Coating Thickness Gauge for coated Film thickness measurement in vehicle evaluation

Coating Thickness Gauge is required for vehicle evaluation

Automotive Professionals • Automobile and Vehicle Operations • Auto Body Repair • Automobile and Vehicle Repair

Today, professional vehicle evaluations are only possible with the use of coating Thickness Gauges. Users in the motor vehicle industry need these gauges to perform professional damage reports or valuations, lease vehicle restoration, purchase used vehicles, and inspect and document body and paint jobs.

The reason is obvious: the value of a vehicle after an accident and its restoration value depend on any possible prior damage. That's why users and their orderers want to find out whether body and paint repairs have been carried out professionally and correctly. The QNix® coating Thickness Gauge is the tool of choice for this purpose.

For decades, auto professionals, auto dealers and body repair shops have successfully used solutions from Dr. Automation Nix. Backed by many years of experience, the QNix® product line offers the right coating Thickness Gauge for every application: from quick and easy measurements to software support documentation for evaluation by professionals.

Application of QNix® in Vehicle Evaluation Applications

work effectively

Efficiency is also an important part of vehicle evaluation. The overall expense is high, depending on how many measurements need to be taken on the vehicle and whether they need to be documented.

The QNix® Coating Thickness Gauge allows you to take very fast ergonomic measurements, even if you need to record several values consecutively. You don't need to turn on the device first. Just locate, measure and read. For safe and fast documentation, our CarCheck System Plus has useful automatic features that you can configure in advance.

Detect tin layer

After an accident repair, even professional repairs, a coating up to 3mm thick can be found on the car body. They can even be 5mm thick for older vehicles. This is usually due to the tin layer used to smooth the surface after dent removal. The QNix® Coating Thickness Gauge is also available as a dual device. You can use them to determine the total coating thickness on steel (Fe) and the coating thickness on tin plating (NFe). You can also determine the overall coating thickness for thicker tin applications with a measurement range of up to 5 mm.

Protect paint during measurement

When measuring paint thickness, place the paint Thickness Gauge on various parts of the vehicle. The measuring tips of our measuring devices are fitted with a polished ruby to prevent scratches and marks on painted surfaces.

precise and accurate

To guarantee accurate measurement results, you need to calibrate your coating Thickness Gauge before use. This adapts them to the properties of the underlying substrate. During vehicle measurements, this was not possible because there was no uncoated substrate.

The QNix® Coating Gauge features a measurement technology that, combined with a factory calibration stored in the device, ensures precise and correct measurement results. For applications in the motor vehicle sector, no foil calibration is required. All you need to do is a simple zero point adjustment (initialization) to the reference standard provided by the device.

easy to use

Technology tools are becoming increasingly complex in order to meet specific needs. Coating Thickness Gauges in particular often serve many functions because they are used in various fields and need to fulfill many requirements.

That's why the QNix® Coating Thickness Gauge is not only high quality and made in Germany, but also easy to use. We meet this requirement by focusing on ease of use, including fast and simple coating thickness measurement and software supported documentation of results.

Documentation software supported by PC

When creating a valuation or damage report, or in the case of rental vehicle restoration, you may need to document coating thickness measurements if the results affect the value of the vehicle. In particular, the relationship of the measured values to certain areas of the vehicle will help you to explain, for example, third party value drops.

Our CarCheck System Plus helps you do just that. You can create an order with all relevant vehicle and customer information, transfer photos to the order and position your recorded measurements as required. All of this information is stored in a database on your computer so that you can retrieve it later.

Recommendations for this field

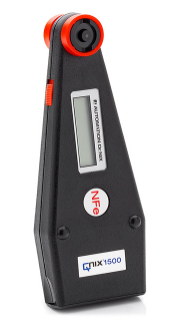

| QNix®1500 |  |

| |

| QNix®4500 |  |

| |

| CarCheck System Plus | |

|  |

-

-

QNix 9500 Coating Thickness Gauge, basic$ 1194.00

-

-

-

-

-

Qnix 5500 Coating Thickness Gauge$ 1044.00

-

-

- 1Nondestructive measurement Coating thickness

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 4Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- 5Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 6Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- 7Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 8Basic principle and application scenario of steel Coating Thickness Gauge

- 9Principle and Application Analysis of Coating Thickness Gauge