Photoelectric Turbidity Meters for Varnish Transparency Testing

Transparency is the ability of a substance to transmit light. Transparency can indicate whether varnishes, varnishes, paints and thinners contain mechanical impurities and suspended matter. In the production process, the purity of various materials, the mixing of mechanical impurities, the compatibility of resins, the precipitation of drier and the infiltration of water will all affect the transparency of the product. Products with a turbid and opaque appearance will affect the gloss and color of the film after formation, as well as reduce the resistance of the adhesion to chemical media.

There are two specific detection methods: visual inspection method and instrument method.

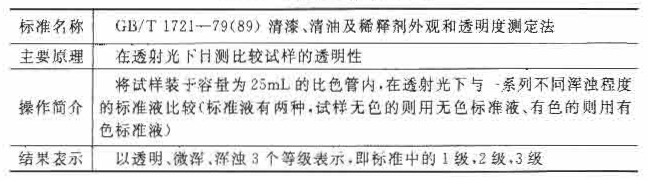

(1) Visual inspection method as shown in the table below.

(2) Instrument method

A photoelectric Turbidity Meter is used to eliminate the interference to the visual inspection results due to the different shades of the product, and to improve the accuracy of the test. The light emitted by the light source S is scattered light due to the influence of impurities or suspended matter in the test tube T, which is reflected by the reflector A and transmitted to the photoresistor to be received. Select a frosted plexiglass rod with a refractive index of approximately 1.5 as the standard turbidity of 100, zero it with distilled water, and then measure the turbidity of the sample, expressed in numbers.

- 1Common types and application differences of STIP-scan

- 2What is haze or turbidity?

- 3Turbidity Meter/Turbidity Sensor FAQ

- 4What is a turbidity meter and how does it work?

- 5Water quality testing instrument FAQ collection

- 6Why is silicone oil important in turbidity meter measurements?

- 7How to measure the turbidity of a liquid?

- 8Testing water quality with turbidity instruments

- 9Techniques for measuring turbidity in water