Hardness measurement of coating applications

introduce

The hardness of a coating material is a relative property that can be explained in various ways by the different industries using the coating/lining material. While hardness tests are often used to assess the degree of cure, they can also be used to measure hardness characteristics formulated into coatings. Absolute hardness of the coating is not always the ultimate goal of the formulation, and an increase in hardness can be accompanied by a decrease in brittleness or flexibility of the coating. The balance of hardness with other final film properties depends on the end use of the product.

When comparing hardness values listed on a paint manufacturer's product data sheet, this information is often considered an indication of how well it has cured and its inherent performance characteristics. Keeping soft uncured coatings can cause damage in service; for example, backfilling trenches too quickly and damaging newly applied pipe coatings that are not fully cured can adversely affect pipe integrity

This article describes two common testing methods: indentation type Tester (durrometer) and pencil hardness, which is more of a pure hardness test. The choice of test method is usually dictated by the thickness of the coating material, although variations in test thickness are permitted if useful information can be obtained. The hardness of thick film coatings (this method indicates that "thick film" is considered a minimum of 6mm or 240 mils) is usually measured using an indentation type Tester which measures indentation resistance under a specific spring force load while Films are often evaluated for hardness of coatings (reference thicknesses are not included in the method) using the pencil hardness test. Note that there is no correlation between the hardness test methods described here, and no pass/fail criteria are indicated in the corresponding ASTM standard test methods. The project specification shall indicate the minimum acceptable hardness value before the coating system is put into service. The minimum acceptable hardness value is usually determined by the coating manufacturer.

Durometer hardness measurement

Durometer hardness testing was performed according to the procedure described in ASTM D2240, Standard Test Method for Properties of Rubber - Durometer Hardness. Twelve types of measuring equipment (Types A, B, C, D, DO, O, OO, OOO, OOO-S, and R) are covered by this standard. This article describes the use of the Shore D durometer because many thick film chemically resistant coatings fall within the hardness range that the Shore D durometer can accurately measure. For softer thick film coating materials, a Shore A durometer may be more useful because of its lower spring force. Durometers with hardness values less than 20 and greater than 90 are not considered reliable according to ASTM standards, and indicate that no readings below 20 and above 90 are recorded for Shore A or Shore D instruments.

Durometer hardness testing was performed according to the procedure described in ASTM D2240, Standard Test Method for Properties of Rubber - Durometer Hardness. Twelve types of measuring equipment (Types A, B, C, D, DO, O, OO, OOO, OOO-S, and R) are covered by this standard. This article describes the use of the Shore D durometer because many thick film chemically resistant coatings fall within the hardness range that the Shore D durometer can accurately measure. For softer thick film coating materials, a Shore A durometer may be more useful because of its lower spring force. Durometers with hardness values less than 20 and greater than 90 are not considered reliable according to ASTM standards, and indicate that no readings below 20 and above 90 are recorded for Shore A or Shore D instruments.

Shore D硬度计是一种小型手持设备(图1),用于测量硬质橡胶,塑料,软金属,环氧树脂和其他涂层材料等各种材料的压痕硬度。一个小锥形压头从压脚(测试仪底座)伸出。硬度计包含一个校准弹簧,用于向压头施加垂直力。当然,固化的硬化涂层将在施加的载荷的作用下提供对压头的抵抗力。这种对凹痕的抵抗力作为硬度值显示在量具盘或数字显示器上。

待测涂层表面应清洁光滑。任何固有的表面粗糙度都可能产生错误的硬度值。

由于温度和湿度会影响硬度值,因此应在测试前测量并记录涂层表面的表面温度和周围空气的相对湿度。虽然需要通过ASTM标准报告温度和湿度数据,但是没有基于主要环境条件校正硬度值。

带有独立(远程)探头的数字硬度计(图2)正变得越来越流行。它们的使用更适合曲面,因为与标准硬度计的底座相比,测试脚的直径相对较小; 但是,探头的整个测量表面需要齐平地放置在表面上而不会摇摆以获得可靠的读数。

