A Foreigner's Understanding of Coat Hardness

With over 12 years of detailed design and coating experience in Malaysia with various products from world-class partners, we wanted to explain how the hardness of a material affects its ability to scratch a surface. Some recent coating systems claim a hardness of 9, but our experience with coatings suggests that this claim is unlikely to be based on some very basic science.

Let's start with a general definition; the hardness scale is defined by the Mohs scale.

"Scratch hardness is related to the breaking of chemical bonds in materials , the creation of surface microcracks or the replacement of atoms in minerals (in metals).

The Mohs hardness scale was developed by Frederich Mohs in 1822.

The scale is a chart of the relative hardness of various minerals (1 - softest to 10 - hardest). "- as defined by the Mineralogical Society of America.

The softest mineral commonly found is talc (baby powder with a ratio of 1 on the Mohs scale), and the hardest substance found in nature is diamond (rated at 10 on the Mohs scale). The next objects of similar hardness to No. 9 diamonds are rubies and tungsten carbide (commonly used in drill bits). Synthetic diamond or cubic zirconia, size 8.

As far as science goes, there is no quartz coating with a rating of 9. In comparison, most minerals above 5 are fairly hard materials that don't scratch easily. Coatings are designed to protect a vehicle's paintwork from common debris (mud/sand/dust) and moisture.

There is also a general concern among most car owners about possible damage from vandalism, including:

a) Coins (3.5 on the Mohs scale)

b) Blades (5.5 on the Mohs scale)

c) Nails (Mohs scale 2.5)

The key to understanding the Mohs hardness scale is simple: an object with a lower hardness (low Mohs number) will not be able to scratch a harder object (with a higher Mohs number). For example, a diamond (10) may scratch anything, but a coin (3.5) will not be able to scratch a ruby (9). Known: only diamonds can cut diamonds (10)!

But to take this a step further; the Mohs scale is for RAW minerals and metallic elements; not paint. Some paint professionals claim that their coatings have a hardness of 9. If this is true, synthetic diamonds (8 cubic zirconia) will not be able to scratch this coating! Only other elements such as ruby, tungsten carbide, and real diamonds can scratch these coatings, which have a claimed hardness of 9.

"Glass/quartz/ceramic/crystal coatings require a hardness of 9, which is practically impossible."

The paint formula is tough enough to withstand most of the common elements a car owner faces on a daily basis. A SiO2 coating will cover most of your protection needs. It's extremely unlikely that people would intentionally wreck a car with a real diamond ring, real ruby bracelet, or tungsten carbide drill!

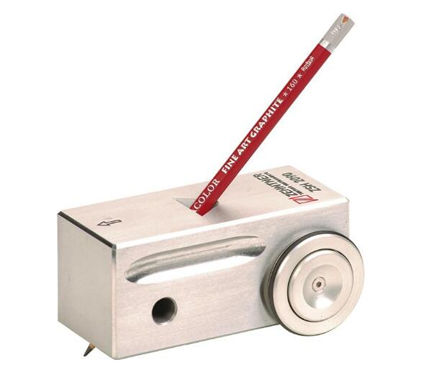

Another common test for coating hardness is the pencil hardness test or Wolff-Wilborn test. The test is performed in a laboratory setting where pencils of various hardness are used to intentionally scratch a surface or coating to see how well it resists scratching. Typically different pencils have a maximum pressure of about 2 lbs/ft, and the hardness rating (H) is based on the pencil used. However, these tests are not representative of real-world conditions. Even a bad car wash, such as using a damaged rag, can scratch the finish on your car.

Paints and Waxes

Coatings are not designed to make a car completely indestructible, but they provide a layer of protection against UV rays and debris while allowing longer gaps between details than using wax as a finishing product. Wax usually only lasts 2 to 3 weeks in Malaysian weather. SiO2 coatings are the most versatile and can be applied to vehicles with good protective properties. Unlike wax, the coating lasts for over a year. It also has amazing clarity and shine while requiring minimal maintenance. A weekly wash is all that is needed to maintain a shiny look. No need for buffing or waxing every month.

To answer the question we asked at the beginning; the coating is designed to be finished and locks in any detail work so you don't need to wax or polish the exterior. The coating is designed to be hydrophobic and resistant to debris, but it doesn't make them completely impervious to scratches due to abuse such as vandalism or deliberate scraping.

Single coating (LEFT) and multicoating (7 layers) were scratched using a coin (right). Coatings cannot withstand objects with a hardness of 9, as claimed by some coating professionals. The coins used to scratch both coatings had an average hardness of just 3.5 on the Mohs scale.

Just using a nail with a hardness of 2.5 Moh, scratches were still visible on both single (LEFT) and multiple coated samples (RIGHT).

- 1Film hardness testing method: pendulum hardness, pencil hardness, etc

- 2ISO 15184 Pencil method to measure the hardness of paint film

- 3Analysis of hardness measurement by ASTM D3363 pencil method

- 4Pencil Hardness Tester test procedure, application and different Hardness Pencil introduction

- 5Pencil hardness testing of film

- 6Ceramic Coated Pencil Hardness Test

- 7Relevant standards for pencil Hardness Testers

- 8What is a pencil hardness test?

- 9What performance subjects are tested for water-based floor coating materials and how do they meet the standards?