Test paint adhesion strength using an impact meter

The term "coating" is used to distribute fluids on strong materials. Items attached to substrates in uninterrupted or disrupted films by one of several application strategies are fluid coatings. It is a strong coating film after drying of the fluid coating by evaporative means or release (crosslinking) by oxidation, warm, bright light or other techniques.

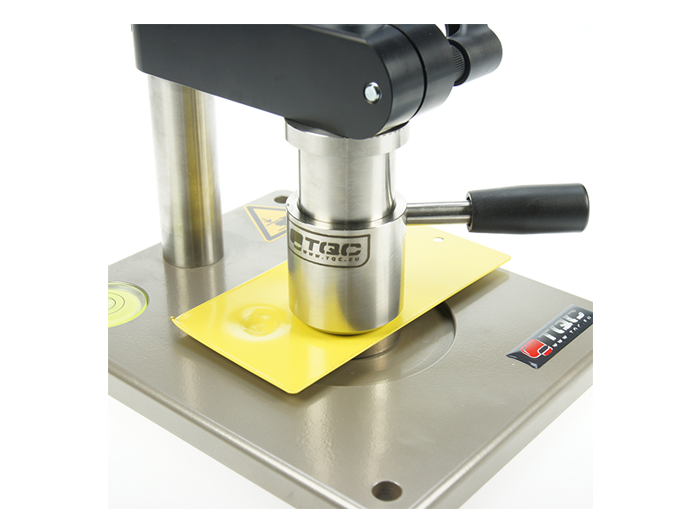

Impact testing machines for paints and coatings are used to check their resistance to maturation and any impact exerted on them. The impact analyzer accurately measures the impact of maturation on the coating, including fracture type, adhesion, adaptability, and reverse testing of materials to determine impact surface protection from impact surface entry and damage to plastics, fiberglass, metals, etc. Extra damage, pressed planks and tar.

Impact Resistance Tester for Coatings - Direct is a proficient testing device that is valuable for evaluating coatings for split development; cut off; grip and dexterity and other related issues. Frame the metal in the metal plate by means of a drop indicator weight with hemispherical ends. The result is an outgoing check. It is composed according to the general standards of ASTM D2794-93 (2010), ISO 6272-1:2011.

An example of a natural coating in a test setup is coated on a thin metal panel and set up for at least four tests to accurately quantify the results. After the impact of the impact force, the standard weight measurement falls from the height to the blow deforming or pulverizing the coating and material as the coating bends. Space can be eviction or interruption.