Advantages and disadvantages of roller painting method

kiss applicator

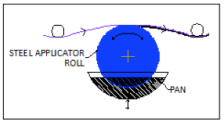

Kiss coating is a method of applying a coating to a web that "kisses" the surface of the applicator roll. Coaters generally have a relatively simple design, with a single coating roll mounted such that the bottom of the roll is submerged in the pan containing the coating (Figure 1). As the roll rotates, it takes the coating from the pan and delivers it to the web in contact with the top surface of the roll. The web usually has a minimum wrap on the roll surface, usually between 5° and 20°. The roll is driven and can rotate in the same direction as the web, in which case the coating is split between the roll and the web, or in the opposite direction, in which case all the coating is transferred to the paper web. Entry and exit idler rolls are typically provided to form the web around the applicator roll.

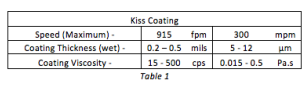

There are many external factors that affect the amount of coating transferred to the web, including the amount of coating that adheres to the web surface, web speed, web speed, web force, web wrap angle, and surface properties network of. Table 1 (below) shows typical operating speeds, coating application rates and coating viscosities for kiss coaters.

Since there are many factors that affect the coating accuracy, a coincidence coater and other methods are usually used to measure the coating amount. This can be done before the coating is applied to the web, typically by metering the coating on a touch roll with a roll or knife, or after the coating is applied to the web, via the coated side. On a mayer (winding) bar, in front of an air knife or between a set of metering rollers (fig. 1).

The kiss coater is a relatively inexpensive coater that is easy to maintain and operate. It's also easy to switch from one coat to another/clean up, especially if the coater is designed with interchangeable pans. While it has a limited coat deposit range, it is easy to vary coat weights within that range. However, it does not provide a high degree of reproducibility due to the number of conditions that can affect the deposition rate. It also has a fairly limited viscosity range and maximum speed.

extrusion roller

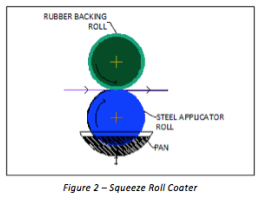

This type of coater has two rolls held together under controlled pressure. Typically, one of the rollers has a steel surface (usually chrome plated) and the other has a rubber surface. The web is passed between the rolls, usually in a straight line, and the coating is applied at the nip formed between the rolls. In many cases, the rolls are vertically configured, with the bottom roll having a steel surface and sitting in a pan containing the coating, as previously described for the kiss coater (Figure 2). As the bottom roll rotates, it delivers the coating to the nip, where a portion of the coating is transferred to the paper web. The rolls can also be configured horizontally, with the web traveling between them from top to bottom, with the coating remaining in the melt pool between the rolls.

The amount of coating transferred to the web depends on several factors, including web material, coating viscosity, and web surface, and can be controlled by adjusting the speed of the steel roll relative to the web speed. as pressure between the rollers.

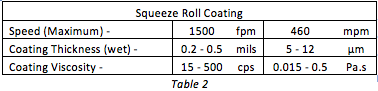

Table 2 (below) shows typical operating speeds, coating application rates, and coating viscosities for a twin-roll extrusion coater.

A variation of this coater uses two precision steel rolls to form the nip (Figure 2). In this case, the amount of coating transferred is controlled by the gap formed between the two rolls as the web passes between them. In this case, the coating thickness and viscosity can be much higher than those shown in Table 2.

Extrusion coaters are relatively inexpensive coaters that are easy to operate and maintain and offer a good speed range. It's also easy to switch from one coat to another/clean up, especially if the coater is designed with interchangeable pans. While it has a limited coat deposit range, it is easy to vary coat weights within that range. While there are several factors that can affect coating usage, it can be easily controlled. It has a limited viscosity range.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative