Hardness meter calibrating and maintenance

After the Leeb Hardness Tester has been used for a period of time, due to improper use or other problems that will affect the accuracy of the instrument, it needs to be recalibrated and maintained. This article mainly gives a brief introduction to the calibration and maintenance of the Leeb Hardness Tester.

1. Instrument Calibration

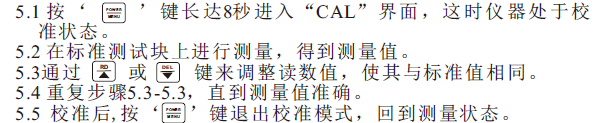

After a period of use, especially after testing some relatively rough materials, the dots of the impact body may be a little worn, which will inevitably lead to a more or less affected measurement accuracy. In this case, the instrument needs to be recalibrated as follows:

Note: If the error of the instrument is within the basic range, in order not to affect the long-term stability of the instrument, please do not calibrate it lightly.

2. Maintenance and repair

1) After 1000-2000 times of use, clean the conduit and impact body of the impact device with a nylon brush. When cleaning the conduit, first unscrew the support ring, then take out the impact body, and screw the nylon brush into the tube counterclockwise. Pull it out after reaching the end, repeat this 5 times, and then install the impact body and support ring;

2) After use, the impact body should be released;

3) It is strictly forbidden to use various lubricants in the impact device.

4) When the standard Rockwell hardness block is used for verification, if the error is greater than 2HRC, it may be that the ball head is worn out, and replacement of the ball head or impact body should be considered.

The above is about the calibration and maintenance of the Leeb Hardness Tester. For details, please refer to the "Leeb Hardness Tester Instruction Manual"

- 1Frequently Asked Questions about Hardness Testers in 2022

- 2Test method for roll hardness

- 3How many Hardness Testers do you know?

- 46 Tips for Using a Hardness Tester

- 5ASTM D2240 Rubber Properties, Hardness Testing

- 6ASTM D2240 Rubber Properties, Hardness Tester Hardness Testing

- 7What are the test subjects for perchlorovinyl resin anti-corrosion coatings?

- 8Controlling Variables Affecting Screen Printing Ink Deposition

- 9The principle and subdivision type of Vickers Hardness Tester