Film Thickness Gauges for steel applications

Just fifty years ago, world production was less than 500 million tonnes, according to the world steel association. They attribute this growth to newly industrialized nations such as Brazil, CHINA, India, Iran, and Mexico.

That's a lot of steel. But no wonder. Steel is versatile and can be found all around us, from roads and railways, to oil and gas wells and wind turbines, to skyscrapers and bridges, to packaging, appliances and even our tableware.

Hot and cold rolling mills need to deliver steel that precisely meets the required specifications. Can you imagine if the steel used for a wind turbine support tower or a road barrier is too thin? This could be the cause of disaster.

That's why hot and cold rolling mills utilize Thickness Gauges and measurement systems to provide fast, accurate, non-contact and non-destructive thickness and coating weight measurements. Precise measurements are required to ensure product uniformity and achieve high product quality. Thickness gauges provide accurate, real-time measurements during the high-speed production of steel plates and plates to help meet tight tolerances and ensure specific mechanical properties in finished products.

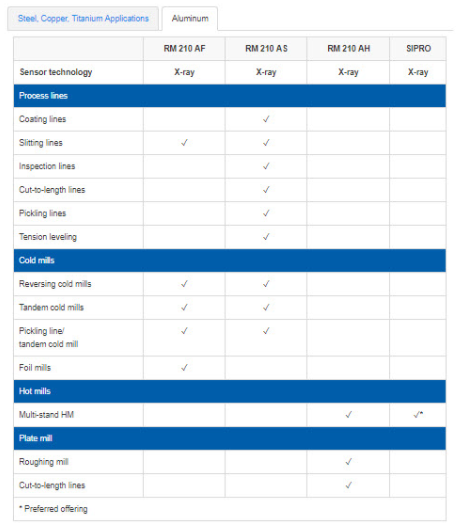

But depending on the application, there are different kinds of Thickness Gauges. There are gauge hot rolling mills, non-contact Thickness Gauge cold rolling and production lines, non-contact Thickness Gauge Hot Plate lines, and optical Thickness Gauges. It can get a little confusing. So here is a comparison chart to help sort out the types of metal Thickness Gauges that can be used on production lines, cold rolling mills, hot rolling mills, and plate mills.

- 1Which Coating Thickness Gauge is Right for You?

- 2Film thickness determination of films with TJIKN instrument

- 3GB/T13452.2-2008 Determination of film thickness of Paints and varnishes [text version]