Preparation of Richter Hardness Meter Before Use

In order to ensure the measurement accuracy, in the process of making the surface of the sample, the influence of heat, cold working and magnetism on the hardness surface should be avoided as much as possible. The sample workpiece temperature needs to be lower than 120°C. The relevant preparations before using the Leeb Hardness Tester are as follows:

3.1 Weight requirements

The weight, thickness and solidity of the sample workpiece will directly affect the measurement of the hardness value. To obtain an accurate hardness value, workpiece selection is particularly important, and the surface hardness of the workpiece needs to be uniform.

For heavy test pieces weighing more than 5kg, no support is required;

* For medium-sized samples with a weight of 3 to 5KG, it needs to be placed on a flat and solid plane, and the test piece needs to be placed absolutely stably without any shaking;

For light samples weighing less than 2KG, it needs to be tightly coupled with a solid support. The two coupling surfaces need to be flat and smooth, and the amount of coupling agent should not be too much. Need to be perpendicular to the coupling plane;

* When the test piece is a large-area plate, long rod, or curved piece, even if the weight and thickness are large, it may still cause deformation and instability of the test piece, resulting in inaccurate test values, so it should be reinforced or supported on the back of the test point.

3.2 Roughness requirements

The roughness of the sample surface will directly affect the measurement of the hardness value. In order to reduce this measurement error, the sample surface should be polished and have a metallic luster. The roughness value (Ra) needs to be ≤2um. Note: The rougher the surface of the sample, the smaller the hardness test value.

3.3 Cleaning requirements

In order to ensure the accuracy of the test, the surface of the workpiece to be tested needs to be clean, free from oil, dust and coatings.

3.4 Stability requirements

To avoid position shifting during measurement, the workpiece should be firmly fixed and the test surface should be perpendicular to the impact direction. Due to the impact of the impact body, the test area may be deformed or vibrated.

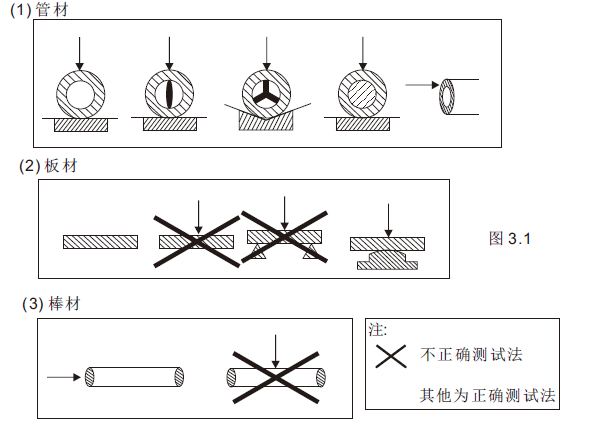

For large pieces, strips (rods) or workpieces with curved surfaces, the measured hardness is lower than the actual hardness. It is recommended to use the method in Figure 3.1 for measurement.

3.5 Surface workpiece

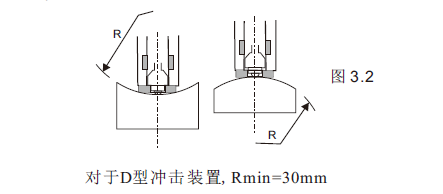

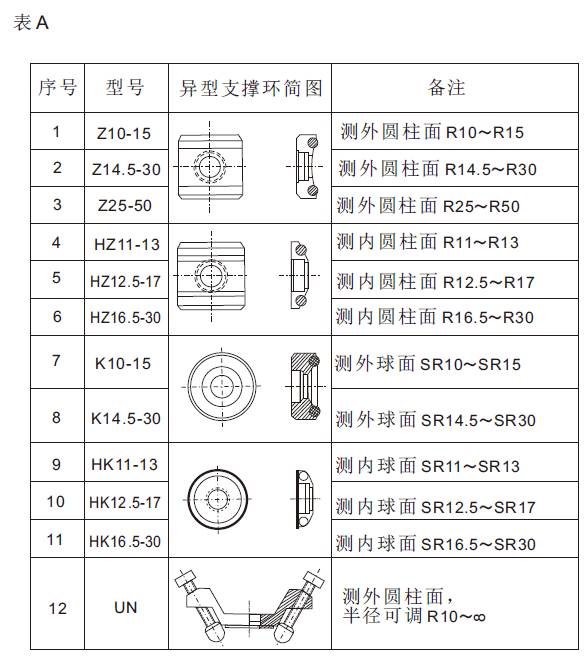

The larger the radius of curvature of the workpiece surface, the easier it is to handle the hardness. Under normal circumstances, for workpieces with a curved surface radius greater than 30mm, the standard support ring on the impact device can be used for direct measurement. If the radius of the curved surface of the sample block is less than 30mm, a small support ring should be selected. See Appendix A

This article is mainly excerpted from "Leeb Hardness Tester Instruction Manual"

- 1Read the Leeb Hardness Tester in one article

- 2Leeb Hardness Tester different hardness system difference

- 3Frequently Asked Questions about Hardness Testers in 2022

- 4What products is the Leeb Hardness Tester with D probe suitable for measuring?

- 5Basic knowledge of hardness testing

- 6Factors Affecting the Accuracy of Leeb Hardness Tester Testing

- 7Leeb Hardness Tester measurement requirements

- 8Test method for roll hardness

- 9How many Hardness Testers do you know?

-

-

-

PRLH150 Leeb Hardness Tester$ 259.00

-

-

-