Operation Instructions for Pushen 339 Wear Resistance Testing Machine

1. Before the test, first remove the paint debris left by the previous eraser with coarse sandpaper

2. If you need to change the test equipment, you can replace the friction head under the sliding rod

3. Place the weight of the specified weight on the friction rod

4. The sample to be tested needs to be clamped and fixed on the test position

5. Before turning on the power, you need to set the number of counters, which can be adjusted from 0 to 9999 times. If the counters are all reset to zero, the machine will not work

6. Adjust the number of tests and speed 0~60 rpm

7. When the counter runs and rubs to the bottom part, immediately turn off the motor speed, which is the number of wear resistance

8. If you need to pause or return to zero, just turn off the speed switch

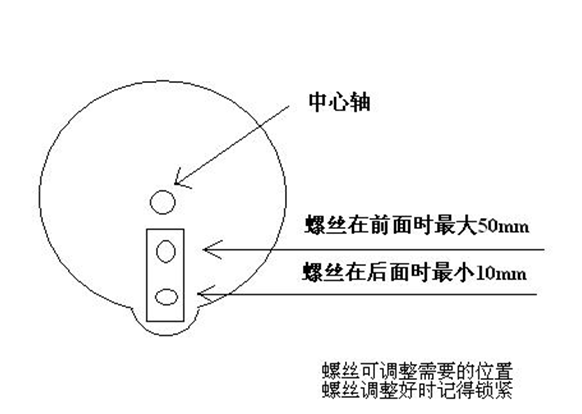

9. The test rod can be adjusted to the required position according to the height of the sample

10. The minimum friction distance required for adjustment is 10mm and the maximum is 50mm

11. If you need to adjust the friction distance, seal the back of the machine, remove the screw on the central axis under the motor, loosen and adjust the required distance, and then tighten the screw PS: Be sure to lock the screw

*When maintaining, please remove the rear cover plate of the machine, and add oil to the slide rail under the motor. When not in use for a long time, please turn off the power

*If the machine cannot be activated, please check the following items for troubleshooting:

(1) Whether the counters are all reset to zero

(2) Is the motor speed switch off?

(3) Whether the fuse inside the main power switch is damaged

(4) If the motor speed slows down, the motor carbon brush needs to be replaced

- 1How to test the different properties of rubber?

- 2How to install and use the domestic TABER wear-resistant testing machine?

- 3Operation Manual of Asiri Taber Wear Tester

- 4Main performance characterization and influencing factors analysis of lame plating polyurethane elasticity wear-resistant materials

孟庆莉;崔洪犁;吴文文;刘东晖 - 《聚氨酯工业》

- 5NOX_1 high temperature strong anti-corrosion coating powder

虞子森;葛伟敏;蔡正燕;贝祖建 - 《精细与专用化学品》

- 6Differences between imported and domestic (CN) Abrasion Tester

- 7What should be paid attention to in abrasion test?

- 8Determination of wear resistance of films with TNNN-4 Tester

-

-

-

-

-

-

FARI FR-1907 TABER Abrasion Tester$ 1559.00