Viscosity measurement

On-line viscosity measurement provides continuous, real-time readings of fluid viscosity during processing, thus providing a method for automated process fluid viscosity control. While it is difficult to control all factors in a process that can affect fluid viscosity (such as temperature, air bubbles, shear history, turbulence, etc.), good control can be achieved if these factors are kept relatively constant. This article introduces the application of on-line viscosity measurement and its realization method. We first discuss the viscosity problem.

Base

Viscosity is a property often considered by process engineers, but rarely fully understood. It's not usually a topic covered in detail in many engineering courses. Most engineers know what viscosity is, but may not be able to explain it, or even understand the full impact of the measured quantity. Scientifically, viscosity is the property of a fluid that makes it resist flow.

For materials that flow during processing (pumping, spraying, or coating) or end use (such as shampoo, detergent, or paint), it is important to consider the flow characteristics, or viscosity, of the material. Engineers and quality control personnel need a way to measure viscosity so they can quantify whether a material will flow the way a process or application requires.

Plant personnel can indicate the viscosity or "thickness" of a material by looking at it, rubbing it between their fingers, or dripping it from a stick or spatula. The actual "measurement" of this material property eventually evolved into a more scientific method by using a cup with a hole in the bottom and a stopwatch to measure the time it takes for the fluid to drain. Cups, such as efflux cups, are relatively cheap and easy to use. This type of test uses gravity to force the fluid out of the cup. Shearing of the fluid occurs at the orifice at the bottom of the cup. As the level in the cup drops, the shear rate at the orifice decreases because the remaining fluid weight in the cup is lower. This type of measurement is called kinematic viscosity. This method is one of the earlier quality control (QC) tests, checking viscosity in a quantifiable way.

However, the cup method cannot always successfully differentiate between proven acceptable material and marginal or even poor material due to variations in shear rate. It is important to understand what is defined as "shear rate" and how it affects the viscosity of a fluid. Imagine that the fluid you want to test is sandwiched between two plates separated by a known distance. Keep the bottom plate stationary and move the top plate at a defined velocity, the shear rate being the ratio of the velocity V of the moving plate to the distance of the separating plate, X. Using a Rotational Viscometer running at different speeds can partially simulate what happens to the fluid during processing. This analytical procedure for instrumentally simulating shear effects is key to predicting flow behavior.

The Rotational Viscometer (Figure 1) is a widely accepted tool for viscosity measurement in most industries. The spindle of the Rotational Viscometer rotates at various fixed speeds while inserted into the liquid, thereby continuously shearing the material at a defined shear rate. Simultaneously, the viscometer measures the amount of torque resistance experienced by the spindle at each rotational speed. This torque measurement is quantified as "shear stress", which acts on the surface area of the immersed part of the spindle. These two key concepts - torque resistance and shear action - are combined in a single equation that defines apparent or dynamic viscosity as the ratio of shear stress to shear rate.

Figure 1. Couette-type viscometers with defined shear rate measurements are typically used when measurements comparable to laboratory-type measurements are required

The units of measurement used to quantify rotational viscosity are centipoise (cP) in the Western Hemisphere, and milliPascal-second (mPa-s) in other countries, although there is some degree of overlap in usage. The good news is that the two units are interchangeable, since 1 cP equals 1 mPa-s. There is a method for viscosity measurement of Newtonian materials using dynamic and kinematic methods, using the following formula: Dynamic Viscosity = Kinematic Viscosity × Density (for more information on the fundamentals of viscosity, see Viscosity: The Basics, Chemical Engineering., 2009 August, pp. 34-39).

process measurement

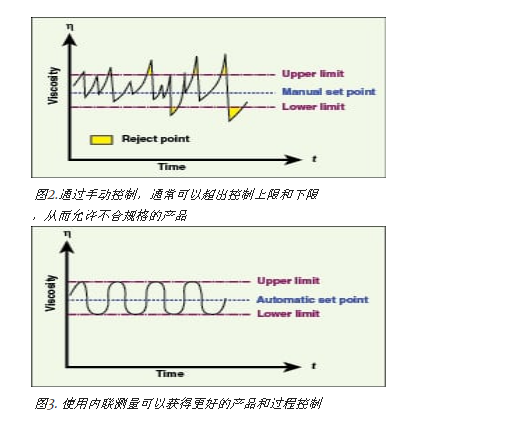

Automatic control of process fluid viscosity ensures consistent product, reduces product hold time, and can eliminate human error and costly sample testing (Figures 2 and 3). In addition, it provides a complete record of how the process changes over time, rather than just at one point in time. In a factory environment, there are many ways to measure viscosity, such as through Rotational Viscometers, vibrating elements, and falling objects. Knowing whether true, defined shear rate measurement is required, or whether you are really just looking for set point control, is beneficial in selecting the appropriate type of instrument for your application.

Process measurements are performed online or in the process loop. Benchtop Rotational Viscometers can be used for off-line or near-line measurements, where a sample of the process fluid is drawn and tested under controlled conditions (using the same bath temperature, shear history, shear rate, etc.). The in-line viscometer is immersed in the process stream and measures continuously at the process conditions. Installation can be done in side stream, main flow or tank. When deciding on an installation, consider how the equipment will be cleaned and maintained, if necessary.

It is also important to ensure a representative sample of the fluid being measured. Possible concerns about stratification, mixing and turbulence should be considered. The instrument will measure the product it is in contact with, so ensuring that the liquid the instrument "sees" is the material you want to measure is the first consideration. The requirements of laboratory and process environments are different, so it is unlikely that the same equipment will be used for both types of measurement or will produce exactly the same measured values. However, if handled properly, the results of laboratory and in-line measurements will follow the same trend, making in-line measurements helpful in ensuring consistent production quality.

- 1Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 2Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 3Application of Rotational Viscometer in juice viscosity test

- 4Working Principle, Classification and Application of Capillary Viscometer

- 5Principle, Characteristics and Application of Dial Viscometer

- 6Basic Principle and Application of Ceramic Viscometer

- 7Principle, Characteristics and Application of QND Viscometer

- 8Determination of epoxy resin viscosity by Rotational Viscometer

- 9Rotational viscometer selection suggestions