带有独立(远程)探头的数字硬度计(图2)正变得越来越流行。它们的使用更适合曲面,因为与标准硬度计的底座相比,测试脚的直径相对较小; 但是,探头的整个测量表面需要齐平地放置在表面上而不会摇摆以获得可靠的读数。

在使用测试块验证准确性之后,将远程探针压入涂层中,直到压脚与表面完全平坦接触并保持在适当位置。在硬度计发出单个声音信号后,它将显示一个符号,表示正在获取读数。硬度计将发出双重信号并显示测量值。

验证硬度计操作

硬度计应由制造商或其授权服务中心每年校准一次。有些甚至会提供可追溯到美国国家标准与技术研究院(NIST)等国家计量机构的10点校准认证。操作员无法校准硬度计,但应在每个使用期之前验证其是否正常运行。

测试块用于验证正确的操作。所示的组(图3)表示D标度上的硬度值25,46和75。对每个测试块进行测量,并与硬度计上显示的硬度值进行比较。如果硬度计显示的值不符合测试块值的公差(例如25 +/- 5,这意味着在测试块上显示的显示硬度值范围为20-30), 硬度计应该不得用于测量涂层的硬度,应返回制造商或服务中心进行维修和校准。

测量铅笔硬度

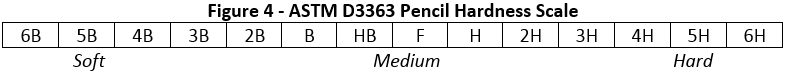

Pencil hardness testing was performed according to the procedure described in ASTM D3363, Standard Test Method for Hardness of Films by Pencil Test. Pencils containing lead centers of various hardnesses (as shown in Figure 4) were prepared and then used to attempt to scratch or chisel the coating. The coating's inherent resistance to scratch or gouging damage is an indicator of hardness. This test can be used for thin film coatings that cannot normally be evaluated using an indenter type Hardness Tester.

For pencil hardness, a series of 14 draft pencils representing various hardnesses of lead (from 6B to 6H; 4 per figure) and a piece of emery cloth or extra-fine sandpaper are required.

Remove the wood from the end of the pencil to expose at least 1/8" of the lead of the pencil. Use sandpaper or emery cloth to passivate the tip of the wire to form a 90° cylinder (rather than a conical shape that ends in a dot) (Figure 5). Hold the pencil at a 45° angle to the coated surface and try to push the edge of the blunt "cylinder" into the coated film (Figure 6). One of three results will occur:

The edge of the pencil lead will scratch but will not scrape the coating film;

The edge of the pencil lead will gouged the coating film; or

The edge of the lead will be beveled or broken, indicating that the coating is harder than the lead.

Every time a pencil lead is reused, it first needs to be "reconditioned" with an emery cloth or sandpaper to regenerate the cylindrical end of the pencil.

The pencil hardness test method indicates that the test should be carried out under the temperature and humidity conditions of 23±2°C (73.5±3.5°F) and 50±5% relative humidity. Shop/field conditions rarely meet these ranges; therefore, hardness measurements obtained outside of these conditions should be reported with actual conditions and recorded as obtained under conditions not listed in this method.

Certified pencils can be purchased, but pencil calibration is often not done because the cost of calibration often exceeds the cost of buying a new pencil. Similar to durometer hardness, the results of this method can be altered by texture or imperfections on the surface, and signs of any surface irregularities are suggested.

- 1Frequently Asked Questions about Hardness Testers in 2022

- 2Test method for roll hardness

- 3How many Hardness Testers do you know?

- 46 Tips for Using a Hardness Tester

- 5ASTM D2240 Rubber Properties, Hardness Testing

- 6ASTM D2240 Rubber Properties, Hardness Tester Hardness Testing

- 7What are the test subjects for perchlorovinyl resin anti-corrosion coatings?

- 8Controlling Variables Affecting Screen Printing Ink Deposition

- 9The principle and subdivision type of Vickers Hardness Tester