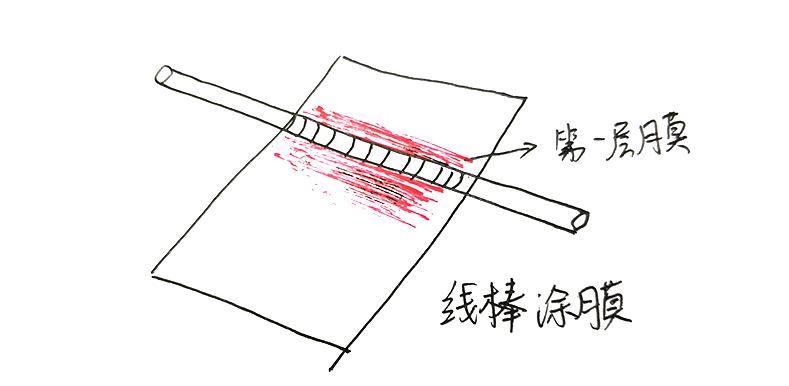

In addition, for the wire Bar Coater, the wire Bar Coater is a straight rod, the thickness of the coating film is fixed, but the two ends of the coating are not limited, and the coating film is relatively free. Therefore, the multi-layer coating film can be completely held, and the second coating film on the first layer of dry coating film is equivalent to applying a new layer of coating film on a thickened substrate, and the film thickness is completely different. restricted.

In fact, from the appearance and coating principle of the two film-making tools, it is not difficult to see that the wire Bar Coater is more flexible and free on the coating film. Therefore, for multi-layer coatings, wire Bar Coaters are generally selected for coating and film formation.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Wire Bar Applicator rod and wet Film Applicator difference video tells you

南北潮

- 6Application of Mayer Rods in Water-based ink Moulding

- 7Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 8Principle, Application and Type Selection of Drying Agent Film Applicator

- 9Principle, Application and Selection of Undercoat Film Applicator