Why does RDS Mayer Rods, with 80 + years of technical experience, have a good reputation?

The Myler rod is widely used in the laboratory to prepare precise film layers, and it is one of the three mainstream coating methods today. American RDS is one of the well-known wire rod brands at home and abroad. It was founded in 1936 and has 80+ years of industry technical experience. It has been introduced to CHINA for more than 30 years and is widely used in 50+ domestic subdivision industries. RDS coating rods are used in sample preparation instruments in dozens of academic papers.

RDS wire rod coaters are used in thousands of pieces every year in CHINA. Its application industries include but are not limited to dozens of industries such as coatings, inks, films, tapes, wallpapers, and varnishes.

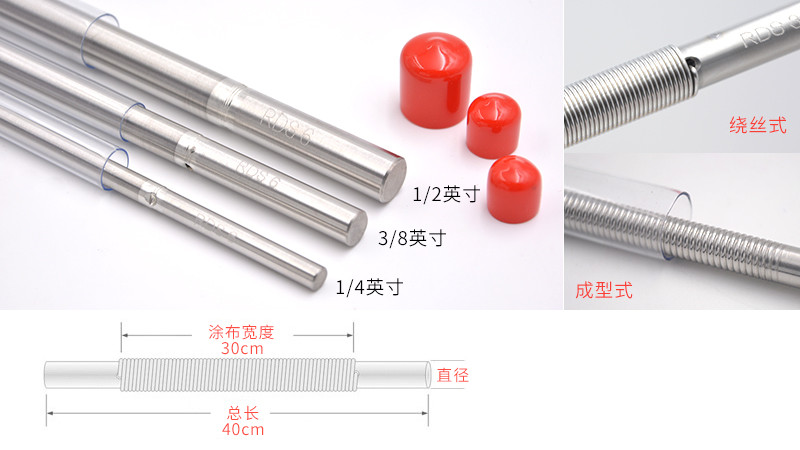

American RDS wire rods provide a variety of options in terms of process types and specifications to meet the needs of users in different industries. The wire rods used in the laboratory are uniformly 40cm long and the coating width is 30cm.

● In terms of diameter, there are three different diameters: 1/4'' (6.35mm), 3/8'' (9.5mm), and 1/2'' (12.7mm).

● In terms of process types, there are wire-wound, extruded, double-wound, and open-ended. Domestically, 9.5mm wire winding rods and 6.35mm forming rods are mostly used. The former is mainly a habit, while the latter is due to hardening of some coated substrates or concerns about broken wires caused by misuse, improper cleaning and bumps (probability 2 ‰, northern and southern tide statistics)

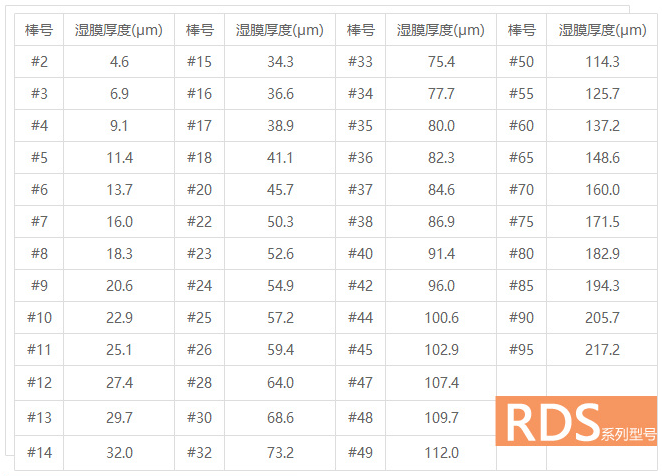

● In terms of film thickness selection, 4.6~217.2μm can be prepared, and more than 50 models are available.

The reason why RDS coating rods are widely favored by users in the industry and have a good reputation is the accuracy of the coating film, the scraping effect and the advantages of materials. This is also the core focus of industry users when choosing wire rods.

Good 304 stainless steel and strong winding wire make it have an advantage in the field of winding rods. Because the wire rod of the wire winding is prone to the problem of wire breakage, especially the wire rod with a fine wire diameter, because the requirements for the workmanship are very high. However, judging from the usage situation of the users of the Northern and Southern Tide, the problem of broken wires is less than 2/1000.

In addition, the coating film precision as high as 0.1 micron also makes it the first choice for users in the preparation of Chaobo film. NBCHAO has done experiments to compare the coating effect of RDS wire rods with other domestic brands, and shared a report - " Experimental data tell you what is good about RDS wire rods?" "

Let’s share the RDS coating operation video below, and you can feel the fineness, smoothness and uniformity of the coating film.

While RDS has its unique advantages, it also has its disadvantages, that is, the uniformity of coating length. The RDS wire rod coaters in the laboratory are uniformly 40cm long and 30cm wide. At present, the coating width actually required by some users only needs to be about 25cm, or even shorter as long as 6cm, in order to reduce the experimental cost or meet the coating experiment with a limited coating length.

But in any case, RDS wire rod is still a coating rod brand with a good reputation in the industry and is widely recognized by industry users. To sum up, the reason why Beichao recommends RDS wire Bar Coater is mainly due to several considerations:

1. RDS wire rod coater has a history of more than 80 years in the industry, needless to say the technical experience. And it is also recognized by industry users.

2. Its high-precision coating film, firm winding wire and wear-resistant material make it have a longer service life and better coating effect.

3. The diversification of process, film thickness and diameter can meet the needs of different users.

4. The price is in the middle of the same imported brand, and the price is high!

The author of this article: NBCHAO Mall, reprinting is strictly prohibited

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets