Comparison of Aluminum Film thickness Measurement Instruments

Did you know that aluminum can absorb twice as much collision energy as steel? The Aluminum Association reports, “Sterling, aluminum, absorbs twice the crash energy of steel and performs well in accidents. Aluminum crash barriers fold up like accordions to dissipate and move energy away from vehicle occupants.” Aluminum also has advantages in stopping distance, handling and performance.”

Ironically, aluminum has light weight, which helps fuel efficiency in vehicles, and is also reflective, which helps improve energy production from solar cells. Aluminum can also be recycled and reused. Aluminum demand totaled more than 26 billion pounds last year, in North America alone, due to environmental concerns involving greenhouse gas emissions and sustainability.

Due to the industry's commitment to sustainability and environmental impact, the Aluminum Association publishes Environmental Product Declarations (EPDs) for various aluminum products. These statements include specifications for hot-rolled aluminum (sheet and plate rolled at high temperatures). Plates and thicker gauge plates are available for structural applications including aircraft and aerospace. Also includes cold-rolled aluminum (hot-rolled sheet that was previously rolled at or near room temperature to make the metal thinner and stronger). This type is commonly used in the manufacture of building roof and siding panels, shipping panels and beverage cans.

As you can imagine, accurate thickness measurements are required to ensure product uniformity, achieve high product quality and meet EPD. Aluminum that is too thin or too thick can cause problems for manufacturers who use aluminum sheet in their designs, and it can also reduce the profitability of aluminum producers.

That's why aluminum producers utilize thickness measurement tools, measurement systems that provide fast, accurate, non-contact and non-destructive thickness and coating weight measurements. Thickness gauges provide precise, real-time measurement of aluminum and aluminum alloys during high-speed production processes to help meet tight tolerances, ensure finished products have specific mechanical properties, and optimize rolling mill control.

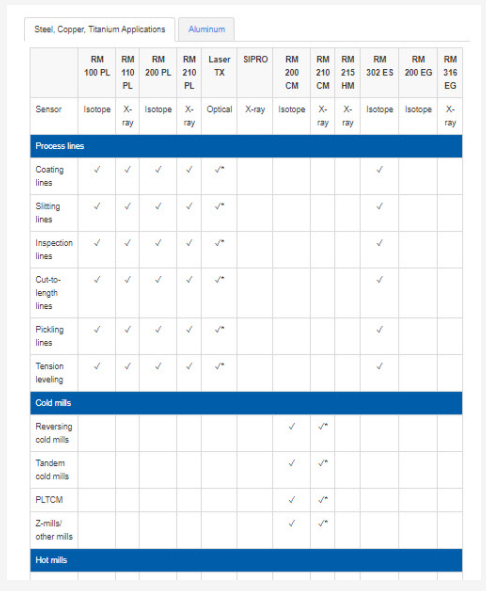

But depending on the application, there are different kinds of Thickness Gauges. Foil mills, processing plants, cold rolling mills, hot rolling mills and plate mills all have sensor technology.

It can get a little confusing. So here is a comparison chart to help sort out the types of metal Thickness Gauges available to aluminum producers.